Cookies are not enabled on your browser.

Cookies are not enabled on your browser.Cookies are required for our site. Please enable cookies in your browser preferences to continue.

- Barcode / RFID / Vision

- Bulk Wire & Cable

- Cables (Terminated)

- Circuit Protection / Fuses / Disconnects

- Communications

- Drives & Soft Starters

- Enclosure Thermal Management & Lights

- Enclosures & Racks

- Field I/O

- HMI (Human Machine Interface)

- Hydraulic Components

- Motion Control

- Motor Controls

- Motors

- Pneumatic Components

- Power Products (Electrical)

- Power Transmission (Mechanical)

- Process Control & Measurement

- Programmable Controllers

- Pushbuttons / Switches / Indicators

- Relays / Timers

- Safety

- Sensors / Encoders

- Stacklights

- Structural Frames / Rails

- Tools & Test Equipment

- Valves

- Water (Potable) Components

- Wiring Solutions

- Retired Products

- Programmable Logic Controllers

- Productivity1000 PLCs

- Productivity2000 PLCs

- Productivity3000 PLCs

- ProductivityCODESYS

- LS Electric XGB Series PLCs

- ProductivityOpen

- CLICK PLCs

-

Do-more H2 PLCs or

Do-more T1H Series - Do-more BRX PLCs

- C-more Touch Panels

- AC & DC Drives

- Motion Control Components

- Servos

- StrideLinx

- Pneumatics

Configuration Utilities

- PLC Family Selector

- P1000 PLC Systems

- P2000 PLC Systems

- P3000 PLC Systems

- ProductivityCODESYS

- CLICK PLC Systems

- Do-more® BRX PLC Systems

- LS-Electric® XGB PLC Systems

- Productivity®Open Systems

- AC Motors

- Datalogic® Safety Light Curtains

- LS-Electric® Servo Systems

- Nitra® Pneumatic Grippers

- Object Detection (Sensors)

- PAL Controller Configurator

- Precision Gearbox Selector

- Protos X® Field I/O

- Quadritalia® Modular Enclosures

- Stellar® Soft Starters

- Stepper System Selector

- SureFrame T-slot Extrusion

- SureMotion® XYZ Gantry

- SureServo2® System Selector

- SureStep® Linear Actuators

- Timing Belts & Pulleys

- Werma® Stacklights

- ZIPLinks

![]()

For the best experience with this configuration tool,

please view with a desktop browser.

Controller Selector

Controller Type

Info

- Traditional PLCs are primarily focused on logic operations, and use traditional PLC programming languages (your preferred/required programming languages can be specified below). Most traditional PLCs also support motion control operations with pulse train output (PTO).

- Open Source Controllers can control logic operations and more - often via the use of third party libraries. Programming languages include the IEC 61131 languages (CODESYS), CircuitPython & C++ (ProductivityOpen), and Node-RED & JavaScript (CLICK PLUS w/Node_RED). Open source controllers from AutomationDirect do not support motion control at this time.

- EtherCAT Motion Controllers excel at motion control operations, but they include all the logic capabilities of a traditional PLC also. Motion control is accomplished over the high speed, deterministic EtherCAT protocol. Programming languages include relay ladder and other IEC 61131 languages (your preferred/required programming languages can be specified below).

I/O

Info

PLCs use discrete inputs and outputs to monitor and control binary devices. For example, if a limit switch detects the presence of an object, it provides an "ON" input signal to the PLC; if no object is detected, it provides an "OFF" signal (or the lack of any signal). An example of a discrete output is a light, the PLC outputs an "ON" signal to turn on the light, and outputs an "OFF" signal (more accurately, the lack of a signal) to turn off the light.

NOTE: The values used by this selector are for natively addressable I/O. Thousands more I/O points can often be accessed by various networking operations (MODBUS 'reads' and 'writes' for example).

Why this is important: The number and type of devices your system will include is directly linked to the amount of I/O that will be necessary for your system. You will need to choose a controller that supports your I/O count requirements and has modules that support your signal types.

