Cookies are not enabled on your browser.

Cookies are not enabled on your browser.Cookies are required for our site. Please enable cookies in your browser preferences to continue.

- Barcode / RFID / Vision

- Bulk Wire & Cable

- Cables (Terminated)

- Circuit Protection / Fuses / Disconnects

- Communications

- Drives & Soft Starters

- Enclosure Thermal Management & Lights

- Enclosures & Racks

- Field I/O

- HMI (Human Machine Interface)

- Hydraulic Components

- Motion Control

- Motor Controls

- Motors

- Pneumatic Components

- Power Products (Electrical)

- Power Transmission (Mechanical)

- Process Control & Measurement

- Programmable Controllers

- Pushbuttons / Switches / Indicators

- Relays / Timers

- Safety

- Sensors / Encoders

- Stacklights

- Structural Frames / Rails

- Tools & Test Equipment

- Valves

- Water (Potable) Components

- Wiring Solutions

- Retired Products

- Programmable Logic Controllers

- Productivity1000 PLCs

- Productivity2000 PLCs

- Productivity3000 PLCs

- ProductivityCODESYS

- LS Electric XGB Series PLCs

- ProductivityOpen

- CLICK PLCs

-

Do-more H2 PLCs or

Do-more T1H Series - Do-more BRX PLCs

- C-more Touch Panels

- AC & DC Drives

- Motion Control Components

- Servos

- StrideLinx

- Pneumatics

Configuration Utilities

- PLC Family Selector

- P1000 PLC Systems

- P2000 PLC Systems

- P3000 PLC Systems

- ProductivityCODESYS

- CLICK PLC Systems

- Do-more® BRX PLC Systems

- LS-Electric® XGB PLC Systems

- Productivity®Open Systems

- AC Motors

- Datalogic® Safety Light Curtains

- LS-Electric® Servo Systems

- Nitra® Pneumatic Grippers

- Object Detection (Sensors)

- PAL Controller Configurator

- Precision Gearbox Selector

- Protos X® Field I/O

- Quadritalia® Modular Enclosures

- Stellar® Soft Starters

- Stepper System Selector

- SureFrame T-slot Extrusion

- SureMotion® XYZ Gantry

- SureServo2® System Selector

- SureStep® Linear Actuators

- Timing Belts & Pulleys

- Werma® Stacklights

- ZIPLinks

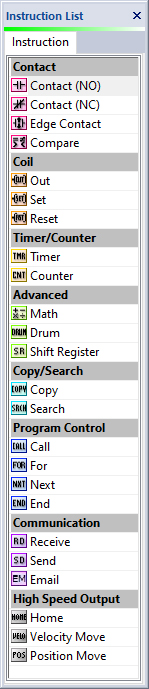

FREE CLICK Software: Instruction List

(with full help files) for a more complete understanding of how each instruction works.

High Speed Output and Email instructions only available with CLICK PLUS PLCs

High Speed Output and Email instructions only available with CLICK PLUS PLCs

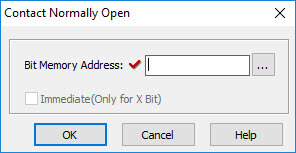

Contact Normally Open

The Normally Open Contact mimics the behavior of a physical contact and changes in response to the status of a Bit Memory Address. The Normally Open Contact is ON when the related bit is ON.

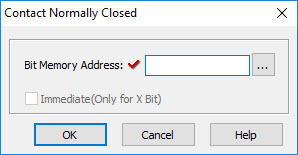

Contact Normally Closed

The Normally Close Contact mimics the behavior of a physical contact and changes in response to the status of a Bit Memory Address. The Normally Closed Contact is OFF when the related bit is OFF.

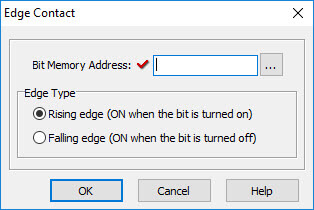

Edge Contact

The Edge Contact turns ON when the related bit transitions from OFF to ON (Rising Edge) or ON to OFF (Falling Edge).

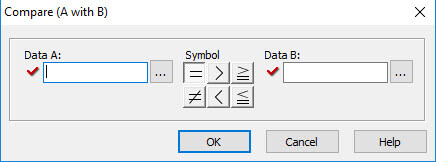

Compare Contact

The Compare A with B instruction uses a Mathematical Operator as a basis of comparison of two data values. A mathematical statement is developed using the instruction dialog. When the Data A value satisfies the selected mathematical relationship with Data B, the associated Bit Memory Address is turned ON.

