Cookies are not enabled on your browser.

Cookies are not enabled on your browser.Cookies are required for our site. Please enable cookies in your browser preferences to continue.

- Barcode / RFID / Vision

- Bulk Wire & Cable

- Cables (Terminated)

- Circuit Protection / Fuses / Disconnects

- Communications

- Drives & Soft Starters

- Enclosure Thermal Management & Lights

- Enclosures & Racks

- Field I/O

- HMI (Human Machine Interface)

- Hydraulic Components

- Motion Control

- Motor Controls

- Motors

- Pneumatic Components

- Power Products (Electrical)

- Power Transmission (Mechanical)

- Process Control & Measurement

- Programmable Controllers

- Pushbuttons / Switches / Indicators

- Relays / Timers

- Safety

- Sensors / Encoders

- Stacklights

- Structural Frames / Rails

- Tools & Test Equipment

- Valves

- Water (Potable) Components

- Wire & Cable Management

- Wire & Cable Termination

- Retired Products

Configuration Utilities

- PLC Family Selector

- P1000 PLC Systems

- P2000 PLC Systems

- P3000 PLC Systems

- ProductivityCODESYS

- CLICK PLC Systems

- Do-more® BRX PLC Systems

- LS-Electric® XGB PLC Systems

- Productivity®Open Systems

- Datalogic® Safety Light Curtains

- LS-Electric® Servo Systems

- Nitra® Pneumatic Grippers

- Object Detection (Sensors)

- PAL Controller Configurator

- Precision Gearbox Selector

- Protos X® Field I/O

- Pyrometers Selector

- Quadritalia® Modular Enclosures

- Stellar® Soft Starters

- Stepper System Selector

- SureFrame T-slot Extrusion

- SureMotion® XYZ Gantry

- SureServo2® System Selector

- SureStep® Linear Actuators

- Timing Belts & Pulleys

- Werma® Stacklights

- ZIPLinks

Field I/O (or distributed I/O) can greatly improve system efficiency and reduce wiring costs where end devices are located at a distance, which result in easier installations and faster troubleshooting.

This page will refresh momentarily.

Warning

Some of the selected facets have been selected by the {{ assistanceData.title }} Help.

Resetting/clearing ALL facets will end {{ assistanceData.title }} Help.

![Help icon]() Selection Assistance - {{ assistanceData.title }}

Selection Assistance - {{ assistanceData.title }}

Stride Interactive Product Tour Request

IO-Link

Protos X I/O

Stride I/O

NITRA PAL I/O

LS Electric XGB

Terminator I/O

Point to Point Wireless I/O

Field I/O

Field I/O systems are available in a variety of form factors and protocol compatibility, most typically Modbus (RTU or TCP) and EtherNet/IP. IO-Link is a newer and very popular field I/O system that incorporates extended diagnostic information from IO-Link compatible sensors/actuators with standard I/O signals. Extremely fast and reliable EtherCAT communication is also supported by select LS Electric XGB bus couplers and the Murrelektronik Premium EtherCAT IO-Link master module.

For part listing and specifications, go to Shop Now

IO-Link

IO-Link allows field I/O devices to connect to an IO-Link master module, which creates a more effective field I/O system that provides real-time process values and control signals, while adding the functionality of collecting data such as condition, parameters, and performance from intelligent field devices.

- IO-Link masters handle field I/O signals (e.g., temperature, pressure, etc.) and diagnostic data such as sensor/actuator errors and health of connected IO-Link devices

- IO-Link masters have a built-in web server to view device status, configurations, and diagnostics

- IO-Link masters with screen interface allow IP, subnet mask, and gateway configurations

- IO-Link master options convert IO-Link signals to/from EtherCAT, EtherNet/IP, OPC-UA, and/or MQTT

- IO-Link hubs available to connect discrete digital and analog sensors/actuators to an IO-Link master

- Other IO-Link capable devices include sensors, pushbutton switches, signaling devices/towers, identification products, and communication modules

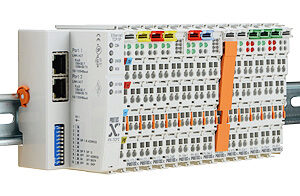

Protos X I/O

The Protos X compact, modular field I/O system allows a user to monitor and control remote field I/O devices without having to invest in another controller. The easy-to-install design saves time and excess field wiring and speeds up troubleshooting.

- The ultra-compact design makes it perfect for applications where a typical PLC or I/O solution simply would not fit

- Unique interlocking design of the terminals means the data and power buses are carried from module to module and used only when needed

- Four bus coupler models support Modbus RTU, Modbus TCP and EtherNet/IP protocols

Stride I/O

The Stride Field I/O family of modules provides a simple and economical means to connect inputs and outputs to a Modbus TCP communications network. Each module operates as a standalone Modbus TCP server, and can be configured via a built-in web server.

- Interfaces remote I/O points to a Modbus TCP network via Ethernet 10/100 Base-T

- Digital inputs, discrete relay and transistor outputs

- Analog current, voltage, resistance and temperature inputs; analog current and voltage outputs

NITRA PAL I/O

The NITRA Pneumatic Automation Link (PAL) system is an electro-pneumatic system as well as a field I/O system that can include electrical I/O or pneumatic valves or both. A system can be controlled either by an EtherNet/IP master or direct wiring (for configurations with exclusively pneumatic valves).

- Supports up to 16 discrete input and 16 discrete output modules per system, plus 4 analog output, and 4 analog temperature

- IP65 rated, machine mountable system decreases design and installation time

- Quick-disconnect electrical and push-to-connect pneumatic connections keep installation clean and simple

- Local expansion allows for several subsystems controlled from one EtherNet/IP node

LS Electric XGB

LS Electric has been in the PLC and I/O business for decades and is well known for reliable control solutions. Their bus coupler and I/O options are an excellent choice for most field I/O needs.

Depending on the model chosen, these bus couplers can communicate with any EtherNet/IP, Modbus TCP or EtherCAT master and allows I/O connections to be installed near the system being controlled. Save time and money by using remote I/O bus couplers and one single Ethernet cable run from the master device instead of multiple wire runs for each I/O point.

One bus coupler can support up to 8 LS XGB PLC I/O modules including high-density 32-point discrete modules. The module features two 100/1000 Mbps RJ45 Ethernet ports for extremely fast real-time communication.

Terminator I/O

Terminator Field I/O combines I/O points with their field terminations into a modular package to save panel space and money. With Terminator I/O, you can use distributed I/O nodes close to field devices for faster and more efficient wiring and troubleshooting.

- Network interface modules support Ethernet, DeviceNET, MODBUS remote I/O; some adapters include an on-board RS232 serial port

- Discrete and analog industrial I/O modules with modular terminal bases

- Configuration flexibility by plugging together a network interface module with up to 16 I/O modules

- For high power systems, combine multiple power supplies on a single I/O set

Point to Point Wireless I/O

Point-to-point wireless I/O is ideal for industrial settings where wiring is impractical, such as long distances, physical obstacles, or moving equipment. It creates a dedicated, bidirectional radio link between a pre-paired set, enabling reliable transmission of analog or digital signals with easy deployment.

Check out our job openings

Free Online PLC Training

FREE Video Tutorials

FREE e-Newsletter

Automation Notebook

Product Literature

White Papers

News, Product and Training Bulletins

E-Books

Safe &

Secure

Safe &

Secure

We accept VISA, MasterCard, Discover, American Express, PayPal or company purchase orders.

Voted #1 mid-sized employer in Atlanta

Check out our

job openings

Loading...

Loading...