Cookies are not enabled on your browser.

Cookies are not enabled on your browser.Cookies are required for our site. Please enable cookies in your browser preferences to continue.

- Barcode / RFID / Vision

- Bulk Wire & Cable

- Cables (Terminated)

- Circuit Protection / Fuses / Disconnects

- Communications

- Drives & Soft Starters

- Enclosure Thermal Management & Lights

- Enclosures & Racks

- Field I/O

- HMI (Human Machine Interface)

- Hydraulic Components

- Motion Control

- Motor Controls

- Motors

- Pneumatic Components

- Power Products (Electrical)

- Power Transmission (Mechanical)

- Process Control & Measurement

- Programmable Controllers

- Pushbuttons / Switches / Indicators

- Relays / Timers

- Safety

- Sensors / Encoders

- Stacklights

- Structural Frames / Rails

- Tools & Test Equipment

- Valves

- Water (Potable) Components

- Wiring Solutions

- Retired Products

- Programmable Logic Controllers

- Productivity1000 PLCs

- Productivity2000 PLCs

- Productivity3000 PLCs

- ProductivityCODESYS

- LS Electric XGB Series PLCs

- ProductivityOpen

- CLICK PLCs

-

Do-more H2 PLCs or

Do-more T1H Series - Do-more BRX PLCs

- C-more Touch Panels

- AC & DC Drives

- Motion Control Components

- Servos

- StrideLinx

- Pneumatics

Configuration Utilities

- PLC Family Selector

- P1000 PLC Systems

- P2000 PLC Systems

- P3000 PLC Systems

- ProductivityCODESYS

- CLICK PLC Systems

- Do-more® BRX PLC Systems

- LS-Electric® XGB PLC Systems

- Productivity®Open Systems

- AC Motors

- Datalogic® Safety Light Curtains

- LS-Electric® Servo Systems

- Nitra® Pneumatic Grippers

- Object Detection (Sensors)

- PAL Controller Configurator

- Precision Gearbox Selector

- Protos X® Field I/O

- Quadritalia® Modular Enclosures

- Stellar® Soft Starters

- Stepper System Selector

- SureFrame T-slot Extrusion

- SureMotion® XYZ Gantry

- SureServo2® System Selector

- SureStep® Linear Actuators

- Timing Belts & Pulleys

- Werma® Stacklights

- ZIPLinks

IMPORTANT NOTICE: Using a newer version of Productivity Suite to save or download a project created with a previous version may alter the project and its functionality. Making backup copies of existing projects is highly recommended.

What's New In Productivity Suite V4.1

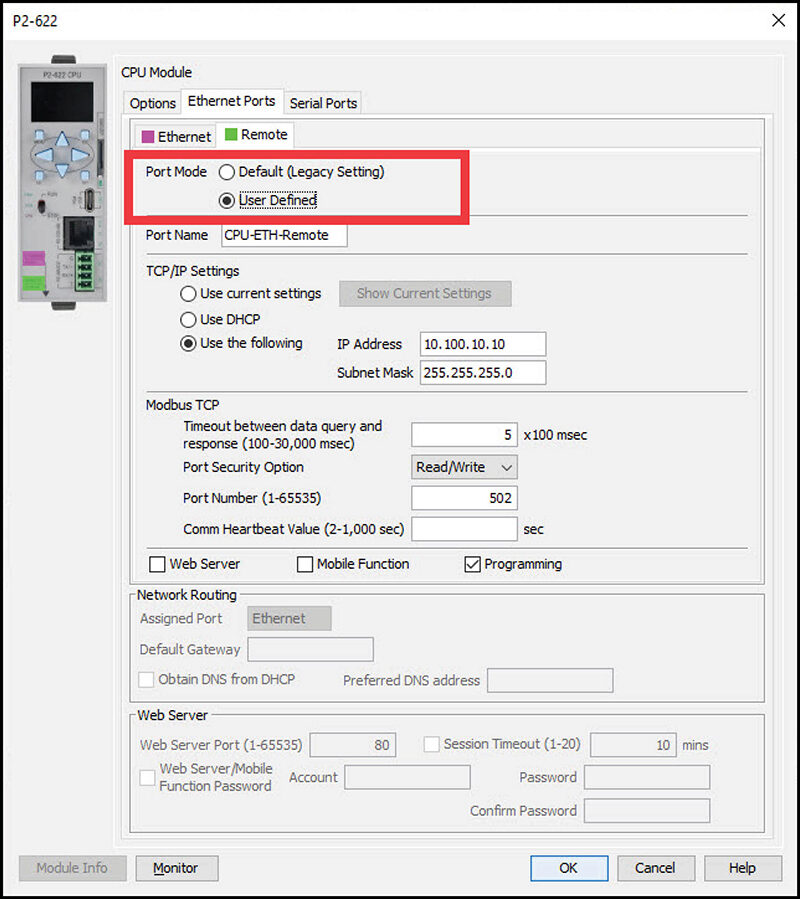

- Port 2 open Port 2 on the P2-622 CPU can now be configured as an additional multipurpose Ethernet port (normally reserved for remote I/O).

- MQTTS support (P2-622 only)

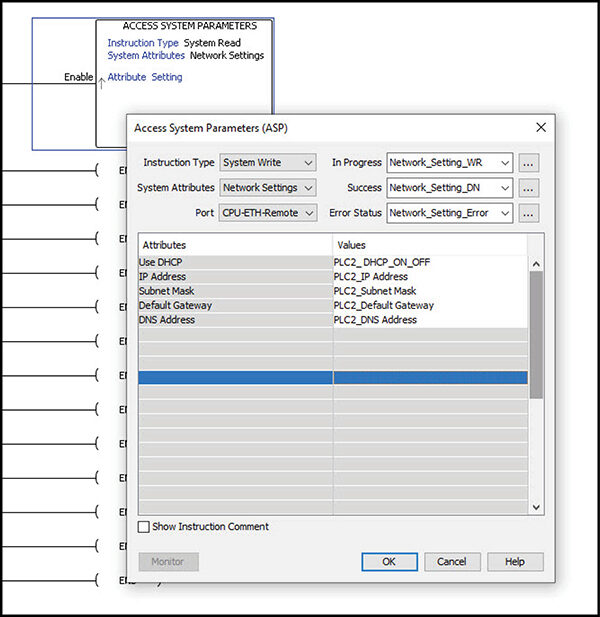

- New ASP instruction allows P2-622 CPU communication port configuration changes from within the ladder code.

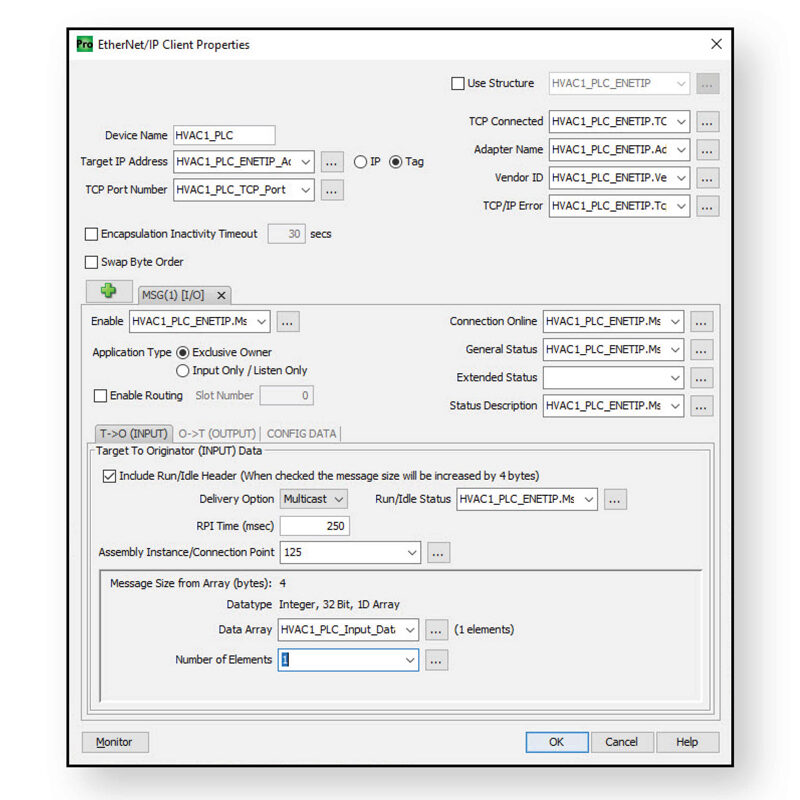

- The new Variable Communications Instructions (VCIs) allow tags to be used for almost every field so you can communicate with virtually unlimited devices using a single instruction.

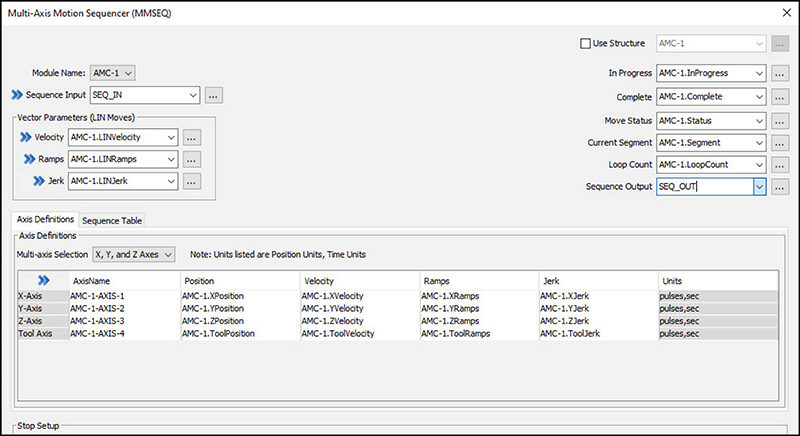

- The new Multi-Axis Motion Sequencer instruction allows you to:

- Perform smooth movements between two or more points in up to 3 axes, plus an optional tool axis.

- Easily code For/Next or Do/While loops to repeat portions of the sequence, as desired.

- Iterate through up to 64 steps in a motion sequence, including adding timers and pauses between move actions.

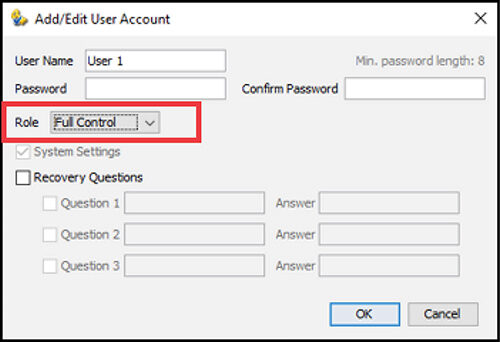

- Enhanced access control - New user roles allow you to control who has access to the project file and what they can do with it. Full control, full monitor, limited monitor, and read only are some of the roles available and they can be easily set from the User Account dialog.

