Cookies are not enabled on your browser.

Cookies are not enabled on your browser.Cookies are required for our site. Please enable cookies in your browser preferences to continue.

- Barcode / RFID / Vision

- Bulk Wire & Cable

- Cables (Terminated)

- Circuit Protection / Fuses / Disconnects

- Communications

- Drives & Soft Starters

- Enclosure Thermal Management & Lights

- Enclosures & Racks

- Field I/O

- HMI (Human Machine Interface)

- Hydraulic Components

- Motion Control

- Motor Controls

- Motors

- Pneumatic Components

- Power Products (Electrical)

- Power Transmission (Mechanical)

- Process Control & Measurement

- Programmable Controllers

- Pushbuttons / Switches / Indicators

- Relays / Timers

- Safety

- Sensors / Encoders

- Stacklights

- Structural Frames / Rails

- Tools & Test Equipment

- Valves

- Water (Potable) Components

- Wire & Cable Management

- Wire & Cable Termination

- Retired Products

Configuration Utilities

- PLC Family Selector

- P1000 PLC Systems

- P2000 PLC Systems

- P3000 PLC Systems

- ProductivityCODESYS

- CLICK PLC Systems

- Do-more® BRX PLC Systems

- LS-Electric® XGB PLC Systems

- Productivity®Open Systems

- Datalogic® Safety Light Curtains

- LS-Electric® Servo Systems

- Nitra® Pneumatic Grippers

- Object Detection (Sensors)

- PAL Controller Configurator

- Precision Gearbox Selector

- Protos X® Field I/O

- Pyrometers Selector

- Quadritalia® Modular Enclosures

- Stellar® Soft Starters

- Stepper System Selector

- SureFrame T-slot Extrusion

- SureMotion® XYZ Gantry

- SureServo2® System Selector

- SureStep® Linear Actuators

- Timing Belts & Pulleys

- Werma® Stacklights

- ZIPLinks

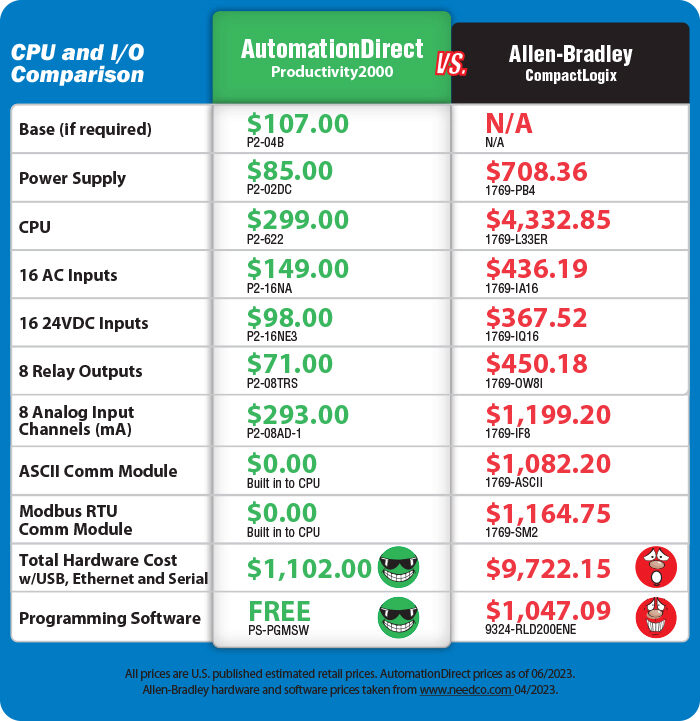

1. Our CPU is under $400.00 . . . Theirs is over $5,000.00!

The Productivity2000 PLC was designed to offer you the lowest cost of ownership in its class. Compare our P2000 PLC CPU (P2-622) to an Allen Bradley CompactLogix PLC CPU (5069-L320ER).