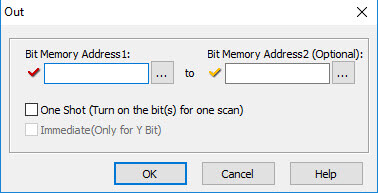

Out Coil

An Out instruction turns ON its associated Bit Memory when the status of the rung is true. The Out instruction turns OFF its associated Bit Memory when the status of the rung is false. An Out instruction is capable of turning on and off more than one Bit Memory Address at the same time.

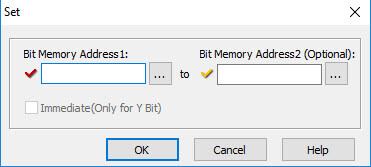

Set Coil

The Set instruction turns ON the associated Bit Memory when the status of the rung is true. The Set instruction can turn ON more than one Bit Memory at the same time.

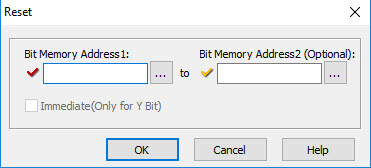

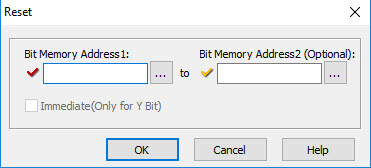

Reset Coil

The Reset instruction will turn off the associated bit memory when the status of the rung is true. A Reset instruction can turn off more than one bit memory at the same time.

Timer

An ON Delay Timer measures a user-specified time duration that begins with a transition of the enable rung from OFF to ON. Beyond this transition point, the Timer increases the Current Value until it reaches the Set Point, when the Timer Bit is turned ON.

An OFF Delay Timer measures a user-specified time duration that begins with a transition of the enable rung from ON to OFF. Beyond this transition point, the Timer increases the Current Value reaches the Set Point, when the Timer Bit is turned OFF.

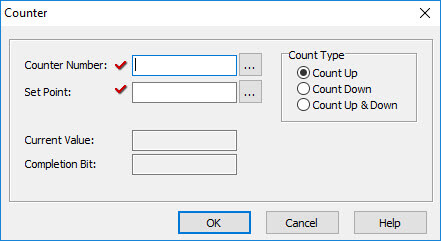

Counter

When enabled, a Counter instruction counts up or down (depending on user settings) until it reaches the Set Point. The Counter counts in response to the transition from OFF to ON of the enabling rung. If the user selects Count Up & Down, the Counter will have two enabling rungs, one for up counts and one for down counts.

The current count is held in the register shown in the Current Value field. When the Current Value reaches the Set Point, the Completion Bit is turned ON. The Completion Bit is turned OFF when the Reset rung is enabled.

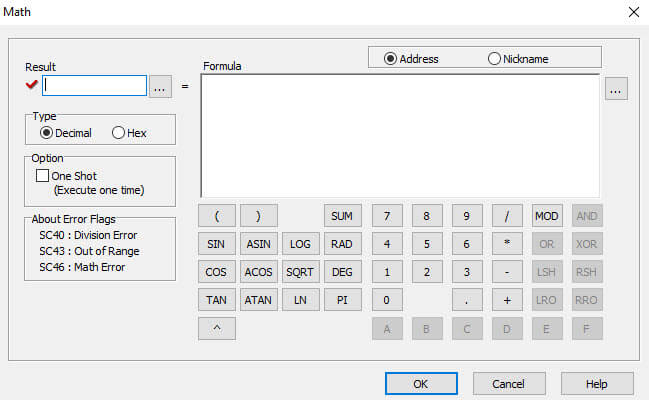

Math

The Math instruction serves as a powerful calculator to perform mathematical operations during the execution of the Ladder Program. The formula area is used to develop the mathematical expression that will be solved during the CPU scan. The mathematical expression can be developed using the onscreen keypad, the keyboard, and Address Picker, combining constants and stored variable values, as necessary for the application.

Two sets of mathematical operators are available within the Math instruction: decimal and hexadecimal. When the Decimal radio button selected,the available operators include: standard arithmetic and algebraic operators, parentheses for grouping terms, and transcendental functions and operators. When the radio button for Hex is selected, the logical operators: AND, OR, XOR, and the bit operations: Shift Left(LSH), Shift Right(RSH), Roll Left(LRO) and Roll Right(RRO) are made available. The Sum and Modulo operators are available for either decimal or hexadecimal data values.

Parenthetical expressions can be nested up to eight levels deep. If the Floating Point Data Type is employed in any operation, then all operations will be based on Floating Point math. The Result will be stored in the data format selected for the Result.