What's New In Productivity Suite V3.11

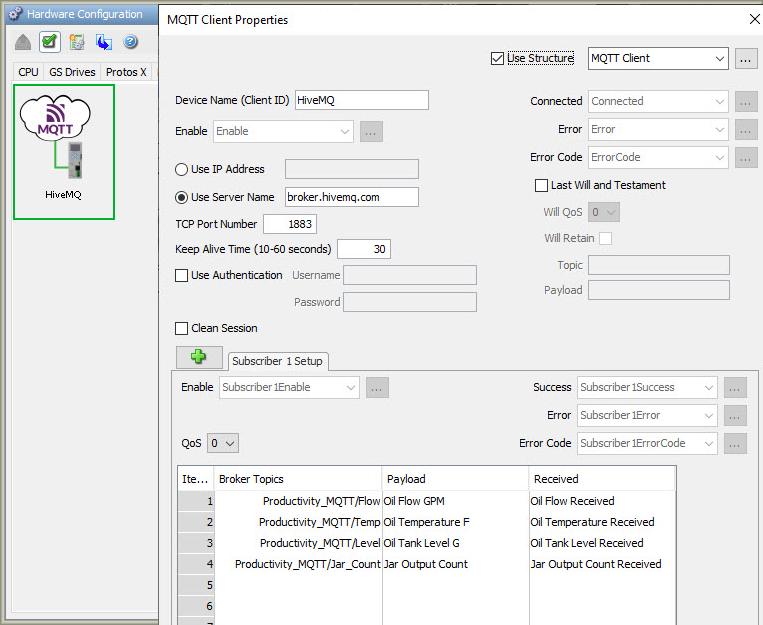

- Added support for MQTT communication

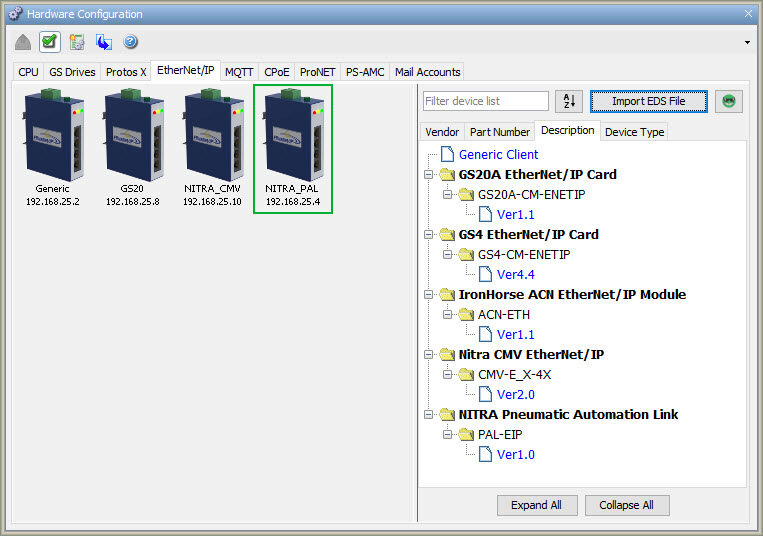

- EDS file library added for a convenient way to organize and sort EDS files

What's new in Productivity Suite V3.10

- Added support for the PS-AMC motion controllers

- Added support for GS-20 AC drives

- Added support for P1-RX remote I/O module

- Added parameter enumeration support for EtherNet/IP EDS file import.

- Improve navigating through the EtherNet/IP connections list.

- EtherNet/IP: Improvements made to the evaluation and usage of Socket Address info within the Forward_Open response.

- Add and Edit connection dialog change StrideLinx connection label to "Remote/User Defined"

- Structures and Arrays with Data View Graphing - now allowing right-click on an Array Element or Structure Element and add it to the graph

What's New in Productivity Suite V3.9

- Added EtherNet/IP and CPoE (custom protocol over Ethernet) support to the PLC Simulator

- Added selectable time base to the Simple Timer Instruction (STMR)

- New "Default to retentive when creating new tags" checkbox added to Tools>Option>TagDB

- New "Include System Information" checkbox added to Create System Report dialog

- Added Input Only/Listen Only support to EtherNet/IP I/O message configuration

- Added Input Only/Listen Only support to EDS file import

What's new in Productivity Suite V3.8

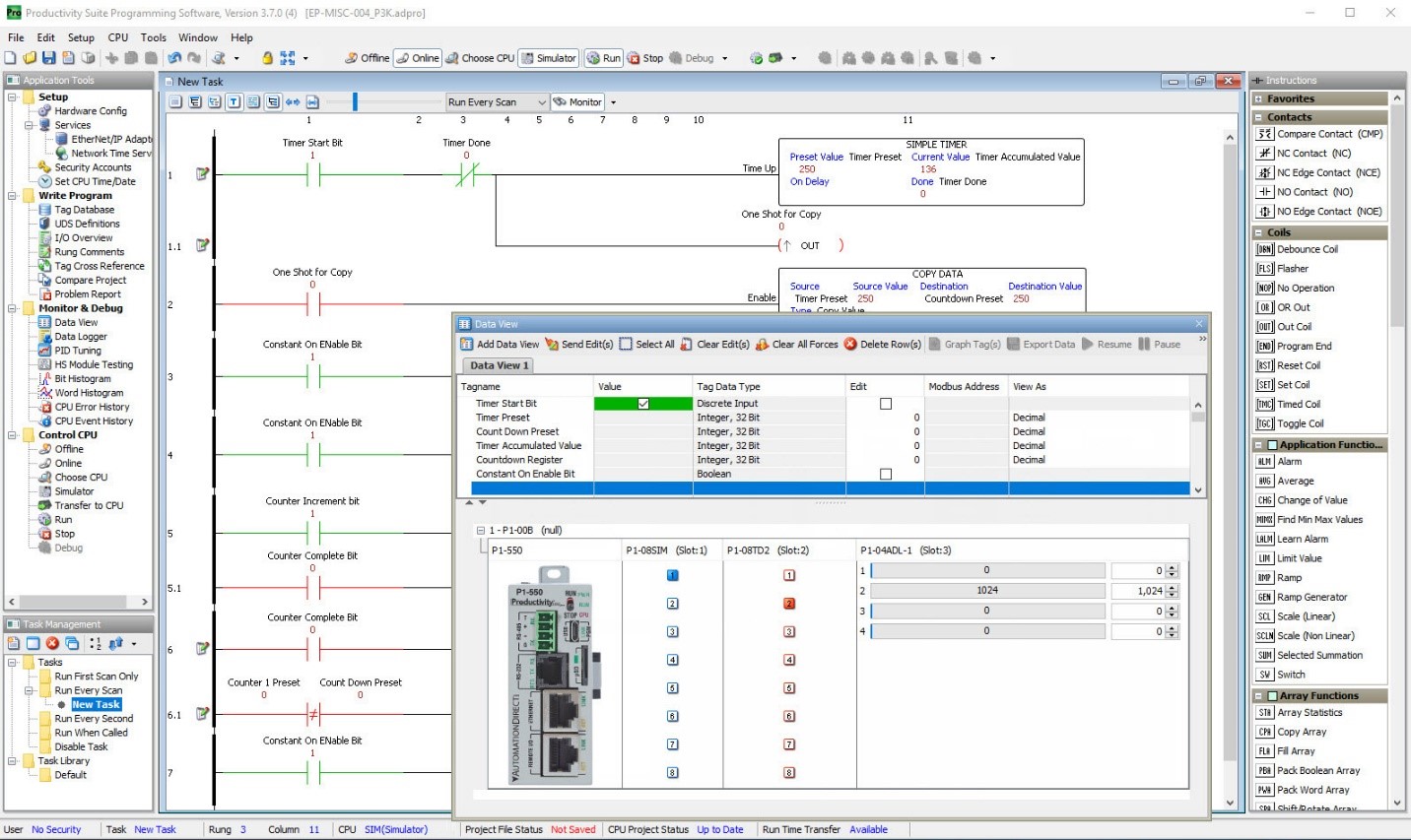

New PLC simulator

The Productivity Suite Simulator provides a means to emulate parts of the Productivity Series hardware, including:

- Productivity1000 CPUs and local I/O stack, Productivity2000 and Productivity3000 CPUs and local bases

- All basic I/O modules, both analog and digital

- Modbus TCP server/client connections on external Ethernet port

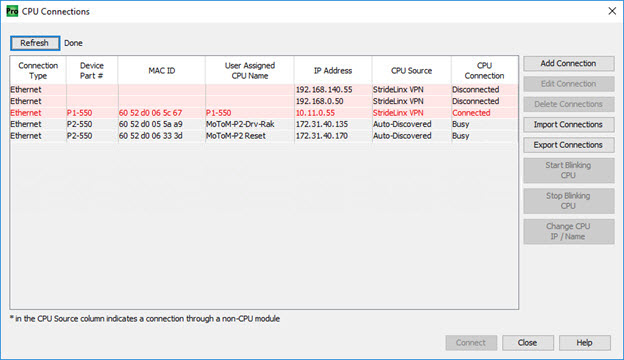

Added StrideLinx integration to CPU connections dialog

StrideLinx integration provides a secure connection to remote CPUs within Productivity Suite through a StrideLinx VPN Router. Once configured, Productivity CPUs connected through StrideLinx VPN routers are easily selectable from within the CPU Connections dialog.

What was new in Productivity Suite V3.7

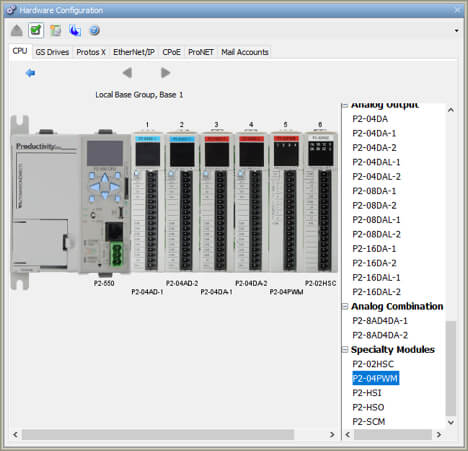

Support for the new Productivity2000 Modules has been added.