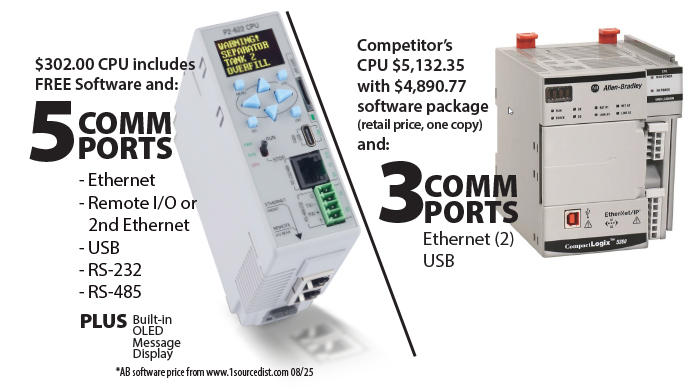

The $5,132.35 (list price) Allen Bradley CPU offers 2MB of user memory, a 32GB SD card slot, three communications ports, and LED CPU status indicators. Of course, you will also need to purchase programming software for the Allen Bradley CPU which can cost thousands.

The $302.00 (everyday price) AutomationDirect P2-622 CPU offers 50MB of built-in memory, a removable micro SD card slot (up to 32GB of data storage and portable program downloads), 5 built-in communications ports, and a high-resolution display with LED status indicators also. Our programming software (developed inhouse) is FREE with no annual licensing or support fees. Download as many copies as you want. On top of that, you'll also get our FREE unlimited phone-in technical support which has received numerous service awards.

Here are a few of the top CPU features:

- Plug-and-play USB programming (no converter cable needed)

- Tag database and program documentation storage on-board the CPU!

- Up to 2 High-speed Ethernet ports for HMI and peer or enterprise networking (no separate Ethernet communications module needed)

- Two serial ports for peripheral device interface or controller networking (no separate serial port or ASCII module needed)

- USB data logging to microSD card right on the CPU

- Programmable 4-line OLED for short message display (including tag data)

- Secure Web Server for fast easy access to your data!

It's all built-in!

2. 5 Built-in communication ports

Imagine the agony of shelling out $5,000.00 or more for an Allen Bradley CompactLogix CPU and having to pay extra to communicate with your existing serial devices. With Productivity2000 you get 5 communications ports with several different protocols standard on the P2-622 CPU.

- RS-232, RS-485, Ethernet, Remote I/O or 2nd Ethernet, and USB (programming) ports built in!

- Modbus RTU, Modbus TCP/IP, EtherNet/IP, MQTTS - included!

- Need more serial connections? No problem, an optional 4-port serial communications module is available if the need arises.

3. Messages displayed vs blinking lights

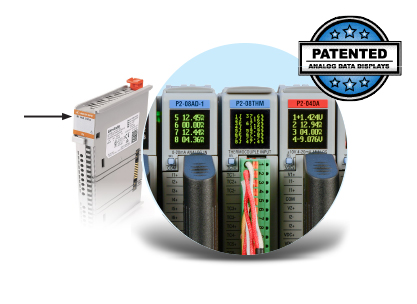

The analog and temperature modules for the P2000 have a patented built-in OLED display on the front of the module. Get accurate process variable data (current, voltage and temperature) as well as system diagnostics in real time, just by reading the display on the Productivity2000 hardware. No tools required! That's much better than the significantly higher priced Allen Bradley temperature (or analog) module's blinking light.

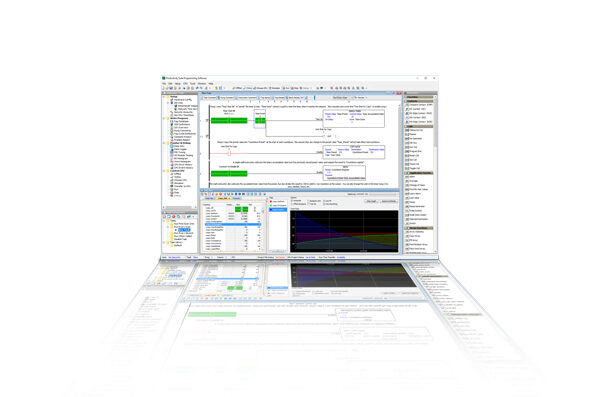

5. Easy PID

Complex operations like PID loops are made effortless with Productivity Suite's easy-to-use instructions. Fill-in-the-blank, function block style configurations save you time and unnecessary headaches. You can configure, tune, and control as many processes as your application requires, without limits, and the integrated auto-tuning functionality will get you up and running in no time.