Info

PLCs use analog inputs and outputs to monitor and control continuous signals which vary over time. An example of an analog input is a thermocouple (an industrial thermometer); which sends a continuously varying temperature signal in to the PLC. An example of an analog output might be a motor speed command, where a 0 volt signal commands a zero speed (stopped), ranging up to a 10 volt signal which indicates that the motor should spin at full speed.

NOTE: The values used by this selector are for natively addressable I/O. Thousands more I/O channels can often be accessed by various networking operations (Modbus 'reads' and 'writes' for example).

Why this is important: The number and type of devices your system will include is directly linked to the amount of I/O that will be necessary for your system. You will need to choose a controller that supports your I/O count requirements and has modules that support your signal types.

Info

High speed inputs are needed when input signals may fluctuate faster (or nearly so) than the scan time of the PLC. The signals can't be processed via the "normal scan" of the PLC, therefore special input hardware is needed to capture the frequency of the signals. Most PLCs provide a method for handling such signals, and the programmer can access info about the frequency in the ladder logic, without having to process each and every transition itself.

Info

High speed outputs are similarly to the high speed inputs, and for the same reason: it is not practical to program the high-speed switching in the ladder code. The programmer can stipulate a frequency, and the PLC hardware handles the actual switching, independent of the ladder logic scan. High speed outputs are often used for motion control (positioning) applications, where the frequency of the PLC output is used by a servo or stepper system to determine a desired motor shaft position, or the length of a particular "move". These signals are often referred to as "step and direction signals. Take a look at our SureStep™ stepper systems and our SureServo™ servo systems. And search on the phrase "step and direction" for more info about using PLCs as motion controllers.

AutomationDirect now offers motion controllers (PLCs) that use the EtherCAT protocol to send highly-precise motion commands over an Ethernet network (see below for additional motion control related selection criteria). With network control, the wiring complexity is greatly reduced and you may not need any high-speed outputs for motion control applications.

Info

Serial and Ethernet-based Expansion I/O hardware are two popular options. This I/O may also be referred to as distributed I/O, and may require a particular protocol, such as Modbus.

Local Expansion I/O refers to an additional rack of I/O modules located near the main rack. Local I/O is typically required when the necessary I/O modules simply will not fit in the main rack. Response times are excellent, as Local I/O is typically updated "every scan" along with the I/O in the main rack.

Remote I/O refers to I/O modules that are housed in a separate rack, typically in a remote location (although sometimes remote I/O is installed near the main PLC rack). Remote I/O can be very advantageous, especially with large, far flung machinery, and can reduce wiring costs significantly. Response times are good, but the communications distance typically means that I/O will be updated asynchronously from the scan.

Info

PWM is a method of dynamically reducing the effective power delivered by an electrical signal by dividing it into discrete pulses, which vary in width and frequency. Often used for controlling DC motors, PWM is also used to control valves, pumps, hydraulics, and other mechanical parts.

Communication

Info

Ethernet is used by PLCs for communications to various types of devices; from other controllers, AC motors and drives to sophisticated sensors. All AutomationDirect PLCs that have an Ethernet port will also allow programming across the Ethernet link.

Info

Serial ports are used for a wide range of communication functions. From a hardware standpoint there are two popular types — RS-232, used for point-to-point serial connections; and RS-485, used for multi-drop connections to multiple devices. Serial devices may also require a particular software protocol. Common serial protocols include Modbus RTU and ASCII (both are supported by ALL AutomationDirect PLCs).

Info

Paraphrased from Wikipedia, the free encyclopedia: http://en.wikipedia.org/wiki/EtherNet/IP

EtherNet/IP is an industrial Ethernet network that combines standard Ethernet technologies with the media-independent Common Industrial Protocol or "CIP." EtherNet/IP is one of the leading industrial Ethernet networks in the world and is widely used in a range of industries including discrete manufacturing and process controls. The EtherNet/IP and CIP technologies are managed by ODVA, Inc., a trade and standards development organization.

The EtherNet/IP standard defines the features and functions for its transport, network, data link and physical layers. CIP uses its object-oriented design to provide EtherNet/IP with the services and device profiles needed for real-time control applications and to promote consistent implementation of automation functions across a wide variety of products.