- P2-01DC Power Supply

- P2-02HSC High-speed Counter Module

- P2-04PWM Pulse Width Modulation Output Module

- P2-04AD-1, P2-04AD-2 Analog Input Modules

- P2-04DA-1, P2-04DA-2 Analog Output Modules

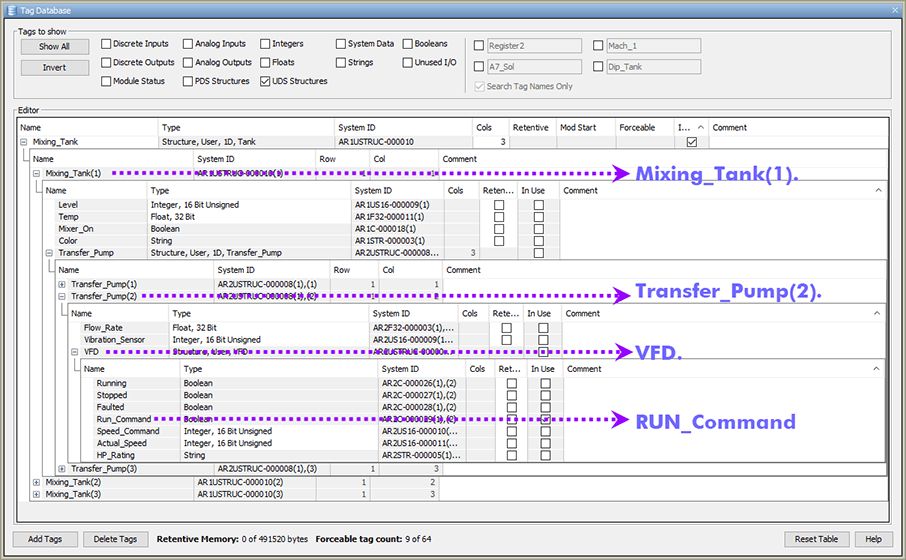

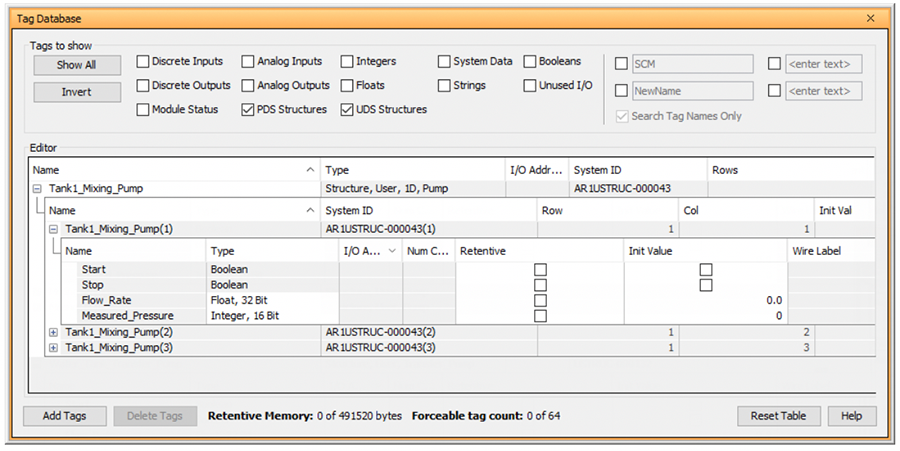

Advanced array support for User-Defined Structure (UDS) definitions

Ex. Tag = MixingTank(1).Transfer_Pump(2).VFD.Run_Command - contains two nested UDS arrays (Transfer_Pump and VFD) inside the Mixing_Tank UDS definition.

Other Improvements

- Added ability to designate an element of a UDS as retentive

- Added ability to designate string length of a String element in a UDS definition

What was new in Productivity Suite V3.6

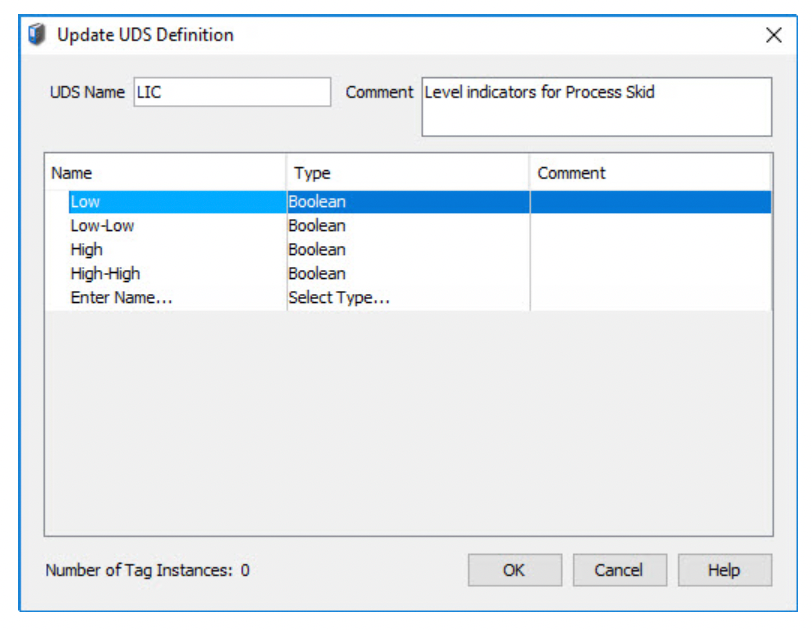

User Defined Structures

User Defined Structures (UDS) is a group of data types (BOOL, FLOAT, INT, pre-defined structures, etc.) which are defined by the user and re-used at will in the ladder code and/or fill-in-the-blank instructions.

1-dimensional UDS arrays are available for easy indexing through custom tag variables.

Other Improvements

- Updated CPD instruction (Added Structure support to the instruction)

- AutoTune from HMI (Modification to the PID instruction)

- Detect Ladder code below 'End'

- "Edit Instruction Tag" added to Ladder instructions right click menu

- Added Warnings to the Problem Report dialog. It now shows Errors and Warnings

- Various Changes to the Tag Database and Add Tags Dialogs

- New Help file format (HTML5)

What was new in Productivity Suite V3.5

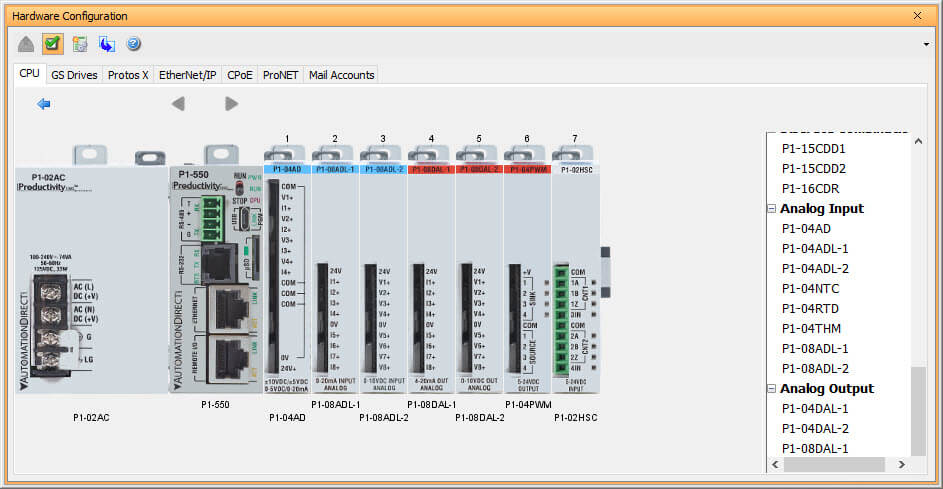

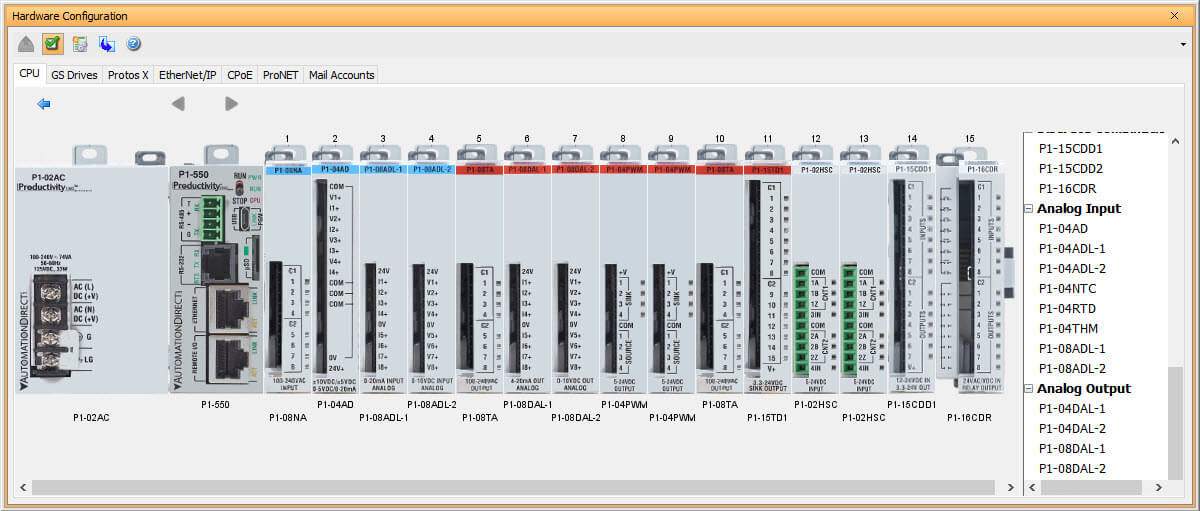

Support for the new Productivity1000 Modules has been added.