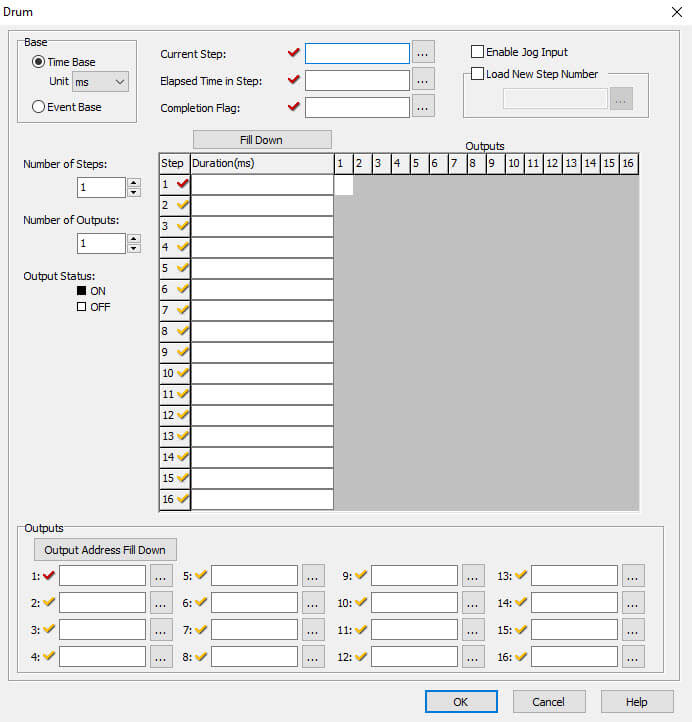

Drum

The Drum instruction is used to simulate an electro-mechanical drum sequencer. It works on time base or event base.

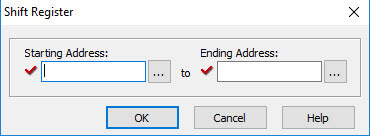

Shift Register

The Shift Register instruction shifts a range of control bits with each OFF-to-ON transition of the Clock pulse. If the starting address is lower than ending address the shift register will shift from left to right. If the ending address is lower than starting address then shift register will shift from right to left.

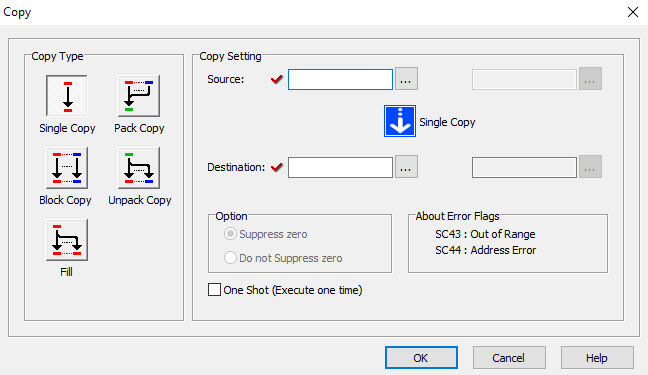

Copy

The Single Copy instruction is used to copy a value from its Source location to a specified Destination register. The Source location can be another register, identified by its Memory Address, or a constant value entered in this dialog. The Block Copy option is used to copy values from a block of Source locations to a block of Destination registers. The Source location of the data or text is identified by a range of memory addresses, and only the first register of the destination range is required. The Block Copy opion also allows the copying of numerical text values (strings) to one or more data registers as integer values.

The Fill option is used to copy a value from a single Source location to a specified range of Destination registers. The Source location can be a register, identified by its Memory Address, or a constant value typed directly into the Source field in this dialog.

The Pack Copy mode combines the status of up to 16 Source Bit Memory Addresses (X, Y, C, T, CT or SC) and copies the combined status into a Destination Data Register (DH or YD).

The Unpack Copy mode copies the data in a Source Data Register (DH only) to up to 16 Destination Bit Memory Addresses (Y or C).

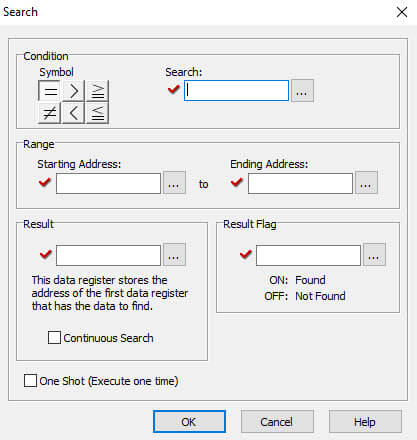

Search

The Search instruction is used to search for a data value that meets specified conditions and that is located within a specified range of data registers. A successful search returns the Memory Address of the value that satisfies the conditions.