Info

Modbus TCP communication refers to a method of data exchange between industrial devices using the Modbus protocol, which is transported over a TCP/IP network, essentially allowing devices to communicate over Ethernet using a standardized format for data exchange, making it ideal for industrial automation systems where multiple devices need to share information across a network; the "TCP" part indicates that the communication relies on the Transmission Control Protocol for reliable data delivery.

The Modbus message structure remains the same as in other/older Modbus protocols, including a function code to specify the desired operation (read, write, etc.) and data registers to store the values.

Info

Ethernet for Control Automation Technology (EtherCAT) was originally developed by Beckhoff Automation in the early 2000's (they then donated the rights so that the protocol could be standardized under IEC 61158). EtherCAT works on standard Ethernet architectures, using a single master device to initiate a datagram frame which is sequentially passed through associated network nodes. This messaging structure eliminates data "collisions", enabling short and deterministic cycle times, so that accurate synchronization can be maintained among all communicating devices.

EtherCAT enables a wide range of motion applications and the network wiring is simple and fast. The EtherCAT controller has access to the position, velocity, and torque of all axes of motion - so there are very few application limitations.

Select "EtherCat Motion Controllers" (or "Show All") under Controller Type above to see all available EtherCAT controllers.

Info

Modbus RTU is a serial communication protocol used in industrial automation, allowing devices like sensors, actuators, and PLCs to exchange data over a serial line (typically using RS-485) with a master-slave architecture, where a single master device initiates requests to read or write data from multiple slave devices, each identified by a unique address; communication occurs in a half-duplex mode, meaning only one device can transmit data at a time, and data is transmitted in a structured format with error checking using a Cyclic Redundancy Check (CRC) to ensure data integrity.

All Automation Direct controllers with serial ports support Modbus RTU communications.

Info

ASCII serial communication refers to a method of transmitting data over a serial connection where each character is represented using the ASCII encoding standard, meaning each letter, number, and symbol is converted into a unique binary code that can be sent one bit at a time.

All Automation Direct controllers with serial ports support ASCII communications.

Info

MQTT stands for MQ Telemetry Transport. It is a publish/subscribe, extremely simple and lightweight messaging protocol, designed for constrained devices and low-bandwidth, high-latency or unreliable networks. The design principles are to minimize network bandwidth and device resource requirements while attempting to ensure reliability and some degree of delivery assurance. These principles also turn out to make the protocol ideal of the emerging "machine-to-machine" (M2M) or "Internet of Things" world of connected devices, and for mobile applications where bandwidth and battery power are at a premium - from http://mqtt.org/

Info

In network communication, UDP (User Datagram Protocol) and TCP (Transmission Control Protocol) are two different protocols used to transfer data between devices, with the key difference being that UDP is "connectionless" and prioritizes speed, while TCP is "connection-oriented" and prioritizes reliable data delivery, meaning it ensures all data packets arrive in order and without errors, even if it takes longer to transmit; making UDP ideal for applications like live streaming or gaming where fast response is crucial, while TCP is better suited for email or file transfers where data integrity is paramount.

UDP features:

- Connectionless: No need to establish a connection before sending data, which allows for faster transmission.

- Less reliable: Packets may be lost or arrive out of order as there is no error checking or retransmission mechanism.

- Low overhead: Minimal processing required to send data, leading to faster speeds.

- Connection-oriented: Requires a handshake process to establish a connection before data transfer can begin.

- Reliable: Uses error detection and retransmission mechanisms to ensure all data is delivered correctly.

- Higher overhead: More processing is needed to manage connections and error checking, potentially slowing down transmission.

Info

The WebSocket protocol enables full-duplex interaction between a web browser (or other client application) and a web server with lower overhead than half-duplex alternatives such as HTTP polling, facilitating real-time data transfer from and to the server. This is made possible by providing a standardized way for the server to send content to the client without being first requested by the client, and allowing messages to be passed back and forth while keeping the connection open. In this way, a two-way ongoing conversation can take place between the client and the server. The communications are usually done over TCP port number 443 (or 80 in the case of unsecured connections), which is beneficial for environments that block non-web Internet connections using a firewall. Additionally, WebSocket enables streams of messages on top of TCP. TCP alone deals with streams of bytes with no inherent concept of a message.