- P1-550 CPU

- P1-02AC Power Supply (allows for 15 expansion modules)

- P1-01DC Power Supply

- P1-02HSC High-speed Counter Module

- P1-04PWM Pulse Width Modulation Output Module

- P1-04AD, P1-08ADL-1, P1-08ADL-2 Analog Input Modules

- P1-08DAL-1, P1-08DAL-2 Analog Output Modules

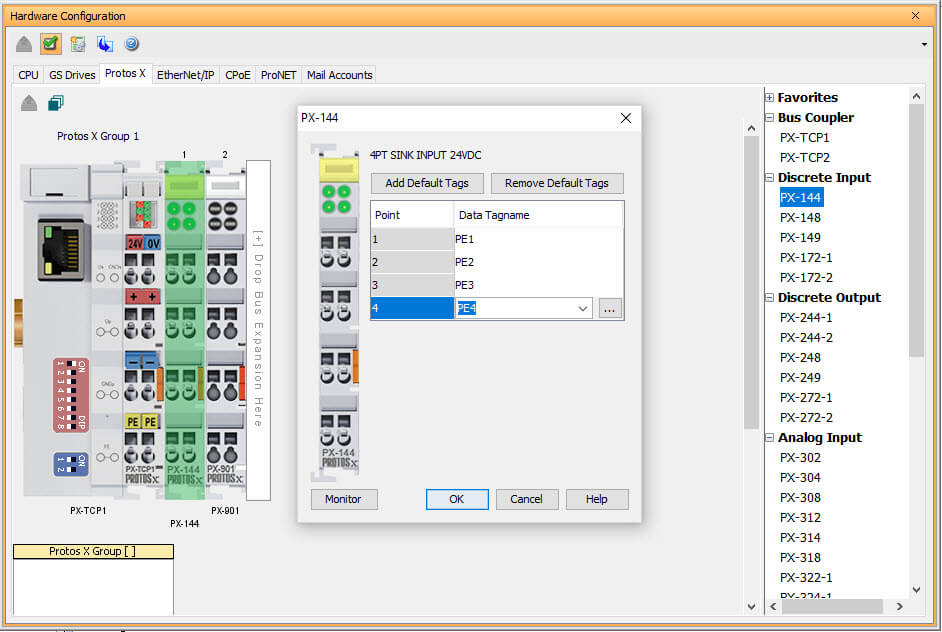

Integration of the Protos X Field I/O system to be used as remote I/O

Expanded support for up to 15 expansion I/O modules

What was new in Productivity Suite V3.4

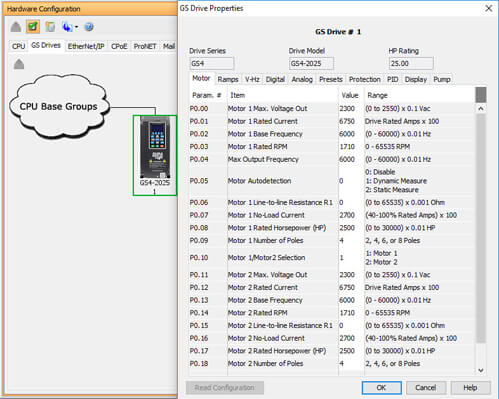

The new Durapulse GS4 parameters have been integrated into the Hardware Configuration.

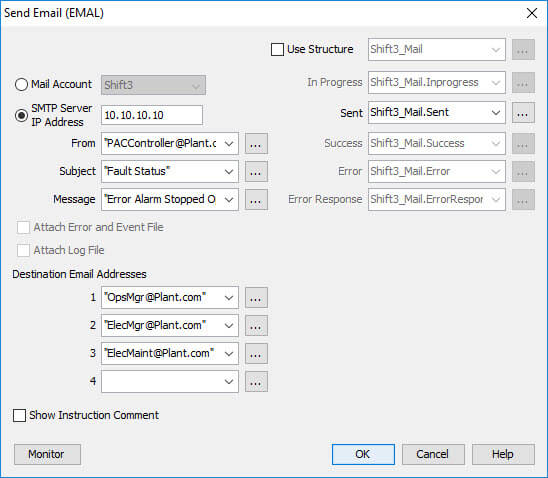

Pre-defined widgets for the most popular Mail Servers (Gmail, Aol, Outlook, Yahoo) have been added to be used with the updated Send Email instruction.

Updated Send Email instruction allows for secure emails (TLS) and allows data log attachments.

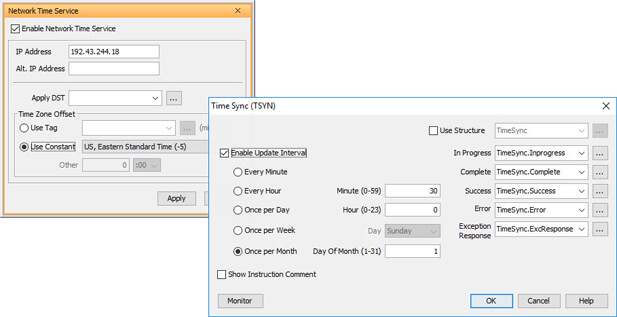

Network Time Service and Time Sync instruction have been added allowing the PLC's internal real-time clock

and calendar to sync with the date and time from a specified time server.

What was new in Productivity Suite V3.2

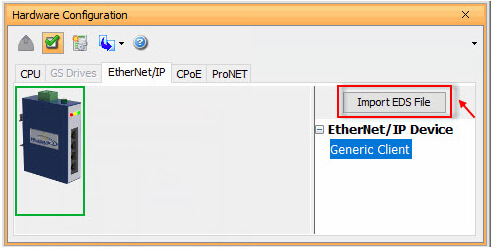

EtherNet/IP EDS File Import

•

Other Improvements

EtherNet/IP EDS File Import

Productivity Suite now supports Electronic Data Sheet (EDS) file imports for EtherNet/IP device and network configurations. These ASCII text files describe the features of an EtherNet/IP device and can easily be imported into the hardware configuration of your Productivity Suite project. Once imported, these EDS files are stored globally across software versions.

Other Improvements

- Any off screen panels that were set up on multiple screens are now automatically moved back if only one screen is detected.

- Add selection for case sensitive to TagDB compare.

- Project convert from P3 to P2 with EX modules updated to populate with P2-RS instead of deleting bases.

- Total Retentive Memory consumed and forcible tag count viewable at bottom of TagDB window.

- Added the ability to use ASCII extended character in documentation fields and tag names.

What was new in Productivity Suite V2.4

Productivity Network

•

Custom Protocol over Ethernet

•

Firmware Upgrade Progress Indicators

•

DataView Enhancements

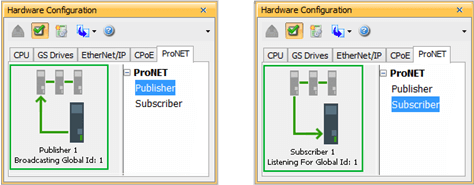

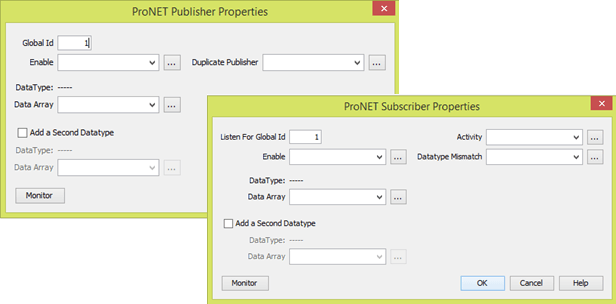

Productivity Network (ProNET)

The new Productivity Network (ProNET) feature adds the ability to share data, over Ethernet, with other Productivity Series CPU's quickly and easily.

ProNET uses the verbs 'publishing' and 'subscribing' to describe how one controller's data is exchanged with other controllers on the network. Publishing is analogous to sending data, and is done only if ProNET is configured to 'publish' one or more of its assigned tags. If so configured, the P-Series controller will broadcast a packet that contains the data from the selected tags. ProNET uses 1D arrays for storing data. There are a maximum of 32 publishers and/or subscribers can be defined (32 unique global identifiers available) on the data sharing network. A controller can be configured to publish 64-32 bit elements, 128-16 bit elements, or 256-8 bit or Boolean elements per publisher.

- Configure data sharing between P-Series CPU's using the Productivity Network (ProNET) properties setup screens accessable from the hardware configuration window.

- Each member of the ProNET data sharing network can receive data by subscribing to a network specified by a global identifier.

- Members can optionally "publish" data to the other nodes of the data sharing network, also by using these global identifiers.

- The ProNET configuration uses UDP broadcast packets to publish blocks of data to the network. The use of broadcast packets limits the scope of the shared data network to the local broadcast domain.

- The ProNET configuration works with 1D array tag(s) that can contain up to 65535 elements. There is a limit of 64 -32 bit elements, 128 -16 bit elements, or 256 -8 bit or Boolean elements of data per publisher or subscriber.

- A local array of tags is specified for the local storage of the data that is to be published and subscribed over the data-sharing network.

- When the enable input specified in the ProNET configuration is True, the data in the array will be published at a fixed rate of 10 times per second (every 100 msec.).

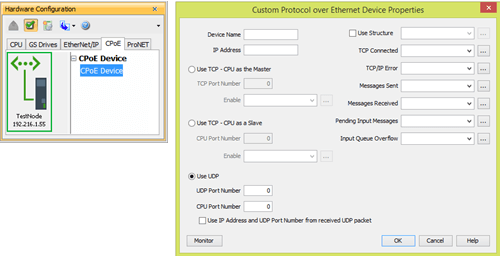

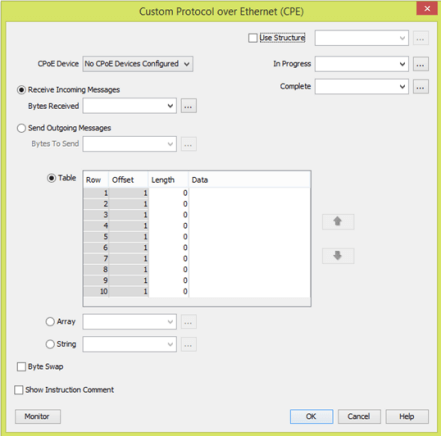

Custom Protocol over Ethernet (CPoE)

New Custom Protocol over Ethernet (CPoE) feature allows the ability to Send or Receive structured Hex-Based data to/from another device over Ethernet. This is particularly useful in situations where the Productivity series CPU must communicate with a device that has Hex-Based communications but does not support one of our standard protocols.

To configure your Custom Protocol over Ethernet Device, use the setup tools found in the Hardware Configuration window. The Custom Protocol over Ethernet options are found under the CPoE tab of the Hardware Configuration

Once the device is configured, use the Custom Protocol over Ethernet (CPE) instruction to Send or Receive structured Hex-Based data to/from another device over Ethernet.

