Cookies are not enabled on your browser.

Cookies are not enabled on your browser.Cookies are required for our site. Please enable cookies in your browser preferences to continue.

- Barcode / RFID / Vision

- Bulk Wire & Cable

- Cables (Terminated)

- Circuit Protection / Fuses / Disconnects

- Communications

- Drives & Soft Starters

- Enclosure Thermal Management & Lights

- Enclosures & Racks

- Field I/O

- HMI (Human Machine Interface)

- Hydraulic Components

- Motion Control

- Motor Controls

- Motors

- Pneumatic Components

- Power Products (Electrical)

- Power Transmission (Mechanical)

- Process Control & Measurement

- Programmable Controllers

- Pushbuttons / Switches / Indicators

- Relays / Timers

- Safety

- Sensors / Encoders

- Stacklights

- Structural Frames / Rails

- Tools & Test Equipment

- Valves

- Water (Potable) Components

- Wiring Solutions

- Retired Products

- Programmable Logic Controllers

- Productivity1000 PLCs

- Productivity2000 PLCs

- Productivity3000 PLCs

- ProductivityCODESYS

- LS Electric XGB Series PLCs

- ProductivityOpen

- CLICK PLCs

-

Do-more H2 PLCs or

Do-more T1H Series - Do-more BRX PLCs

- C-more Touch Panels

- AC & DC Drives

- Motion Control Components

- Servos

- StrideLinx

- Pneumatics

Configuration Utilities

- PLC Family Selector

- P1000 PLC Systems

- P2000 PLC Systems

- P3000 PLC Systems

- ProductivityCODESYS

- CLICK PLC Systems

- Do-more® BRX PLC Systems

- LS-Electric® XGB PLC Systems

- Productivity®Open Systems

- AC Motors

- Datalogic® Safety Light Curtains

- LS-Electric® Servo Systems

- Nitra® Pneumatic Grippers

- Object Detection (Sensors)

- PAL Controller Configurator

- Precision Gearbox Selector

- Protos X® Field I/O

- Quadritalia® Modular Enclosures

- Stellar® Soft Starters

- Stepper System Selector

- SureFrame T-slot Extrusion

- SureMotion® XYZ Gantry

- SureServo2® System Selector

- SureStep® Linear Actuators

- Timing Belts & Pulleys

- Werma® Stacklights

- ZIPLinks

How to choose a general purpose motor vs. an inverter-duty motor

General purpose motors have been around for many years. They are the workhorse of almost every industry. An inverter-duty motor is a much newer

concept that became necessary as motors began to be driven by VFDs (inverters or AC drives). An inverter duty motor can withstand the higher voltage

spikes produced by all VFDs (amplified at longer cable lengths) and can run at very slow speeds without overheating. This performance comes at a

cost: inverter-duty motors can be much more expensive than general purpose motors. Guidelines for choosing an Ironhorse general purpose motor vs. an

inverter-duty motor are given below. If your application falls within the guidelines below, there is no need to apply an inverter-duty motor.

NOTE: Inverter-duty motors have limitations as well. Please review the appropriate motor specifications for more details.

Background: AC motors can be driven by across-the-line contactors and starters. The electricity sent to the motor is a very clean (true) sine

wave at 60Hz. Noise and voltage peaks are relatively small. However, there are drawbacks: the motors can only run electrically at one speed (speed

reduction is usually handled by gearboxes or some other, usually inefficient, mechanical means) and the inrush of electrical current (when the motor

is first turned on) is usually 5 to 6 times the normal current that the motor consumes. The speed reduction apparatus is expensive and bulky, and the

inrush can wreak havoc with power systems and loading (imagine an air conditioning system in an old house - when the compressor kicks on, the lights

dim; now imagine the same circumstances with a motor the size of a small car).

Note: The following discussion applies only to 3-phase motors.