Info

The Hypertext Transfer Protocol (HTTP) works as a request-response protocol between a network client and server. A client submits a request to the server; then the server returns a response to the client. The response contains both status information about the request itself, and the requested content if applicable. The PLC client communicates with the HTTP server using the following 5 commands: GET which is used to request data from a specified resource. HEAD which is almost identical to GET, but without returning data in the Response Body, POST and PUT which are used to send data to a server to create or update a resource, and DELETE which removes the specified resource.

Info

From Wikipedia, the free encyclopedia: http://en.wikipedia.org/wiki/DMX512

DMX512 (Digital Multiplex) is a standard for digital communication networks that are commonly used to control stage lighting and effects. It was originally intended as a standardized method for controlling light dimmers, which, prior to DMX512, had employed various incompatible proprietary protocols. It soon became the primary method for linking controllers (such as a lighting console) to dimmers and special effects devices such as fog machines and intelligent lights. DMX has also expanded to uses in non-theatrical interior and architectural lighting, at scales ranging from strings of Christmas lights to electronic billboards. DMX can now be used to control almost anything, reflecting its popularity in theaters and venues.

DMX512 is unidirectional and employs EIA-485 differential signaling at its physical layer, in conjunction with a variable-size, packet-based communication protocol.

Info

The File Transfer Protocol (FTP) is a standard network protocol used for the transfer of computer files between a client and server on a computer network. FTP is built on a client-server model architecture using separate control and data connections between the client and the server.

Info

The Simple Mail Transfer Protocol (SMTP) is an internet standard communication protocol for electronic mail transmission. Mail servers and other message transfer agents use SMTP to send and receive mail messages.

Info

The Short Messaging Service (SMS) protocol is commonly known as text messaging. The SMS protocol allows sending text messages of up to 160 characters to cell phones.

Info

The OPC UA Server protocol is a standardized communication standard: "OPC Unified Architecture", used in industrial automation to enable secure and platform-independent data exchange between different devices, systems, and software applications from various vendors, essentially acting as a central hub for accessing and managing industrial data across a network by providing a client-server architecture where a server exposes data to requesting clients; it is considered a successor to the older OPC Classic protocol and is designed to be highly extensible and secure with features like encryption and authentication.

Programming & Hardware

Info

Serial ports are used for a wide range of communication functions. From a hardware standpoint there are two popular types — RS-232, used for point-to-point serial connections; and RS-485, used for multi-drop connections to multiple devices. Serial devices may also require a particular software protocol. Common serial protocols include Modbus RTU and ASCII (both are supported by ALL AutomationDirect PLCs with serial ports).

Info

AutomationDirect offers a choice of PLC form factors:

-

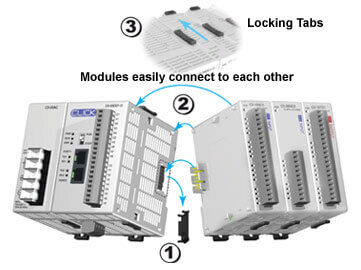

Stackable Brick: Our CLICK and BRX PLCs can function as standalone controllers with a handful of inputs and outputs

built-in to the CPU — or you can add up to eight modules, "stacked" to the right of the CPU. The P1000 is also

a stackable design - but the CPU has no built-in I/O. Stackable PLCs take up only as much space as is needed for the

amount of I/O required.

-

Rack-based: P2000 and P3000 Productivity Series PLCs require a rack (sometime called a base), and these racks are available

in various lengths depending on how many modules may be required for a particular application.

Info

Fixed type refers to the classic PLC memory naming convention, with abbreviations such as "I" for integer, or "S" for String, followed by a number to differentiate the various bits and words. Examples such as I34, or S105, may seem familiar to many PLC programmers.