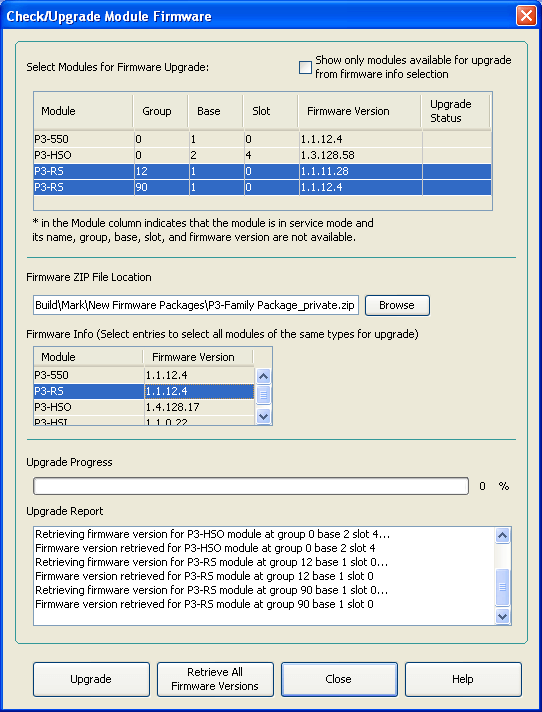

Firmware Upgrade Progress Indicators

Added Check marks to indicate each step is complete in Firmware upgrade window.

DataView Enhancements

Bit of Word elements can now be viewed in DataView by right clicking on a word and selecting "show bit of word details".

Also added the ability to show control characters, to show string values in Hex (separated by spaces), and to show string values in decimal (separated by spaces) for string tags in DataView.

What was new in Productivity Suite V2.3

Return from Called Task

•

Support for NEW MODULES!

Return from Called Task (RFCT)

New Instruction Return from Called Task (RFCT) used to Stop and immediately Exit from a Called Task

Support for NEW P2000 MODULES!

Added support for new P2000 modules: P2-04DAL-1, P2-04DAL-2, P2-08NAS, P2-08TAS, P2-08TD1S, P2-08TD2S, P2-15TD1, P2-15TD2, P2-32ND3, P2-32TD1P, P2-32TD2P.

What was new in Productivity Suite V2.0

Compare Project

•

Force from ladder

•

Project Conversion

•

New Stop mode transfer limits

•

Print to .PDF

•

Ladder less pixelated

•

Recent Projects

•

I/O view

•

Updated Instruction Panel

•

Updated Instruction Shortcut

•

Improvement to Printing

•

Drag-n-Drop Dataview into Graphing

•

Drag ladder instructions

•

Right Click Tag Search

Support for Productivity2000 Series contollers!

The Productivity Suite software now supports the Producitvity2000 PLC, the latest member of the Productivity family.

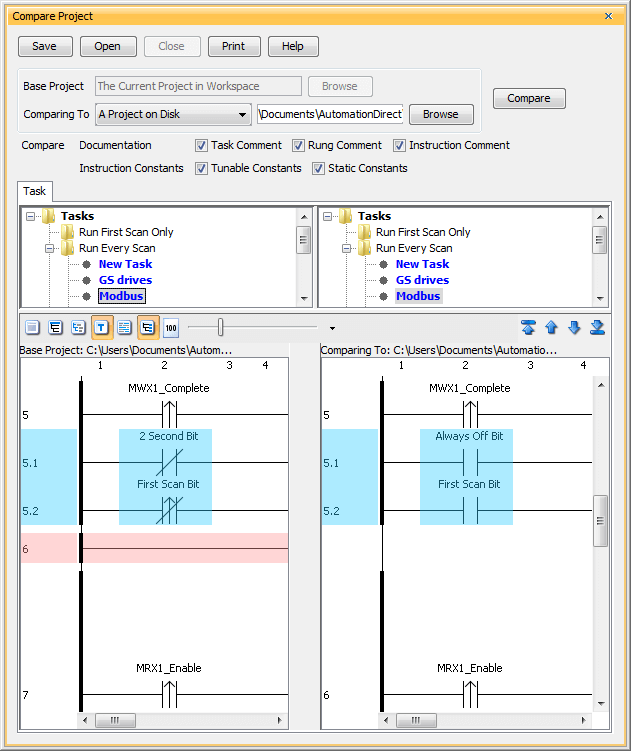

Compare Project

Compare Project allows users to select Productivity Series PLC project files (.adpro) and perform project-to-project comparisons on these files.

In addition, the Compare Project Tool provides you with a graphical representation of your ladder logic and the ability to apply filters to perform a selective Compare. Once the Compare Project Tool has performed the comparison, it generates a report detailing the differences between the two project files.

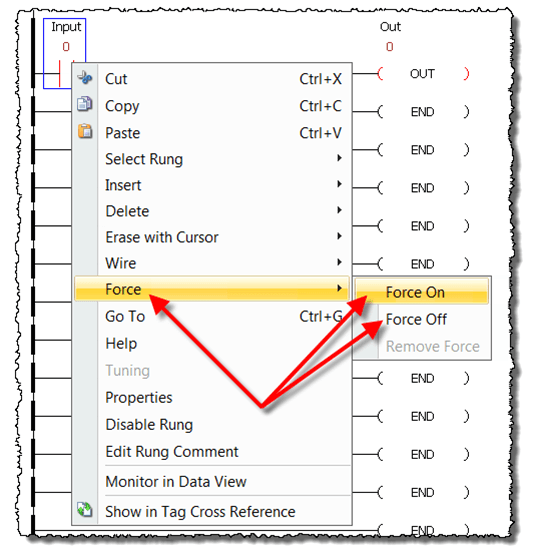

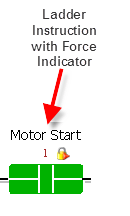

Force From Ladder

Right click on any tag in your ladder logic program to "force" any contact or coil in the ladder editor (without having to launch a Data View window). An icon now will be shown next to any contact or coils indicating if it is forced on or off.

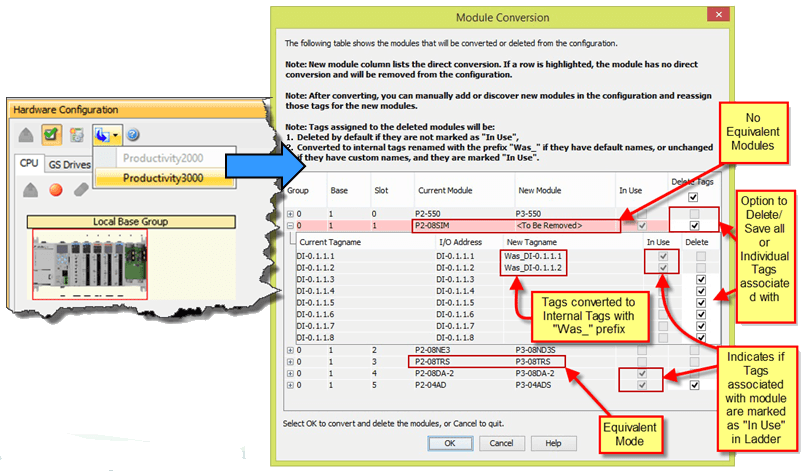

Project Conversion

Added the ability to easily convert a P3000 project to a P2000 project or vise-versa using integrated conversion utility.

New Stop mode transfer limits

Some changes to a project cannot be handled by a Run Time Transfer, and must be downloaded using a Stop Mode Transfer. Here are the editing changes that will force the user to perform a Stop Mode Transfer (new limits in bold):

- Any changes to the hardware configuration, such as:

- Adding or removing hardware

- Changing the configuration of a piece of hardware, Including:

- Ethernet or serial port configuration.

- Hot swap enable or disable on any module or base.

- Adding an EtherNet/IP device and any configured changes.

- Adding more than 5000 tags of any data type (Excluding Strings and Structures)

Note: This limit is additive between stop mode transfers. - Adding more than 50,000 characters or changing the length of a String data type Tags.

Note: This limit is additive between stop mode transfers. - Changes to Data Logger.

- Changes to Modbus Server settings under Project Properties.

- Changes to the buffer size for a FILI instruction.

- Adding more than 5,000 elements of a structure data type to TagDB.

Note: This limit is additive between stop mode transfers. - Enabling Bit of Word under Project Properties.

- Enabling Structures in under Project Properties.

- Enable and Disable of EtherNet/IP Adapter.

At any time, the availability of Run Time Transfer can be verified at the bottom of the Productivity Suite window.

Print to .PDF

Built in print to .pdf option added for printing both ladder and compare project features.

Ladder view is less pixelated when zoomed

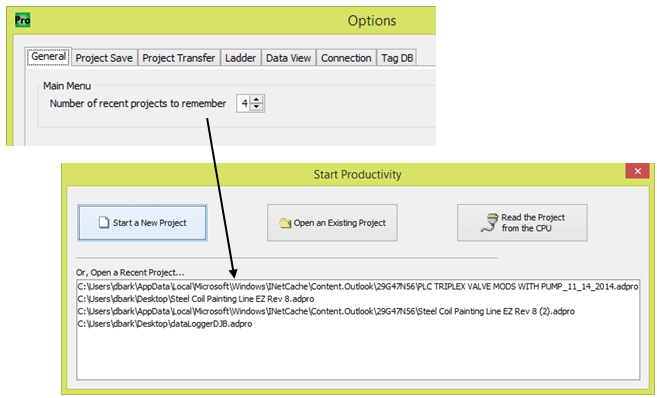

Recent Projects

A selectable number of your most recent projects can now be quickly accessed from the Start Productivity screen

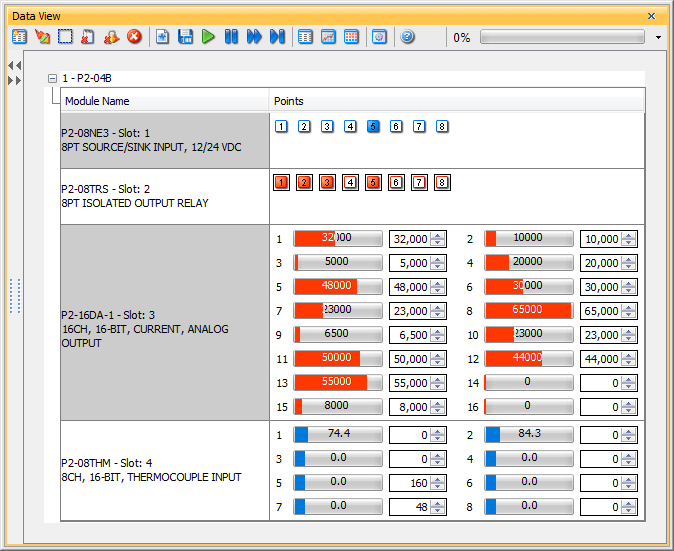

I/O view

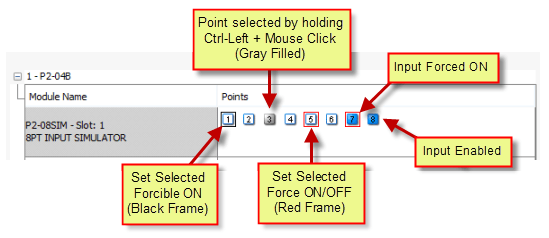

I/O View is a quick and easy way to monitor all hardware points installed in a system. A user can also force on or off any discrete or analog point using I/O View.