4. Flexible programming

The Productivity2000 is a tag name based controller which allows for more freedom and flexibility than fixed-memory controllers.

Does your application need 2000 timers but only 15 counters? No problem! Or maybe it needs 4000 real numbers and only 30 integers? No problem!

What about connectivity? No problem there either, with P2000 you can choose to program via the Ethernet port or use the plug-and-play USB Port.

Need to incorporate an HMI/SCADA interface? Easily import your tag database into a SCADA system or C-more HMI for trouble-free development.

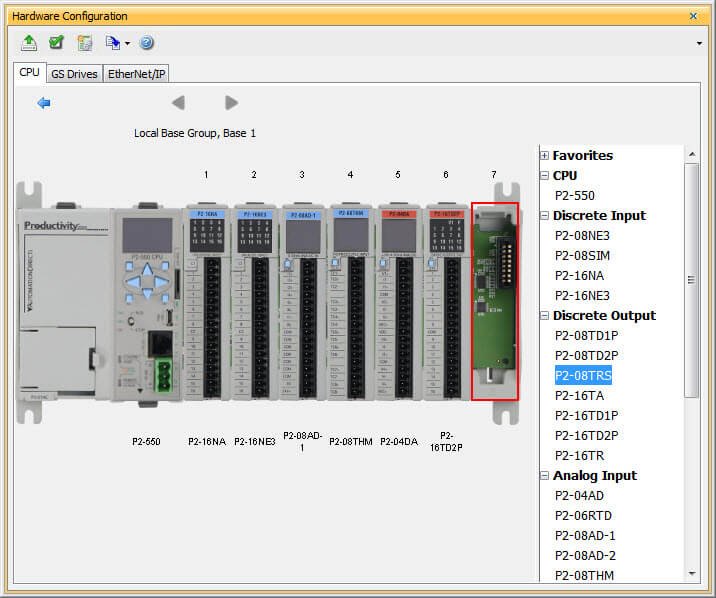

6. Get started in seconds with auto-discovered I/O modules

Simply clip each I/O module into the base and power up. The P2000 will automatically discover the modules and create a realistic picture of your configuration in the free Productivity Suite software. Physical I/O tags will be generated based on each module's position in the base and that's it! You are ready to program with the auto-configured settings just seconds after power-up, or you can reconfigure the setup and assign new tags manually.

8. Hot-swappable I/O - keeps you up and running!

Avoid costly shutdowns, production losses and long start-up operations with Productivity2000 hot-swappable hardware.

That's right, all the I/O modules for the Productivty2000 are hot-swappable! When used appropriately, this capability can save time and help avoid long start-up operations or other down-time related inconveniences. Now that can make you more productive!

Of course, it's up to the system designer to determine if hot-swapping is appropriate and safe for each application.

