Cookies are not enabled on your browser.

Cookies are not enabled on your browser.Cookies are required for our site. Please enable cookies in your browser preferences to continue.

- Barcode / RFID / Vision

- Bulk Wire & Cable

- Cables (Terminated)

- Circuit Protection / Fuses / Disconnects

- Communications

- Drives & Soft Starters

- Enclosure Thermal Management & Lights

- Enclosures & Racks

- Field I/O

- HMI (Human Machine Interface)

- Hydraulic Components

- Motion Control

- Motor Controls

- Motors

- Pneumatic Components

- Power Products (Electrical)

- Power Transmission (Mechanical)

- Process Control & Measurement

- Programmable Controllers

- Pushbuttons / Switches / Indicators

- Relays / Timers

- Safety

- Sensors / Encoders

- Stacklights

- Structural Frames / Rails

- Tools & Test Equipment

- Valves

- Water (Potable) Components

- Wire & Cable Management

- Wire & Cable Termination

- Retired Products

Configuration Utilities

- PLC Family Selector

- P1000 PLC Systems

- P2000 PLC Systems

- P3000 PLC Systems

- ProductivityCODESYS

- CLICK PLC Systems

- Do-more® BRX PLC Systems

- LS-Electric® XGB PLC Systems

- Productivity®Open Systems

- Datalogic® Safety Light Curtains

- LS-Electric® Servo Systems

- Nitra® Pneumatic Grippers

- Object Detection (Sensors)

- PAL Controller Configurator

- Precision Gearbox Selector

- Protos X® Field I/O

- Pyrometers Selector

- Quadritalia® Modular Enclosures

- Stellar® Soft Starters

- Stepper System Selector

- SureFrame T-slot Extrusion

- SureMotion® XYZ Gantry

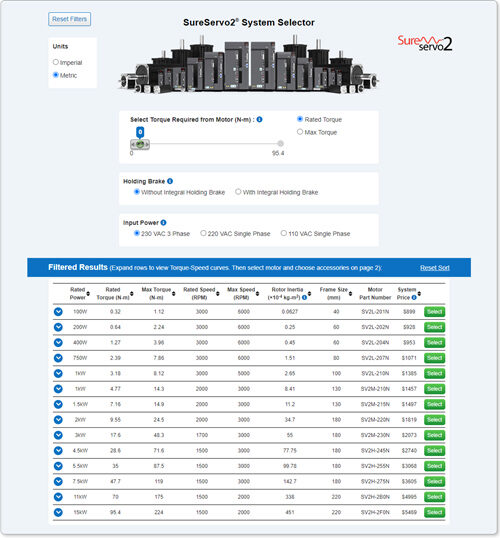

- SureServo2® System Selector

- SureStep® Linear Actuators

- Timing Belts & Pulleys

- Werma® Stacklights

- ZIPLinks

Use our selector tool to configure and order.

Replacement cooling fans are available for all SureServo2 servo drives that require fans.

This page will refresh momentarily.

Warning

Some of the selected facets have been selected by the {{ assistanceData.title }} Help.

Resetting/clearing ALL facets will end {{ assistanceData.title }} Help.

![Help icon]() Selection Assistance - {{ assistanceData.title }}

Selection Assistance - {{ assistanceData.title }}

Stride Interactive Product Tour Request

115/230V Servo Motors, Drives, Motor Cables

460V Servo Motors, Drives, Motor Cables

Servo CN1 I/O Components

Servo Accessories

Replacement Fans

Servo Connector Components

Replacement Fans

Choose components to create systems from 100W to 15kW

The AutomationDirect SureServo2 family of brushless servo systems is the newest edition of our flagship SureServo family. SureServo2 offers even more power and features (and at lower cost) than our previous offering (SureServo1). There are 26 standard permanent magnet servo motors that can be operated in combination with one of 16 standard servo drives:

System Features

- Precise control of position, velocity and torque at incredible prices!

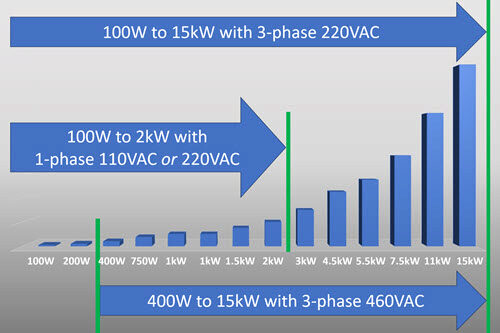

- Perfectly matched systems from 100W to 15kW:

- 120VAC single-phase input: 100W - 2kW

- 230VAC single-phase input: 100W - 2kW

- 230VAC three-phase input: 100W - 15kW

- 460VAC three-phase input: 400W - 15kW

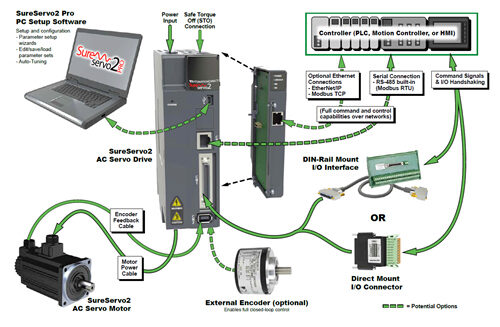

- Use with AutomationDirect CLICK, Do-more BRX, or Productivity series PLCs; LS-Electric XGB PLC; or any other host controller or HMI

- On-board motion controller with registration, electronic camming, and event-based logic control

- Option modules for EtherNet/IP and Modbus TCP provide factory networking capability

- Configuration software (FREE download, or order on USB device) allows for parameter upload/download, multiple auto-tuning modes, and includes a built-in oscilloscope for diagnostic and troubleshooting

- Field upgradeable firmware

- 30-day money-back guarantee

- Two-year warranty

Hardware Features:

- External encoder support provides full closed-loop control (i.e. to compensate for slippage between motor and load)

- 24-bit encoder has over 16 million PPR resolution (that's >46k pulses for ONE degree of motion). And the drive will scale to any input pulse resolution, while still maintaining this high degree of internal accuracy for all moves

- Absolute encoder (with battery backup) never loses position, even when drive power is disconnected

- Safe Torque Off (STO) for machine safety compliance without using bulky, expensive contactors

- Professionally manufactured cables for motor power, encoder feedback, and brake (optional), in standard or continuous flexing versions (3m, 5m, 10m, or 20m lengths)

SureServo2 Drives accept a wide range of command signals:

- Position commands:

- Pulse and direction

- "Count up / count down" format (CW/CCW)

- Built-in motion controller with up to 99 motion "segments"

- Select preset moves with switch inputs and/or the RS-485 Modbus serial interface

- Optional EtherNet/IP and ModbusTCP Ethernet modules allow full command and control options across your network

- Encoder follower

- Analog Velocity (+/-10V)

- Analog Torque (+/-10V)

- "On-the-Fly" control mode switching

- Registration

- Electronic camming

- Flying shear

- Logic/sequential control

Configuration, tuning and diagnostics:

- Integrated keypad/display for access to ALL drive parameters

- Take advantage of the FREE SureServo2® Pro PC-based configuration software

- Parameter upload/download/archive

- Parameter wizards for fast system commissioning

- Built-in oscilloscope lets you see exactly what is happening

- Allows firmware downloads to keep your drives up-to-date

- Multiple tuning modes:

- One Touch Auto Tuning - the drive tunes the motor without any motion (static motor/system analysis)

- Normal Auto Tuning - the drive tunes the load while an external controller or the drive's internal indexer provides point-to-point moves

- Assisted Tuning - three modes where the drive tunes the motor while moving. The user can adjust responsiveness while the drive is analyzing the system

- Manual Tuning - more than 20 parameters are available to give power users the ultimate flexibility to tune their systems

- Adapt to diverse applications with configurable I/O, including

- Ten (10) digital inputs

- Six (6) digital outputs

- Two (2) analog output signals

- One (1) secondary encoder input

- One (1) scalable encoder output

![]() SureServo2 AC Servo Systems Overview

SureServo2 AC Servo Systems Overview

![]() Download the FREE SV2-Pro Drive Configuration & Programming Software and Firmware

Download the FREE SV2-Pro Drive Configuration & Programming Software and Firmware

![]() SureServo2 Tutorial/Overview Videos

SureServo2 Tutorial/Overview Videos

Why Use a Servo?

The SureServo2 servo systems provide the highest possible level of performance for precise control of position, velocity, and torque. Compared to our previous SureServo1 family AND to other low-cost stepping systems, the SureServo2 products provide:

- More torque at higher speeds (up to 6,000 rpm)

- Broader range of power (up to 15kW)

- Higher response with closed-loop control (high hit rate without stalling or lost position)

For part listing and specifications, go to Shop Now

Check out our job openings

Free Online PLC Training

FREE Video Tutorials

FREE e-Newsletter

Automation Notebook

Product Literature

White Papers

News, Product and Training Bulletins

E-Books

Safe &

Secure

Safe &

Secure

We accept VISA, MasterCard, Discover, American Express, PayPal or company purchase orders.

Voted #1 mid-sized employer in Atlanta

Check out our

job openings

Loading...

Loading...