Tagnames are a more recent method for naming the memory locations, whereby the programmer is allowed to define logical names to the variables 'at will' — even prior to determining what type of memory location is required. There are a few rules governing the selection of names, and there are many conventions that can make life much easier for the programmer. The software does automatic housekeeping of all memory locations. There is no concern about physical addressing and memory conflicts.

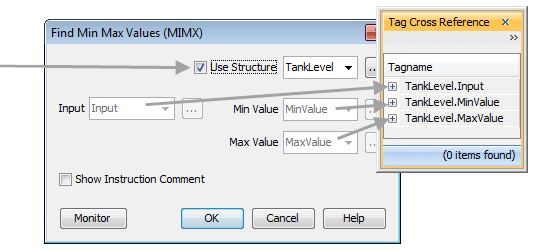

Tagnames also lend well to the use of structure data types. Structures (and their associated tagnames) are defined based on function rather than data type.

Structure data types:

Structure data types are specific sets of tags combined together for convenience. Using Structures in instructions can speed up program development because multiple tags are created and assigned automatically. In the Productivity Suite, for example, you simply check the "Use Structure" box and enter the name for your structure. The Productivity Suite software does the rest, creating all the tags required for that instruction.

Info

Paraphrased from Wikipedia, the free encyclopedia: http://en.wikipedia.org/wiki/PID_controller

Proportional-integral-derivative control (PID control) is a control loop feedback technique widely used in industrial control systems. A PID loop calculates an error value as the difference between a measured process variable and a desired setpoint. The controller attempts to minimize the error by adjusting the process through use of a manipulated variable.

Info

USB is a fast and easy way ("Plug and Play") to connect to a PLC and program, troubleshoot, and/or monitor your PLC application.

Info

Wi-Fi enables a wireless Ethernet connection for installation, programming and communications to factory devices.

Info

While data logging is a reasonably simple feature to add to most control systems, the Do-more BRX, Productivity1000, Productivity2000 and Productivity3000 PLCs offer built-in data logging. With the Productivity1000 and 2000, a microSD card can be inserted into the front of the CPU module to store data. With the Productivity3000, a USB memory stick can be plugged into the CPU for similar functionality. For BRX, 1MB of internal RAM is available to use as data storage along with data logging to an external microSD card.

With these PLCs, the data can be retrieved by physically accessing the flash memory device, or the files can be accessed by enabling the optional built-in webserver or by sending the log files via e-mail (if e-mail is enabled for the PLC) on a periodic or on-demand basis.

Info

Info

Dashboard tools make it fast and easy to create web pages which display data from your controller:

WebVisu is an open source product for CODESYS controllers that allows users to operate and monitor machines, plants, and installations using an internet browser. It can also be used to create visualizations and operator interfaces, display control and production data, and optimize information display on different web-based end devices. WebVisu can be used for remote access, remote monitoring, and service and diagnostics of an application over the internet.

Node-RED Dashboard is a module for Node_RED controllers that provides a set of nodes to quickly create a live data dashboard. It provides nodes to quickly create a user interface with buttons, sliders, charts, gauges, etc. After installing, the dashboard nodes will show up in the palette and nodes from the dashboard section provide widgets that show up in your application user interface (UI).

Info

Programming Languages

Info

Ladder logic is a programming language for PLCs that represents the program with a graphical diagram based on the circuit diagrams of relay hardware. The name is based on the similarity of the programs written in this language to a physical ladder, with two vertical rails and a series of horizontal rungs between them. Ladder logic is a recognized programming language within the IEC 61131-3 standard. All of the IEC 61131 languages share Common Elements. The variables and function call are defined by the common elements so different languages can be used in the same program (assuming the PLC supports the additional languages).

Info

Structured text is used for PLC programming and is a recognized programming language within the IEC 61131-3 standard. Structured Text is a stripped-down version of the C (or C++) computer programming language, and the syntax is very similar. If you are familiar with any of the C languages, then Structured Text will feel very comfortable. All of the IEC 61131 languages share Common Elements. The variables and function call are defined by the common elements so different languages can be used in the same program.