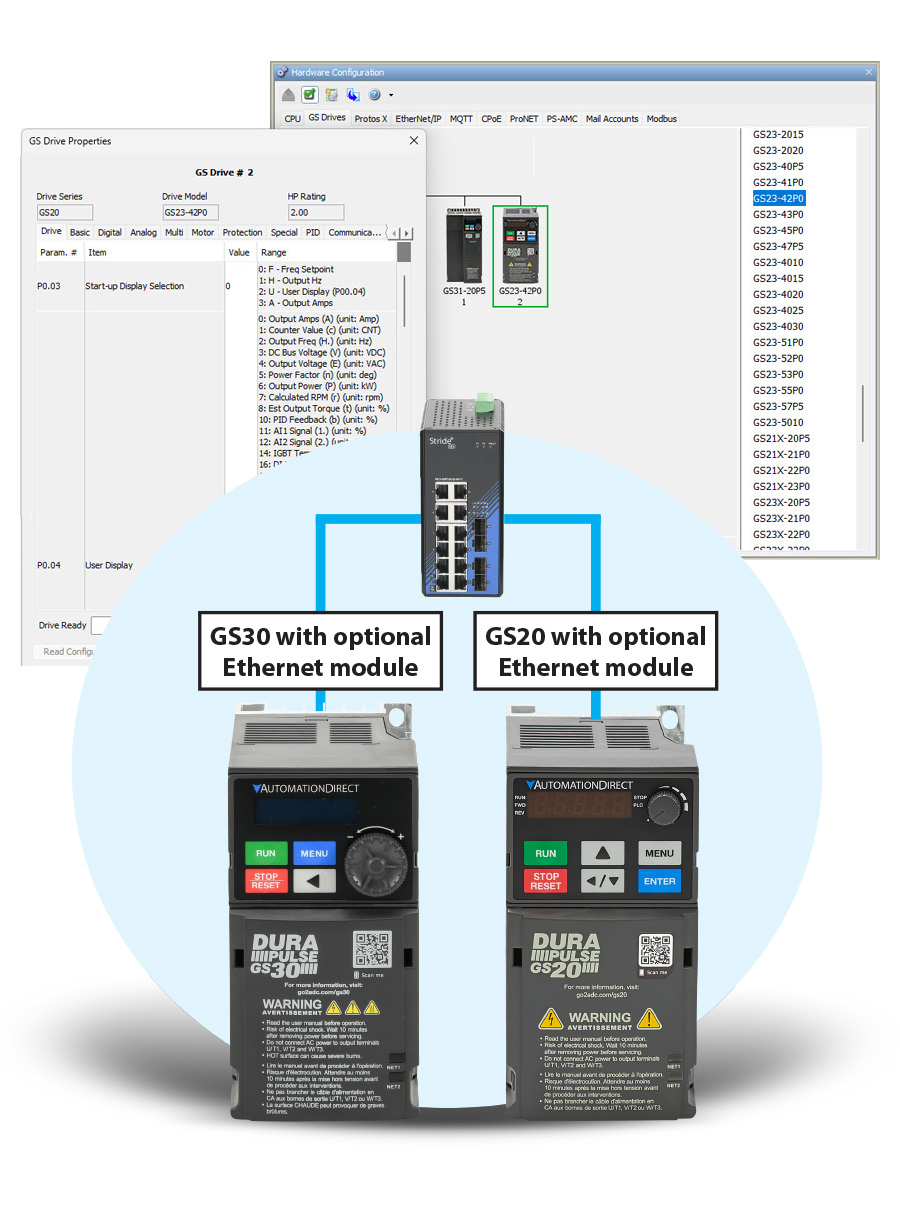

7. VFDs can be set up in seconds

The Productivity2000 programming software is designed to recognize any AutomationDirect GS series drive. Simply connect the drive to the remote I/O port via its Ethernet connection and it is discovered in the Productivity Suite software. And no more searching through drive manuals to find the parameter you need. Each parameter, with description, range, and value, is available in the software. These parameters can be read from, edited, or written to the drive right from the Productivity Suite Hardware Configuration, making initial setup almost too easy! Store all of your drive parameters in the CPU for safekeeping and communicate to your drives with simple read/write instructions in the software. This can save you hours of time.

