Cookies are not enabled on your browser.

Cookies are not enabled on your browser.Cookies are required for our site. Please enable cookies in your browser preferences to continue.

- Barcode / RFID / Vision

- Bulk Wire & Cable

- Cables (Terminated)

- Circuit Protection / Fuses / Disconnects

- Communications

- Drives & Soft Starters

- Enclosure Thermal Management & Lights

- Enclosures & Racks

- Field I/O

- HMI (Human Machine Interface)

- Hydraulic Components

- Motion Control

- Motor Controls

- Motors

- Pneumatic Components

- Power Products (Electrical)

- Power Transmission (Mechanical)

- Process Control & Measurement

- Programmable Controllers

- Pushbuttons / Switches / Indicators

- Relays / Timers

- Safety

- Sensors / Encoders

- Stacklights

- Structural Frames / Rails

- Tools & Test Equipment

- Valves

- Water (Potable) Components

- Wire & Cable Management

- Wire & Cable Termination

- Retired Products

Configuration Utilities

- PLC Family Selector

- P1000 PLC Systems

- P2000 PLC Systems

- P3000 PLC Systems

- ProductivityCODESYS

- CLICK PLC Systems

- Do-more® BRX PLC Systems

- LS-Electric® XGB PLC Systems

- Productivity®Open Systems

- Datalogic® Safety Light Curtains

- LS-Electric® Servo Systems

- Nitra® Pneumatic Grippers

- Object Detection (Sensors)

- PAL Controller Configurator

- Precision Gearbox Selector

- Protos X® Field I/O

- Pyrometers Selector

- Quadritalia® Modular Enclosures

- Stellar® Soft Starters

- Stepper System Selector

- SureFrame T-slot Extrusion

- SureMotion® XYZ Gantry

- SureServo2® System Selector

- SureStep® Linear Actuators

- Timing Belts & Pulleys

- Werma® Stacklights

- ZIPLinks

ProductivityOpen: Do I really need industrial ratings?

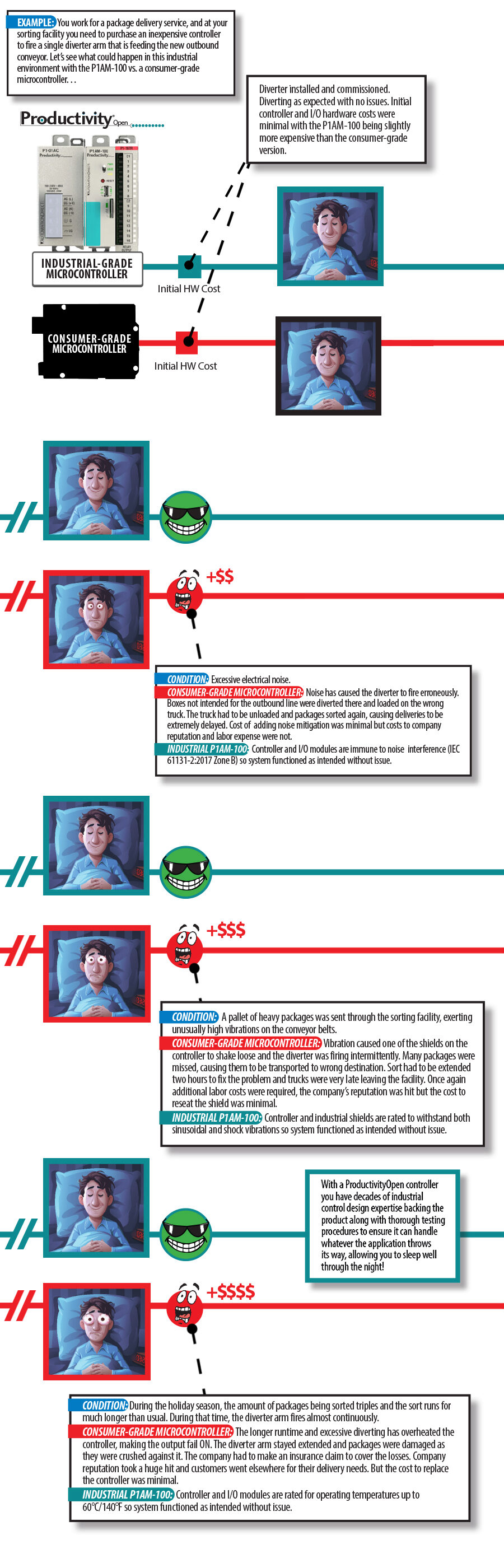

Don't take chances with maintenance costs

The cost of maintenance can quickly destroy your investment returns and your sleep!

When it comes to using a consumer-grade single-board microcontroller in an industrial environment, some say "So what if it breaks, I'll just replace it with another inexpensive microcontroller." While that may be an option, adding to your maintenance costs is never a winning scenario.

It's believed that up to 20% of plant operating expense is maintenance related. That's a good chunk and planning ahead to add to that percentage isn't a good idea. Besides the cost of replacement parts and the labor needed, you'll also have to consider the possibility of pulling valuable resources away from other projects, the increased probability of a failure during peak production hours, having to keep a large inventory of replacement parts on hand, and if any domino affect will occur from the failure - meaning how will the machine/system react and will other components fail as a result?

When you look at the big picture, it's apparent that the "I'll just swap it when it breaks" method can turn out to be quite costly. And although a consumer-grade microcontroller's initial cost is very attractive, the savings in maintenance and downtime that you get with an industrial microcontroller blows the initial $30-or-so price difference out of the water!

Check out our job openings

Free Online PLC Training

FREE Video Tutorials

FREE e-Newsletter

Automation Notebook

Product Literature

White Papers

News, Product and Training Bulletins

E-Books

Safe &

Secure

Safe &

Secure

We accept VISA, MasterCard, Discover, American Express, PayPal or company purchase orders.

Voted #1 mid-sized employer in Atlanta

Check out our

job openings

Loading...

Loading...