Info

Sequential function chart (SFC) is a visual programming language used for PLCs. It is one of the languages defined by the IEC 61131-3 standard. SFC is a parallel programming language where multiple control flows (or Program Organization Units) can be active at once. All of the IEC 61131 languages share Common Elements. The variables and function call are defined by the common elements so different languages can be used in the same program.

Info

The function block diagram (FBD) is a graphical language for programming language for PLCs that describes the function between input variables and output variables. A function is described with a set of elementary blocks. Input and output variables are connected to blocks by connection lines. All of the IEC 61131 languages share Common Elements. The variables and function call are defined by the common elements so different languages can be used in the same program.

Function Block programming is (currently) specific to the ProductivityCODESYS controller

Info

Instruction list (IL) is one of the languages supported by the initial versions of IEC 61131-3 standard, and subsequently deprecated in the third edition.

It is used for programming PLCs. It is a low level language which resembles assembly. All of the IEC 61131 languages share Common Elements. The variables and function call are defined by the common elements so different languages can be used in the same program.

Instruction List programming is (currently) specific to the two LS controllers

Info

CircuitPython is an open-source derivative of the MicroPython programming language targeted toward students and beginners. It is a software implementation of the Python 3 programming language, written in C, and designed to be easy to read, write and maintain. It supports modules and packages to facilitate code reuse, and it has a built-in interpreter so compiling isn't needed.

CircuitPython programming is (currently) specific to the ProductivityOpen controller

Info

C++ is a general-purpose, object-oriented language, emphasizing data fields with unique attributes (objects), instead of functions or logic. It is well suited to both embedded systems (programs that run on limited computing resources) and real-time processing and control systems.

C++ programming is (currently) specific to the ProductivityOpen controller

Info

Node-RED is a programming tool for wiring together hardware devices, APIs and online services in interesting ways. It provides a browser-based editor that makes it easy to wire together flows using the wide range of nodes in the palette that can be deployed to its runtime in a single-click.

The light-weight runtime is built on Node.js, taking full advantage of its event-driven, non-blocking model. This makes it ideal to run at the edge of the network on low-cost hardware. With over 225,000 modules in Node's package repository, it is easy to extend the range of palette nodes to add new capabilities.

The flows created in Node-RED are stored using JSON which can be easily imported and exported for sharing with others.

Node-RED programming is (currently) specific to the CLICKPLUS with Node-RED controller

Info

JavaScript is a versatile, dynamically typed programming language used to add dynamic interactions to web pages, applications, servers, and even games. It supports both client-side and server-side development, and integrating seamlessly with HTML, CSS, and standard libraries.

JavaScript programming is (currently) specific to the CLICK-Plus with Node-RED controller

Motion Control

Info

Typical axes of motion might be servo or stepper systems. These types of systems are capable of precise position, velocity, and sometimes torque control. These axes may include encoder or other feedback devices to ensure that the motor shaft reaches and maintains the commanded position (or velocity), even when dynamic forces affect the load.

The number of axes that can be controlled varies by controller family, and additional hardware is sometimes required:

- CLICK PLUS PLC - up to three axes of PTO control is available when a DC slot module is present in the first CPU expansion slot. No further motion expansion is possible.

- Do-more BRX PLC - DC powered CPUs provide up to 3 axes of PTO control natively, and each additional BX-HSIOx I/O module adds additional axes (HSIO1 adds 1 axis, HSIO2 adds 2, HSIO4 adds 4). A max of 27 axes can be controlled, in coordinated groups of 7 axes each. Virtual axes are supported.

- Productivity1000 PLC - add one PS-AMCx controller to control up to 4 axes of motion with PTO.

- Productivity2000/3000 PLCs - add up to 4 PS-AMCx controllers to control up to 16 axes of PTO motion (in four coordinated groups of 4). Px-HSO modules can also be added to the local PLC rack to add 2 axes each of PTO control.

- LS Electric XGB PLC - most CPUs support PTO control of either 2-axes or 6-axes. All systems can be expanded with XBF-PNxxB EtherCAT modules for up to 16 axes of EtherCAT motion. Up to 16 virtual axes are also supported.