Analog channels display values numerically AND via a horizontal bar graph (color fill). Options for discrete I/O points include:

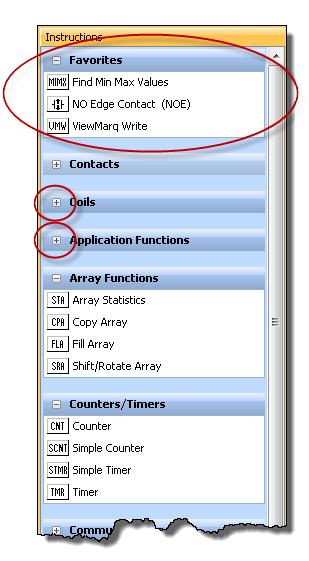

Updated Instruction Panel

Updated Instruction Panel has collapsible categories, including a new favorites category that allows a user to quickly add their Favorite instructions to this area for quicker access.

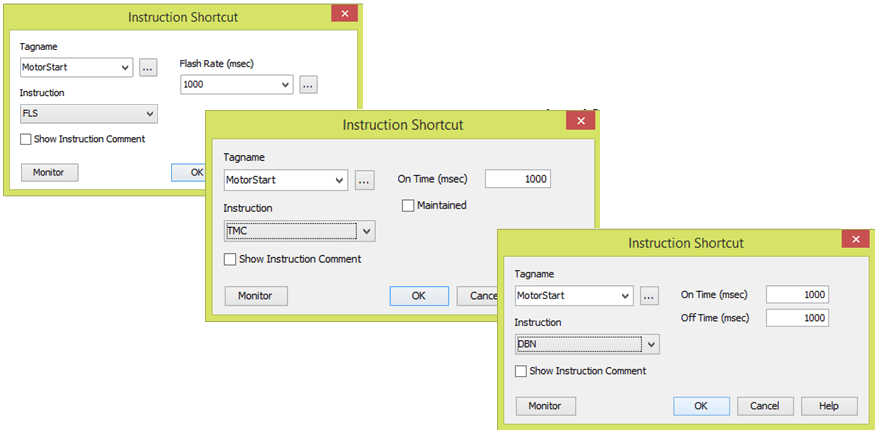

Updated Instruction Shortcut

Updated the Instruction Shortcut feature with a new look, and added FLS, DBN, & TMC instructions to the Instruction Shortcut. (Access the Instruction Shortcut by selecting a ladder loaction and typing a tagname. The Instruction Shortcut window will appear. You have the ability to choose from a list of instructions in the drop down of either contacts or coils to quickly add a new tag without having to enter the instruction first. This is one of several quick methods of entering tags and instructions into your ladder code.)

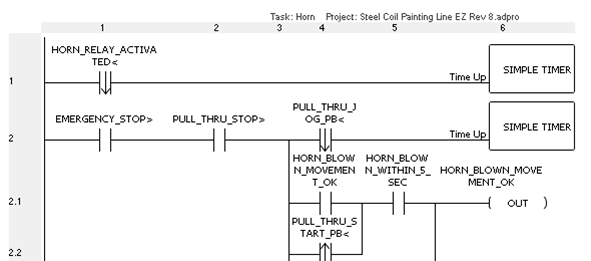

Improvements to Printing

Users now have the ability to select rung(s) in ladder, and right click to send directly to printer, or print the entire task. Added ability to Print, Save, & Copy the DataView Graphing window with the right click option, and added the ability to turn "block details" on or off for printing.

This screen capture shows the effect of turing off block details, the Simple Timer instructions details are not shown, and the resulting print-out is much more concise.

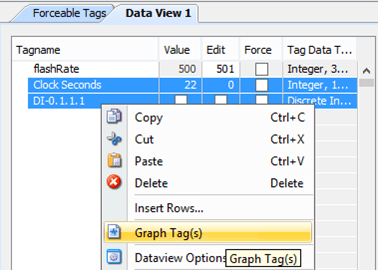

Drag & Drop Data View into Graphing

You can now left click & drag selected tag(s) from a Data View window to anywhere in the graphing window to begin graphing of the selected tags.

Or you can right click on selected tag(s) and select Graph Tags to begin graphing.

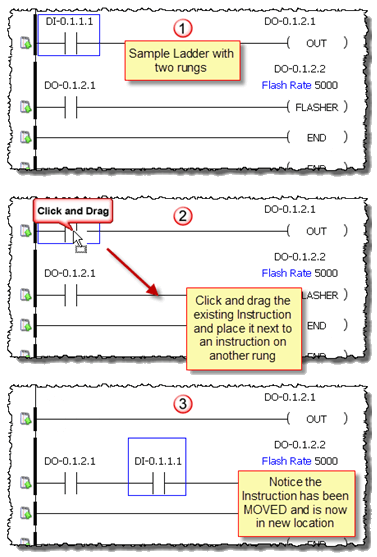

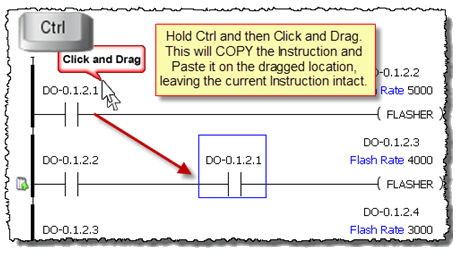

Drag & Drop Ladder Instructions

Move

Left click to drag an already placed instruction in ladder and drop it into another location in the same ladder window.

Copy

Press and hold the "Ctrl" key while dragging the Instruction, and a Copy of the selected Instruction will be made and dropped into the specified location in the ladder window.

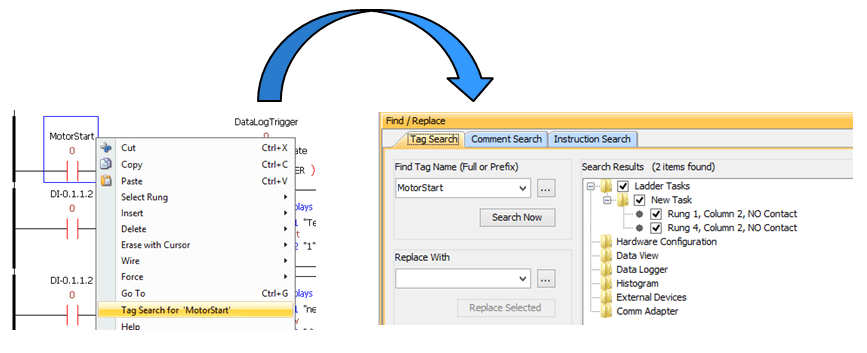

Right Click Tag Search

You can directly access the tag search feature of find/replace via Data View, TagDB, or ladder editor by right clicking to initiate a search for other occurences of that tag. Find Tag name is populated and search results done with one simple click.

What was new in Productivity Suite V1.10

Tag I/O Reassignment

•

Structure data types

•

EtherNet/IP

•

P3-SCM

•

Full Duplex

•

Binary Only Projects

•

Data View Graphing

•

Enhanced Tag Export

Tag I/O Reassignment:

Tag I/O Reassignment allows a user to create tag(s), at will, without knowing what initial or final I/O modules will be installed in the system. With Tag I/O Reassignment a user can create tags, then later reassign these tags to I/O points once the module configuration is setup in the Hardware Configuration.

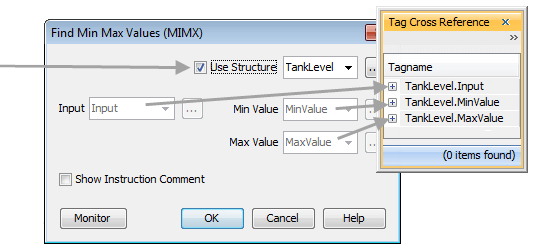

Structure data types:

Structure data types are specific sets of tags combined together for convenience. Using Structures in instructions can speed up program development because multiple tags are created and assigned automatically. Simply check the "Use Structure" box and enter the name for your structure. The Productivity Suite software does the rest, creating all the tags required for that instruction.

Default I/O tags:

If the "Default I/O tags" option is selected when modules are added to the system their default I/O tags are automatically assigned to each I/O point. With the option deselected when modules are added, none of the default I/O tags are assigned to the I/O points.

EtherNet/IP:

New Feature (P3-550 Only): Support for two types of EtherNet/IP messaging: IO Messaging and Explicit Messaging. IO Messaging is accomplished through a Class 1 Connection and Explicit Messaging can be accomplished through a Class 3 Connection or an Unconnected Message.

Support for the new P3-SCM Serial Communications Module:

Version 1.10 includes support for the new P3-SCM (Serial Communications Module) - The P3-SCM is a serial communications module capable of Modbus, ASCII, and Custom Communication Protocols and able to power the C-More Micro through RS-232 (Port 1 Only).

Full Duplex Support for RS 232 ports:

Full Duplex is now supported on all RS-232 ports in a Productivity3000 system (P3-550, P3-530, P3-RS, P3-RX, and P3-SCM Modules). Full Duplex allows the RS-232 serial ports to transmit and receive simultaneously.

Binary Only Projects:

OEMs can now load a “binary only” version of a project onto a Productivity PAC from a USB thumb drive. This prevents users from viewing/editing the ladder code should they connect with the Productivity Suite software. Nor is it possible to transfer these “binary only” files from the PAC to pen drive thus further protecting OEM source code.

