Cookies are not enabled on your browser.

Cookies are not enabled on your browser.Cookies are required for our site. Please enable cookies in your browser preferences to continue.

- Barcode / RFID / Vision

- Bulk Wire & Cable

- Cables (Terminated)

- Circuit Protection / Fuses / Disconnects

- Communications

- Drives & Soft Starters

- Enclosure Thermal Management & Lights

- Enclosures & Racks

- Field I/O

- HMI (Human Machine Interface)

- Hydraulic Components

- Motion Control

- Motor Controls

- Motors

- Pneumatic Components

- Power Products (Electrical)

- Power Transmission (Mechanical)

- Process Control & Measurement

- Programmable Controllers

- Pushbuttons / Switches / Indicators

- Relays / Timers

- Safety

- Sensors / Encoders

- Stacklights

- Structural Frames / Rails

- Tools & Test Equipment

- Valves

- Water (Potable) Components

- Wire & Cable Management

- Wire & Cable Termination

- Retired Products

Configuration Utilities

- PLC Family Selector

- P1000 PLC Systems

- P2000 PLC Systems

- P3000 PLC Systems

- ProductivityCODESYS

- CLICK PLC Systems

- Do-more® BRX PLC Systems

- LS-Electric® XGB PLC Systems

- Productivity®Open Systems

- Datalogic® Safety Light Curtains

- LS-Electric® Servo Systems

- Nitra® Pneumatic Grippers

- Object Detection (Sensors)

- PAL Controller Configurator

- Precision Gearbox Selector

- Protos X® Field I/O

- Pyrometers Selector

- Quadritalia® Modular Enclosures

- Stellar® Soft Starters

- Stepper System Selector

- SureFrame T-slot Extrusion

- SureMotion® XYZ Gantry

- SureServo2® System Selector

- SureStep® Linear Actuators

- Timing Belts & Pulleys

- Werma® Stacklights

- ZIPLinks

Use our selection assistance tool to narrow your search.

Photoelectric sensors detect presence, distance, or color using light via through-beam, retroreflective, or diffuse sensing modes. Specialized types, such as fiber optic and fork sensors, are also available; certain models offer IO-Link and smart functionality for advanced data and configuration.

This page will refresh momentarily.

Warning

Some of the selected facets have been selected by the {{ assistanceData.title }} Help.

Resetting/clearing ALL facets will end {{ assistanceData.title }} Help.

![Help icon]() Selection Assistance - {{ assistanceData.title }}

Selection Assistance - {{ assistanceData.title }}

Stride Interactive Product Tour Request

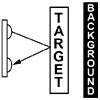

Background Suppression

Diffuse

Retroreflective

Through-Beam

Fiber Optic Sensors

Fork Sensors

Reflectors, Lens Adapters and Splitters

Mounting Brackets and Rods

Sensor Tester and Spare Parts

Photoelectric Sensors

Photoelectric sensors use light and optics to detect object presence, color, or distance. Standard models provide discrete or analog outputs; smart sensors offer advanced functionality; and models with IO-Link capability supply measurement, diagnostic, performance, and configuration data. Photoelectric sensors from brands such as Autonics, Contrinex, Datalogic, di-soric, Eaton, Leuze, Micro Detectors, and Wenglor, as well as our own AchieVe, AutomationDirect, and ProSense brands, can detect a wide variety of materials and measure distances from a few millimeters up to hundreds of meters.

For part listing and specifications, go to Shop Now

Background Suppression

Newest Additions!

- AchieVe FBM series rectangular photoelectric sensors

- Contrinex IO-Link smart photoelectric sensors

Diffuse photoelectric sensors with background suppression detect objects by sensing reflected light. They offer reliable detection by ignoring surrounding objects and provide a stable sensing distance regardless of target color. Some models use blue light to accurately sense dark or shiny targets.

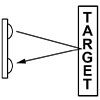

Diffuse

Newest Additions!

- Contrinex IO-Link smart photoelectric sensors

Diffuse photoelectric sensors combine an emitter and receiver into a single compact housing. They sense presence, color, or contrast by emitting a light beam and sensing the light reflected directly from the target. They are easy to install and adjust, but typically have shorter sensing distances.

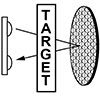

Retroreflective

Newest Additions!

- AchieVe FBM series rectangular photoelectric sensors

- Contrinex IO-Link smart photoelectric sensors

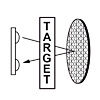

Retroreflective sensors bounce light off a fixed reflector; a target is detected when it breaks the beam. They offer longer sensing distances than a diffuse style but require alignment of the sensor and reflector. Polarized models improve detection accuracy by filtering out ambient light sources.

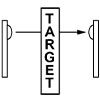

Through-Beam

Newest Additions!

- AchieVe FBM series rectangular photoelectric sensors

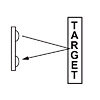

Through-beam photoelectric sensors consist of an emitter and a receiver in separate housings. The emitter sends a beam of light to the receiver, which determines a target is present when the beam is interrupted. These sensors offer the longest sensing distances but require precise alignment.

Fiber Optic Sensors

Fiber optic sensors provide a remotely mounted electronics and optics package with fiber optic extensions to the sensing area. They offer supreme noise protection, and their small size is perfect for extremely tight locations or where even low-power electronics are not allowed.

Fork Sensors

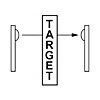

Fork sensors (also called slot or "U" sensors) offer advantages over standard through-beam sensors, including identical mechanical / optical axis, operational reliability and repeatability with transmitter and receiver built into the same housing.

Reflectors, Lens Adapters and Splitters

Reflectors, lens adapters, shutters, and splitters are available for proper operation and detection or to alter the size and/or path of the emitted light for specialized installations.

Mounting Brackets and Rods

Brackets and adapters are available in various materials for mounting tubular and rectangular photoelectric sensors.

Sensor Tester and Spare Parts

Replacement hex nuts and a sensor tester are available to securely install and validate the operation of photoelectric sensors.

Check out our job openings

Free Online PLC Training

FREE Video Tutorials

FREE e-Newsletter

Automation Notebook

Product Literature

White Papers

News, Product and Training Bulletins

E-Books

Safe &

Secure

Safe &

Secure

We accept VISA, MasterCard, Discover, American Express, PayPal or company purchase orders.

Voted #1 mid-sized employer in Atlanta

Check out our

job openings

Loading...

Loading...