- LS Electric XMC Motion Controller - CPUs support either 8 or 16 axes of EtherCAT motion natively. Up to 18 virtual axes are also supported.

Info

The most common version is pulse and direction where one output from the controller pulses rapidly to command small increments of motion, while a second output dictates the direction of travel. Clock-wise/counter clock-wise pulses are a second option - with one output commanding motion increments in one direction, and vice versa.

PTO is a well established method of control, but it does have limitations. The wiring can get complex, especially as the axes count increases. While most servo (and some stepper) systems close the loop internally (on a per axis basis), there is no provision for loop closure with the controller, so full closed loop applications may require additional hardware and wiring.

Info

Ethernet for Control Automation Technology (EtherCAT) was originally developed by Beckhoff Automation in the early 2000's (they then donated the rights so that the protocol could be standardized under IEC 61158). EtherCAT works on standard Ethernet architectures, using a single master device to initiate a datagram frame which is sequentially passed through associated network nodes. This messaging structure eliminates data "collisions", enabling short and deterministic cycle times, so that accurate synchronization can be maintained among all communicating devices.

EtherCAT enables a wide range of motion applications and the network wiring is simple and fast. The EtherCAT controller has access to the position, velocity, and torque of all axes of motion - so there are very few application limitations.

Info

While this works for many simple applications, there are limitations. There is no synchronization between axes, so no coordinated motion. And only certain servo and stepper systems are available with the appropriate networking hardware.

Often the application functionality is dependent on the drive hardware:

- Registration is possible over EtherNet/IP or ModbusTCP networks with LS PHOX and iX7 drives, because these drives have Capture/Probe inputs; but the correction calculation must be performed in the controller (and there may not be a function block in the controller, so the calcs may have to be done with standard ladder functions) and response times will be subject to the scan time of the controller.

- SureServo2 servo drives can handle some registration applications natively (completely in the drive hardware) - and report success over the EIP or ModTCP network.

- LS Electric DC PHOX systems and SureServo2 servo systems can accomplish Encoder Following (or Full-closed-loop-control) with the controller and drive connected via EtherNet/IP or ModbusTCP, but the external encoder is wired into the drive. So, this is more of a drive feature/function and it is limited to a single axis of "following", unless the encoder signal is cascaded (or daisy-chained) to other drives. (In contrast, an external encoder wired directly to an EtherCAT controller allows considerable flexibility with external loop closure and multi-axis drive trains.)

Info

The most basic applications for motion: position and velocity moves. Commanding a motor to go to a specific position or to run at a precise speed.

Info

Slightly more advanced than a position move - the trapezoidal and s-curve moves introduce precise acceleration and deceleration ramps. With a trapezoidal move the ramps are linear, the s-curve move provides for gradual beginning and ending accel/decel (non-linear - often with adjustable "jerk") to allow reduce shock on the load and reduce ringing/bouncing of a dynamic load once the move is complete.

Info

Registration refers to the adjustment of one motion (often a point on a rotating axis) in order to coordinate it with a fixed or moving target. Printing applications often require registration to ensure alignment of print on a page, or when multiple ink colors must be aligned on a printed piece.

Info

Linear interpolation refers to the process of moving 2 or 3 axes in harmony in order to delineate a straight line between two points in 2D or 3D space.

Info

Programmable Limit Switches (PLS) are used to fire outputs (I/O events) at preset positions during a machine cycle. For example a controller might fire an output at a precise location to trigger a labeling machine to apply a label.

Info

Encoder following is used by one axis of motion to match or track the position of a second axis. An external encoder signal might be wired to the motion controller or direictly to the second axis' drive

Info

A flying shear is a cutting device mounted to a precisely controlled trolly which can match the speed of moving material, in order to make a straight cut across the material "on the fly". After the cut, the trolly reciprocates back to it's starting position and readies for another cycle. Flying shears are required in many production processes where it is not possible (or practical) to stop the material flow while making the cut.

Info

Synchronous position phasing is a process that synchronizes a slave axis to a master axis, ensuring that the slave axis reaches the synchronous velocity and position at the same time as the master axis.