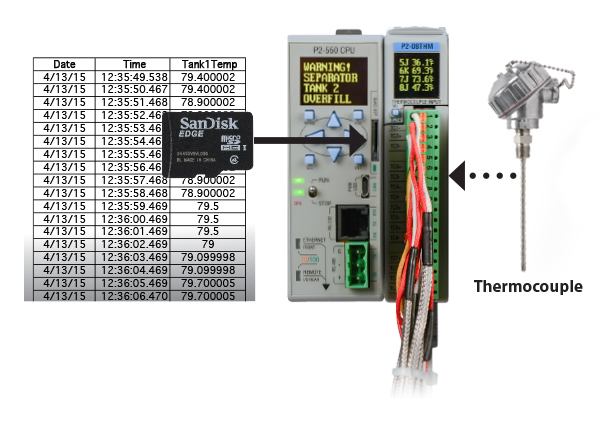

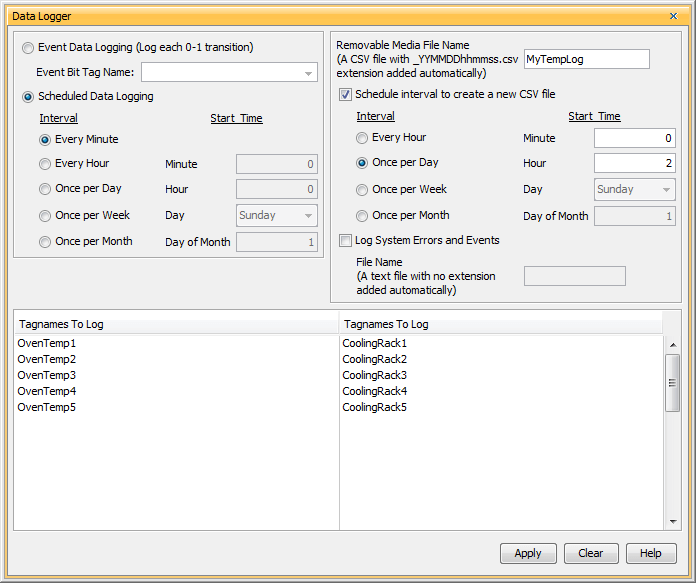

11. Built-in Data Logging

Track up to 64 tags at a time and save the data to the removeable micro-SD card housed in the CPU. Capture up to 32GB of data either periodically (minute, hour, day, week, etc.) or when certain events occur. Scheduling and setup is done with the easy-to-use Data Logger configuration tool in the software (shown below). Log tag data, system errors and system events which can be used to track efficiency and performance, troubleshoot reoccurring or intermittent faults, and predict future breakdowns.

File handling instructions are available in Productivity Suite so you can easily and efficiently access stored data right from the ladder code (P2-622 only).

You can also access your log data securely from any connected web browser via the built-in web server or have the CPU email the most current data logs directly to you with the Send Email instruction!

Flash devices can also be used to upload or download a project to/from a Productivity2000 without having a PC present. This feature is great for updating remotely located PLCs - just send your project on a Flash devices to any factory in the world, and the controller can be updated with the most current project.

While microSD cards are readily available from many sources, AutomationDirect sells this model (Part Number: MICSD-16G), which offers extended vibration and temperature specs for $18.00 . Please understand that AutomationDirect cannot guarantee compatibility with all Flash devices on the market.

10. Slim form factor = DIN rail density

A lot of I/O, in a very small space

- 4-slot base 7-1/2"

- 7-slot base 10-1/2"

- 11-slot base 14-1/2"

- 15-slot base 18-1/2"

Bases: DIN rail or flush mounted

P2-04B: 4-slot base - Holds P2-01AC power supply, CPU and 4 I/O modules. $108.00

P2-07B: 7-slot base - Holds P2-01AC power supply, CPU and 7 I/O modules. $145.00

P2-11B: 11-slot base - Holds P2-01AC power supply, CPU and 11 I/O modules.$195.00

P2-15B: 15-slot base - Holds P2-01AC power supply, CPU and 15 I/O modules.$228.00

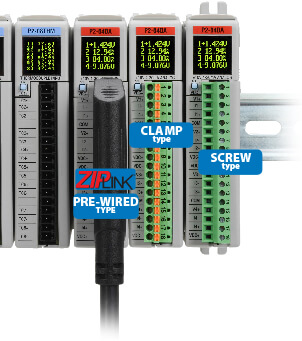

9. Choose the wiring option YOU prefer

Productivity2000 is all about productivity, even down to the wiring. Three wiring options are available to better serve the specific needs of your application. Two terminal blocks; one screw type, and one clamp type are available, as well as our ZIPLink wiring system. Why spend the time wiring each I/O point to a terminal when you can get them prewired? ZIPLink pre-wired cables and terminals not only save you valuable time but also keep your installation clean and efficient, which helps when troubleshooting, and ZIPLinks use half the space at a fraction of the cost of standard terminal blocks. Simply snap the ZIPLink connector to the I/O module, connect your field wiring to the ZIPLink terminal and your wiring job is done.

AutomationDirect strongly recommends the use of ZIPLink cables and wiring modules, which eliminate the need for hand wiring of I/O modules to terminal blocks. In fact, many of the Productivity2000 I/O modules do not include the terminal blocks for direct connection of I/O.

Note: ZIPLinks are available for most, but not all I/O modules.