Enter the VFDs (variable frequency drives):

Drives were introduced to allow the speed of these motors to be changed while running and to lessen the inrush current when the motor first starts

up. To do this, the drive takes the incoming 60Hz AC power and rectifies it to a DC voltage. Every drive has a DC bus that is around 1.414 (sqrt of

2) * incoming AC Line Voltage.

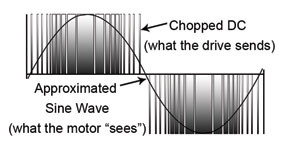

This DC voltage is then "chopped" by power transistors at very high frequencies to simulate a sine wave that is sent to

the motor. By converting the incoming power to DC and then reconverting it to AC, the drive can vary its output voltage and output frequency, thus

varying the speed of a motor. Everything sounds great, right? We get to control the frequency and voltage going out to the motor, thus controlling

its speed.

This DC voltage is then "chopped" by power transistors at very high frequencies to simulate a sine wave that is sent to

the motor. By converting the incoming power to DC and then reconverting it to AC, the drive can vary its output voltage and output frequency, thus

varying the speed of a motor. Everything sounds great, right? We get to control the frequency and voltage going out to the motor, thus controlling

its speed.

Some things to watch out for:

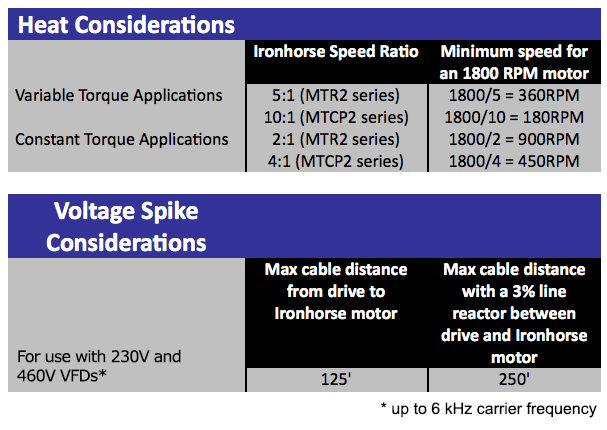

A VFD-driven general purpose motor can overheat if it is run too slowly. (Motors can get hot if they're run slower than their rated speed.)

Since most general purpose motors cool themselves with shaft-mounted fans, slow speeds mean less cooling. If the motor overheats, bearing and

insulation life will be reduced. Therefore there are minimum speed requirements for all motors.

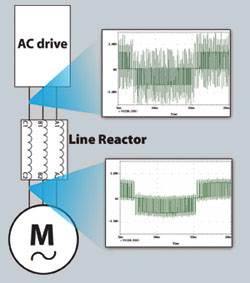

The voltage "chopping" that occurs

in the drive actually sends high-voltage spikes (at the DC bus level) down the wire to the motor. If the system contains long cabling, there

are actually instances where a reflected wave occurs at the motor. The reflected wave can effectively double the voltage on the wire. This

can lead to premature failure of the motor insulation. Long cable lengths between the motor and drive increase the harmful effects of the

reflected wave, as do high chopping frequencies (listed in drive manuals as carrier frequencies). Line reactors, 1:1 transformers placed at

the output of the drive, can help reduce the voltage spikes going from the drive to the motor. Line reactors are used in many instances when

the motor is located far from the drive.

In summary, general purpose motors can be run with drives in many applications; however inverter-duty motors are designed to handle much lower speeds

without overheating and they are capable of withstanding higher voltage spikes without their insulation failing. With the increased performance comes

an increase in cost. This additional cost can be worth it if you need greater performance.

Two important considerations for applying IronHorse motors with VFDs are given below.

Check out our job openings

Free Online PLC Training

FREE Video Tutorials

FREE e-Newsletter

Automation Notebook

Product Literature

White Papers

News, Product and Training Bulletins

E-Books

Safe &

Secure

Safe &

Secure

We accept VISA, MasterCard, Discover, American Express, PayPal or company purchase orders.

Voted #1 mid-sized employer in Atlanta

Check out our

job openings