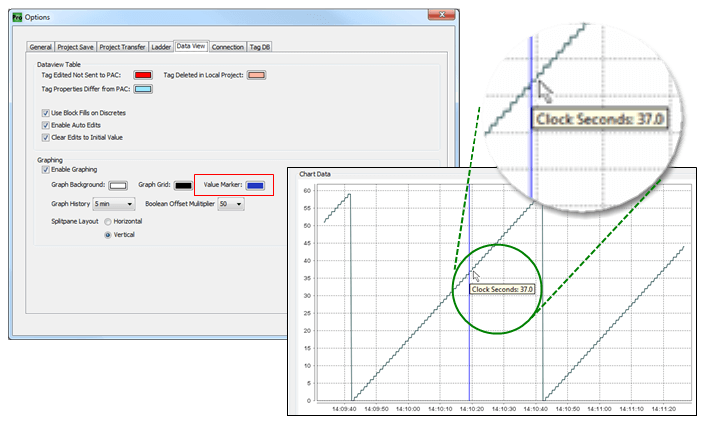

Data View Graphing:

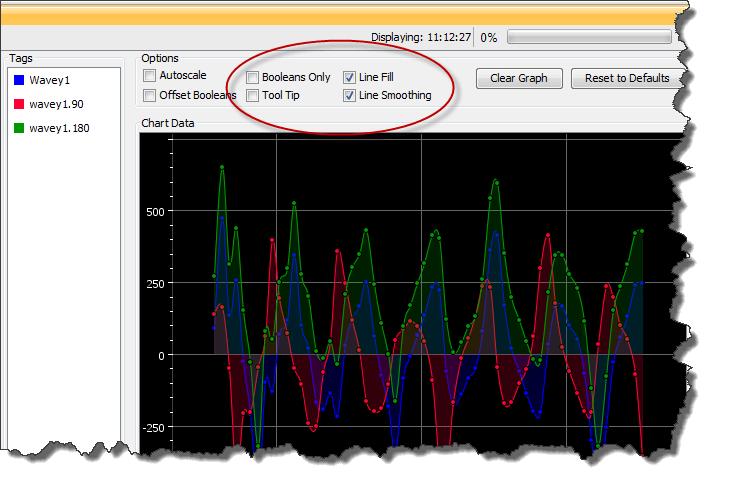

Data View graphing updated to allow options for line fill, line smoothing, and new tool tip to show data from a specific data point.

Enhanced Tag Export:

Tag Export & Project Save creates two separate files "name_extended.csv" & "name_basic.csv":

- Extended: Includes all fields used to edit/modify tags in the TagDB.

- Basic: Minimal fields used to import tags into Cmore and KepOPC.

What was new in Productivity Suite V1.9

Apple iOS PACDATA app

•

Go To Functionality

•

MST bit Descriptions

•

Add/Remove rows

New Apple iOS PACDATA app:

The FREE PAC Data Remote Monitor App allows the user to connect to remote PAC systems from a Wi-Fi, or cellular network connections. The Remote user can monitor the local PAC system and user tags configured for remote access inside the tag database of the PAC.

Click here for more info and to download the app.

- Monitor designated discrete and integer values within the PAC.

- Access Event History, Alarms, & critical & non-critical error logs.

- Access PAC web server if it is configured & view Data Log files.

- Can help system integrators and OEMs support equipment at remote sites.

- Separate Security Logon requirement offers additional protection for your data.

The Productivity3000 CPU must have compatible network settings with the device running the PACData App, or the CPU must be accessible from the Internet. Tags must be selected in TagDB prior to project downloaded for tags to be available for monitoring.

Go To Functionality

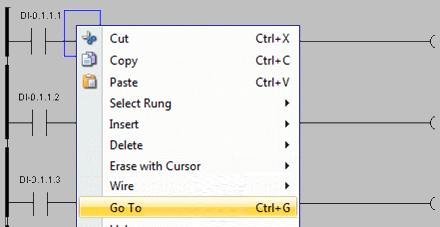

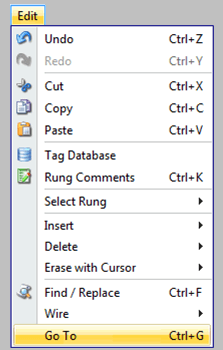

The Productivity Suite now supports a great new way to jump to a specific task (and rung or column) within your ladder code:

Right Click anywhere in your code, & select "Go To" from the drop menu...

...or Select "Go To" from the Edit Menu:

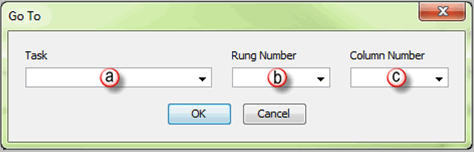

Either way - the Go To menu will appear:

- Select the task you wish to "Go To" (required)

- Select a Rung Number within that task (optional)

- Select a Column Number on that rung (optional)

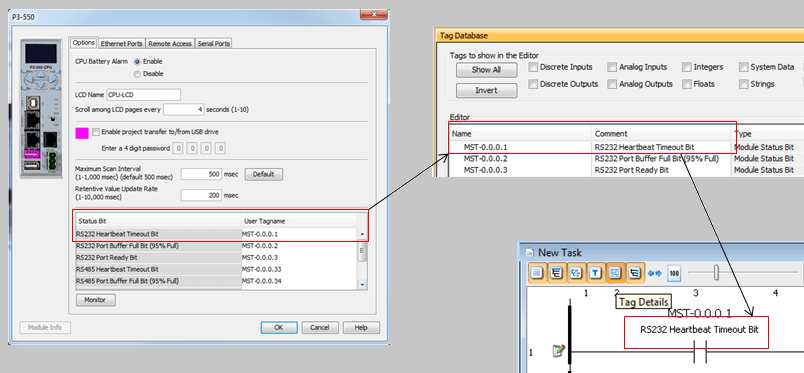

MST bit descriptions added as comments in the Tag Database

The descriptions for these bits were always shown on the hardware configuration screens, now you can access them via the tag database, and they will show up in your ladder code (if you choose to display tagname comments):

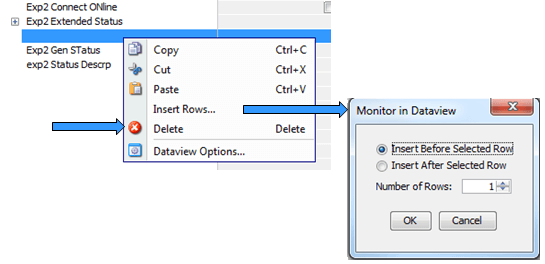

Add/Remove rows in Dataview

The software now allows insertion or deletion of a row(s) from a Dataview window

What was new in Productivity Suite V1.8

ViewMark Instruction

•

Improved Cross Reference

•

Value Cursor in Data View

•

Improved Hardware Configuration

•

Remote Access tab

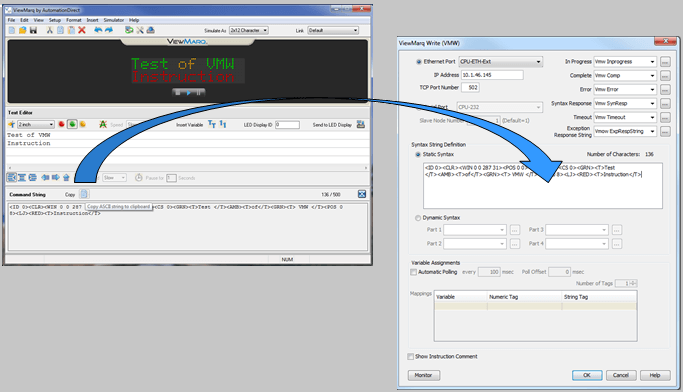

New ViewMark Write Instruction (VMW):

Configuring messages to send to a ViewMark message display is as easy as copying some text from the ViewMarq software into the new VMW instruction. The instruction can update Numerical and String Variables using Auto polling. The instruction allows the use of Static or Dynamic Syntax and can communicate via Ethernet, RS-232 & RS-485

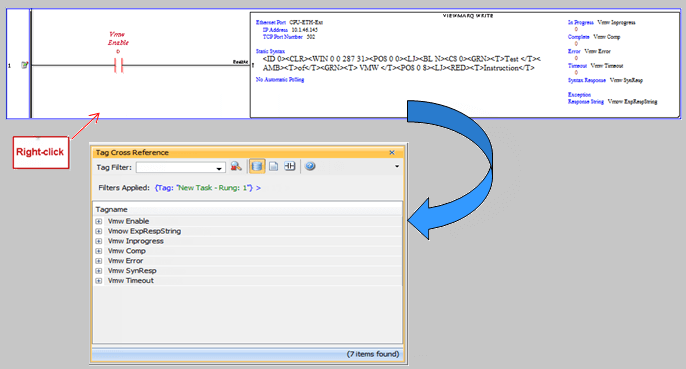

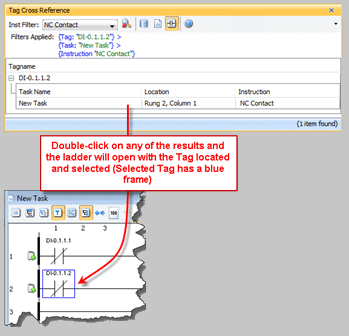

Improved Cross Reference:

Right click anywhere in your ladder to view the cross reference options. Filter on tags, tasks or instructions...

Expand any of the items in the list to view all instances of that element in your program. Then double-click to jump to that location in your code.

Value Cursor in Data View:

The new Value Cursor allows visual placement on a specific set of point(s). Hover the cursor to see the value of that point

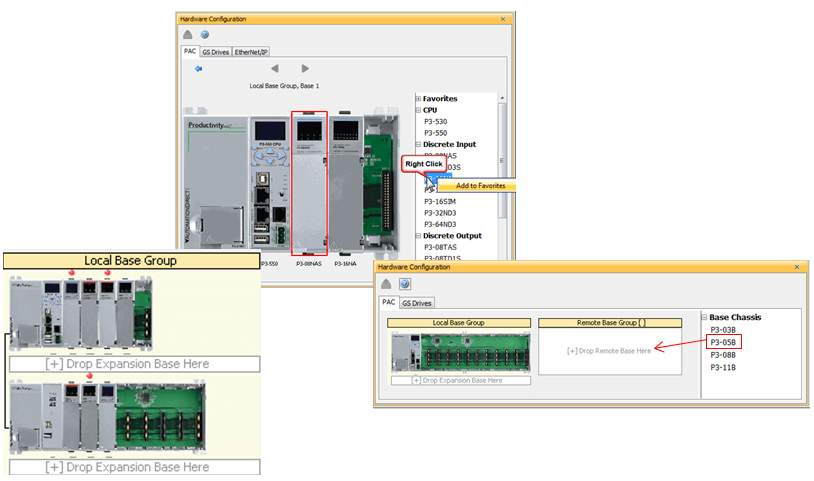

Improved Hardware Configuration Window:

The Hardware Configuration window has received a face-lift. Improved graphics, drag and drop capability for both modules and bases, as well as

clearly identifiable "hot swap" indicator for I/O modules that are hot swappable. And now you can right click system components in the menu

to create a personal list of favorites for those items that you use the most.

But don't forget about Auto Discovery, it is still the fastest way to configure

your Productivity3000 and any connected GS drives - just populate your rack and connect the drives, once you apply power and connect a programming

cable - just visit the Hardware Configuration dialog and click "Read Configuration". The Productivity Suite will read your entire setup

in a few seconds, and you'll be ready to start programming.