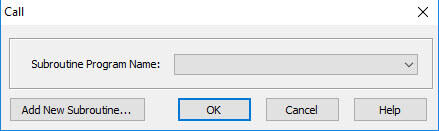

Call Instruction

The Call instruction is used to call a Subroutine program from the Main Program. The Call instruction resides in the Coil Area of the Ladder Program. A Subroutine program must have a Return instruction to return to the Main Program.

Return

There is no dialog box needed for the Return Instruction, the instruction is either inserted at the current rung, or it can be "dragged and dropped" at the desired position. All Subroutine programs must have at least one Return instruction to return to the Main Program. The Return instruction resides in the Coil Area of the subroutine program..

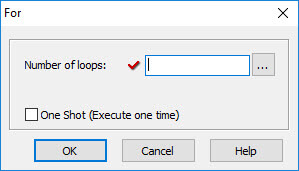

For Instruction (For-Next Loop)

The For instruction indicates the starting point of a For - Next loop, and based on its user setting, determines how many times the For - Next loop will be executed. Between the For instruction rung and the Next instruction rung, place the rungs of logic that should be repeated multiple times. Placing one For-Next loop inside another For-Next loop is not permitted.

Next Instruction (For-Next Loop)

The Next instruction doesn't need a dialog box, the instruction is either inserted at the current rung, or it can be "dragged and dropped" at the desired position. The Next instruction indicates the end of a For loop. The ladder program will either loop or continue depending on the settings of the consesponding For Instruction. The Next instruction must be the only instruction on its rung. No enabling contacts are allowed on the same rung with the Next instruction.

End Instruction

The End instruction doesn't need a dialog box, the instruction is either inserted at the current rung, or it can be "dragged and dropped" at the desired position. The End instruction indicates the end of the Main Ladder Program. No ladder code is allowed beyond the End Instruction.

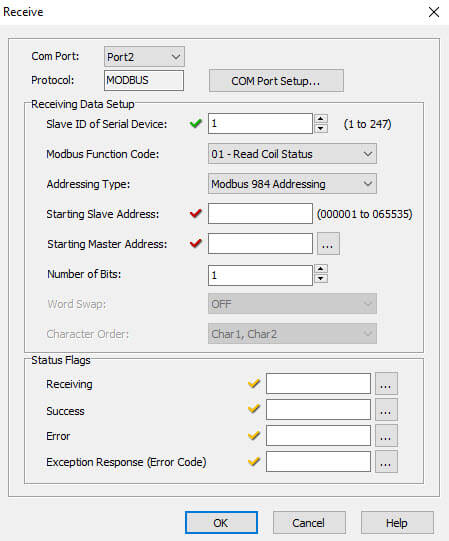

Receive

The Receive Instruction accepts Modbus or ASCII communications to your ladder program.

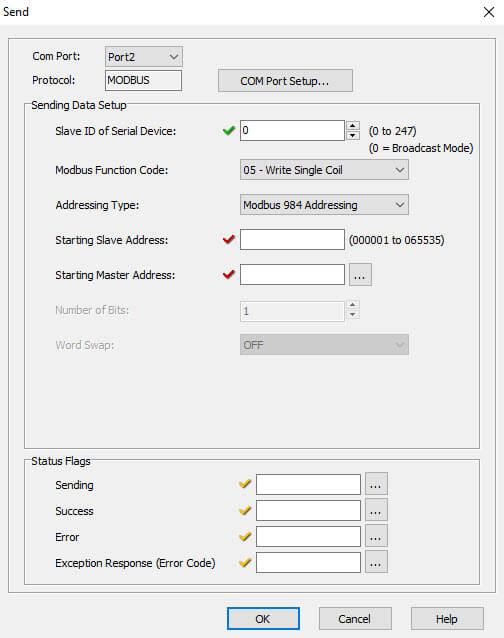

Send

The Send Instruction allows your ladder program to send Modbus or ASCII communications to other devices.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Check out our job openings

Free Online PLC Training

FREE Video Tutorials

FREE e-Newsletter

Automation Notebook

Product Literature

White Papers

News, Product and Training Bulletins

E-Books

Safe &

Secure

Safe &

Secure

We accept VISA, MasterCard, Discover, American Express, PayPal or company purchase orders.

Voted #1 mid-sized employer in Atlanta

Check out our

job openings