Info

Random timing infeed conveyers are used to precisely position conveyed items (products) into desired positions and with proper spacing for subsequent operations. A sequence of 2 or 3 short belts (with product sensors) are used to accelerate or decelerate individual items to achive the desired positioning and spacing. The classic use case is at the entrance to a horizontal wrapping machine, which requires that the incoming products are positioned in sync with the wrapping material, and such that they will not interfere with the sealing/cutting jaws at the exit of the wrapper.

Info

Rotary table applications typically involve indexing one or more workpieces (on a round table) between fixed workstations positioned around the table. The table then pauses at each station, while various process steps are completed. Setup can be as simple as declaring the number of (equally placed) stations in the 360 degree arc - but more complex setup is certainly possible.

Info

In electronic camming, a mechanical cam is replaced by a software profile (called a "cam profile"). These cam profiles are defined as sets of x-y points in a table. The advantage of electronic camming is the ability to change the cam profiles (x-y point sets) quickly and easily without having to make mechanical adjustments, which are time consuming and expensive with a mechanical cam and follower setup.

Info

Rotary knife or shear applications, usually involve a loping motion to enable a single or multi-bladed knife to cut moving material as it passes the knife's location. The rotating knife axis may have to slow-down or speed-up between cuts in order to cut the material at a desired length or at a desired location.

Info

Circular and helical interpolation refer to the process of moving multiple axes in harmony in order to delineate curves in 2D or 3D space.

Info

The process of commanding an axis to exert a specific amount of torque. This control method is exclusive of any position or velocity control and requires an opposing load to prevent runaway. Examples are winding and unwinding applications where one axis of motion may control the speed (of one end) of a material "web", and a second axis (at the other end) runs in torque control mode to maintain constant tension on the target material.

Info

Full closed loop control uses an independent encoder signal (wired to the controller or a particular drive) to close the position (or velocity) loop on a broader scale than the typical motor-mounted-encoder loop. This can be particularly useful for compensating for slippage of material, for instance.

(w/external encoder)

Info

The XMC motion controller has built-in function blocks for several types of robotic control: XYZ, Delta3, LinearDelta3, and T-gantry.

Other controllers may also be able to control robots, they just lack the custom function blocks - so the programming may become very tedious.

Info

The XMC motion controller has built-in interpreter for g-codes and m-codes to facilitate machine tool operations.

For more applications and protocols, include "Motion Controllers" in the Controller Type section (above)

All AutomationDirect PLCs Offer...

- Free Downloadable Software*

- Serial Connectivity

- Ethernet Connectivity

- Modbus RTU Connectivity

- PID Loop Control

- High Speed Counting

- Free 'Two-Day' Shipping

- 45-Day Money-Back Guarantee

- A Great Value!

And all controllers are backed by our award-winning tech support!

For more information about PLCs, download our PLC Handbook eBook.

For more information on our PLC family roadmaps, please read our PLC Statement of Direction.

*The DirectSoft programming software for DirectLogic PLCs offers a FREE downloadable 100-word version; the full version is $395. All other AutomationDirect PLCs (CLICK, Do-More, Productivity Series, & LS PLCs) have totally FREE downloadable programming software. Visit our software downloads page to get started.

- Click criteria on the left to filter PLC families and see features.

- Click criteria on the left to filter PLC families and see features.

- Click criteria on the left to filter PLC families and see features.

- Click criteria on the left to filter PLC families and see features.

- Click criteria on the left to filter PLC families and see features.

- Click criteria on the left to filter PLC families and see features.

- Click criteria on the left to filter PLC families and see features.

- Click criteria on the left to filter PLC families and see features.

- Click criteria on the left to filter PLC families and see features.

- Click criteria on the left to filter PLC families and see features.

Check out our job openings

Free Online PLC Training

FREE Video Tutorials

FREE e-Newsletter

Automation Notebook

Product Literature

White Papers

News, Product and Training Bulletins

E-Books

Safe &

Secure

Safe &

Secure

We accept VISA, MasterCard, Discover, American Express, PayPal or company purchase orders.

Voted #1 mid-sized employer in Atlanta

Check out our

job openings