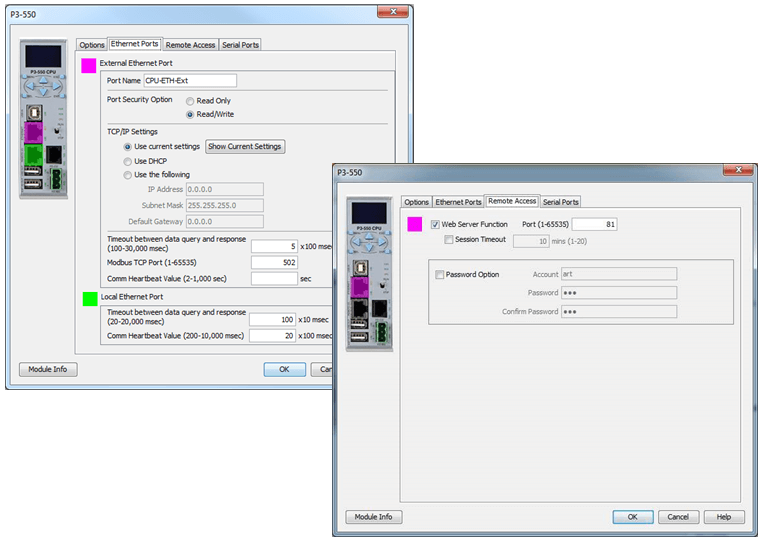

Remote Access Tab:

The web server setup configuration options have been moved to new Remote Access tab under the processor configuration dialog, in anticipation of an exciting new feature that will be added in the next release. Stay tuned for more details.

What (was) new in Productivity Suite V1.6

Web Server

•

High-Speed Instructions

•

High-Speed Module Testing

•

Bit of Word

•

PID Tuning Display

•

New Toolbars

•

Search & Replace Enhancements

•

Updated “Firmware update” Tool

•

Leading Zeros for PKS instruction

Web Server:

The P3-550 CPU now includes a web server. Click here for more info

High-Speed Instructions:

Several new instructions have been added to support the new High-Speed Input Module (P3-HSI) and the new High-Speed Output Module (P3-HSO).

- The Find Home (HOME) instruction allows the user to run a variety of homing routines. Homing is used to align the P3-HSO channel position a known real-world physical position

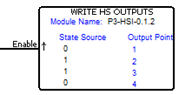

- The Write HS Outputs (WHSO) Instruction allows the user to set the state of outputs 3-6 on the P3-HSO module and outputs 1-4 on the P3-HSI module. The WHSO instruction allows these outputs to be controlled independently from the module's typical functions or for the purposes of bypassing the normal output operation

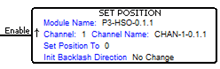

- The Set Position(SPOS) instruction will change the current position and/or backlash direction state for P3-HSO or P3-HSI channels

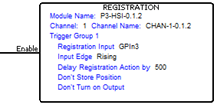

- The Registration (REG) instruction is an P3-HSI function and can be used to trigger several internal and external position based

events. Inputs can be used to trigger the capturing of positions, setting a tag, counting events and turning on, off or pulsing an output

- The related Registration Option is available in all high-speed move instructions (except Find Home). Using the P3-HSO's status inputs and status outputs, the Registration Option can trigger several internal and external position based events. Inputs can be used to trigger the capturing of a position, stopping a move and turning on, off or pulsing an output

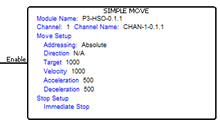

- The Simple Move (SMOV) instruction will create a motion profile based on a target position, target velocity, accel rate, decel rate, and optional Jerk value (for S-Curves)

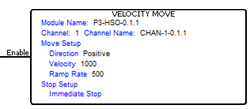

- The Velocity Move (VMOV) instruction will ramp to a target velocity at a user specified ramp rate. An optional Jerk value (for S-Curves) can be added to smooth the Acceleration or Deceleration. The target velocity and rate can be adjusted through tag values during the move, allowing users to create a continuously variable velocity profile under ladder control

Learn more about the new instructions in the help file (online here) or download the software (it's a free download).

High-Speed Module Testing

The High-Speed Module Tester is a software utility that allows a user to test the P3-HSO module's inputs and outputs. It is highly recommended to simulate your P3-HSO functions before attempting to control the module from your PAC program. This utility can be useful with debugging, confirming field wiring and verifying external device operation. The High-Speed Module Testing dialog box is accessed from the Application Tools window, a screen shot is shown below:

Bit of Word

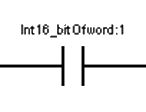

Programmers can now access an individual bit of any of the following 'word' data types:

- Integer 8 Unsigned

- Integer 16 Unsigned

- Integer 16

- Integer 16 BCD

- Integer 32

- Integer 32 BCD

To access a bit value, simply enter the tagname of the 'word tag' followed by ":" and the bit number (as shown at right).

Note: Since the token is a colon (:), any existing tagnames that contain this character must be changed in order to use this new feature. Once you enable the Bit of Word Tags option, the software will scan the project for existing tagnames that contain the Bit of Word Token (:) and assist you with a search and replace.

New Toolbars

The Ladder Editor, Data View, & Task Management toolbars have all been updated with new icons, and offer new features.

New Data View Features:

- Export 5 minutes of all Graphed Tags

- Ability to pause Graphing up to 10 minutes

- In addition, to play, skip fwd., & skip to current

New Task Management Feature:

- Synch Button: Selecting the Synch Button will synchronize the Task Management Panel to the Ladder Editor window. Once synchronized, if a task is selected in the Task Management Panel, that task will open for editing. If a task is selected in the Ladder Editor, it will be selected in the Task Management Panel.

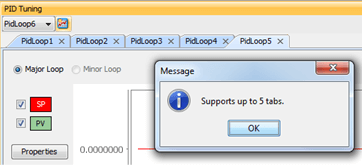

PID Tuning Updates

The PID Tuning dialog will now monitor (and allow you to tune) up to 5 separate PID loops without losing data as you move between the tabs. There are also two new ways to assign a PID loop to a tuning window, either 'right click' the PID instruction in your ladder task and select "PID Tuning", or choose the PID loop from the pull down menu in the upper left corner of the PID Tuning Dialog box.

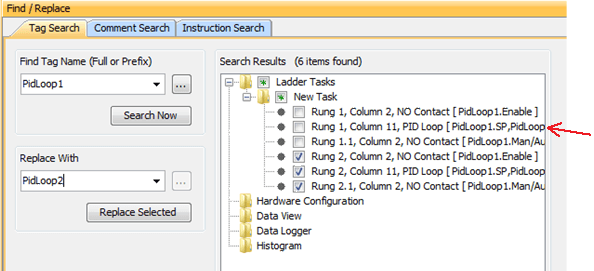

Search & Replace Enhancements

Partial Tagnames

The Find / Replace dialog now allows searches/replacement of partial tagnames. Great for cloning whole sections of code, just copy the rungs you wish to clone, and then search and replace on the beginning of the tagname strings, as shown in this example. The tagnames that are slated to be changed are shown on the very right of the list [in brackets]. Use the check boxes to make sure that tagnames are changed only on the desired rungs.

Tagnames listed to the right of the instruction are the tagnames that will be replaced if that line is 'checked'.

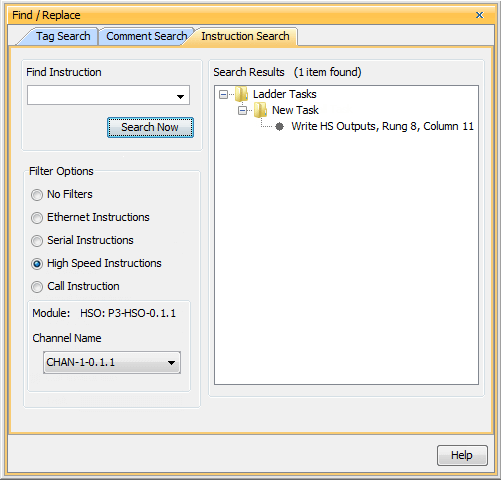

High-Speed Instruction/Module Filtering

You can also filter search results to only search the new High-Speed Instructions (HOME, REG, SMOV, SPOS, VMOV and WHSO). Results can be further refined by selecting a particular High-Speed module and/or channel.

Firmware Upgrade Tool

The Firmware Upgrade tool has been revamped with several new feature and enhancements:

- Ability to filter on the type of firmware file.

- Quickly compare the firmware version/type in the file to the version currently running in each module.

- Protection from loading incompatible firmware into a module.

- Select the new .adfw file format or read multiple firmware files in the .zip format.

- Ability to view firmware files off-line.

- Run/Stop switch (on P3-550 CPU)) must be in stop mode in order to perform upgrade.

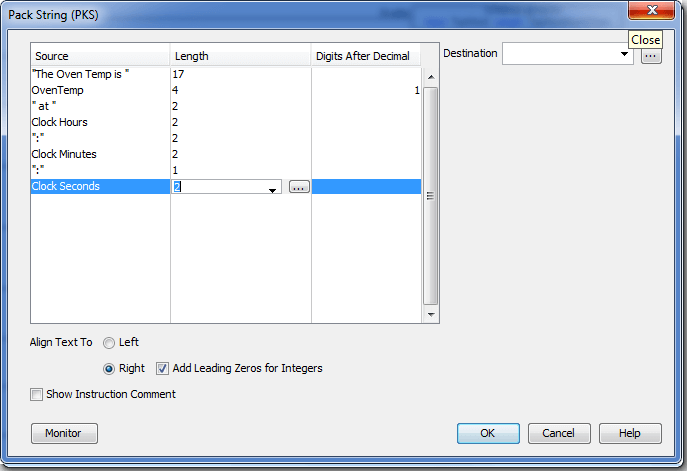

Leading Zeros for PKS Instruction

Allows selection of Left or Right justification. If Right align is selected, the Add Leading Zeros for Integers option can be selected.

Note: This is applied to all integer tags assigned to the instruction.

Check out our job openings

Free Online PLC Training

FREE Video Tutorials

FREE e-Newsletter

Automation Notebook

Product Literature

White Papers

News, Product and Training Bulletins

E-Books

Safe &

Secure

Safe &

Secure

We accept VISA, MasterCard, Discover, American Express, PayPal or company purchase orders.

Voted #1 mid-sized employer in Atlanta

Check out our

job openings