ZIPLink Module

ZIPLink Pre-Wired

ZIPLink Pigtail Cable

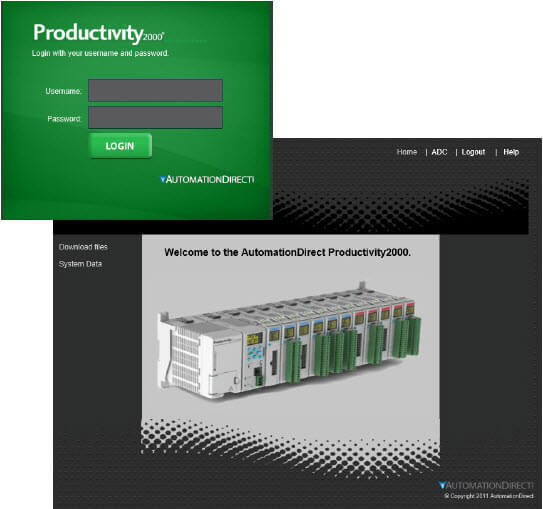

12. Web Server

Access data files and system tags remotely from any web browser, anywhere! The secure password protected login prevents unwanted access and keeps data safe. With the CPU's integrated Web Server you can access Data Logger files stored on an installed flash device (optional) as well as monitor system status via the (read-only) System Tags.

Secure Login:

Set your Username & Password to prevent unwanted access

Main Screen:

Once you have accessed the internal webpages, select the Download files (user-defined data logging files) or the list of System data categories for viewing.

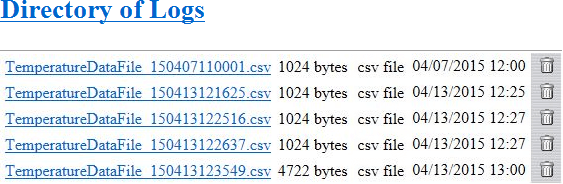

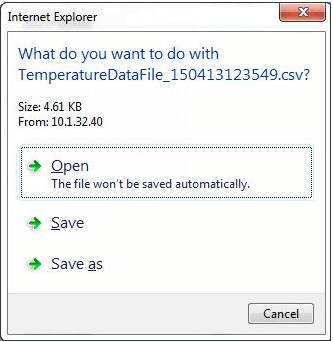

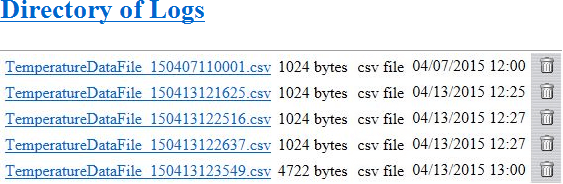

Accessing Data Files:

Data log files are presented in a directory based on the file names and the frequency of archive you select when configuring the Data Logger. From the Web browser you can easily manage these files. You have the options of viewing, saving or deleting the files from the flash device. Also, when you select the "Log System Errors" in the Data Logger, you gain access to the Error log file.

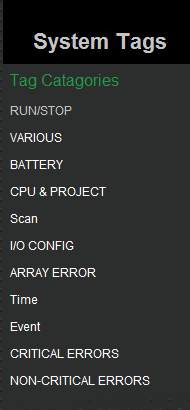

Accessing System Tags:

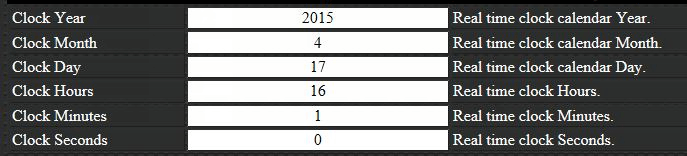

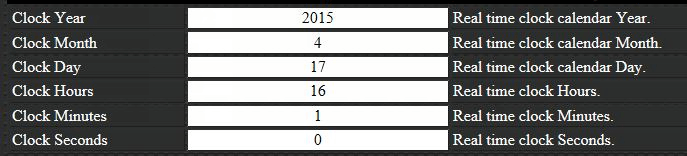

When you select the System Data option from the Web server main screen you have access to all read only System tags in the CPU. These are divided into the categories shown at right:

This example below shows the CPU Date & Time tags:

Check out our job openings

Free Online PLC Training

FREE Video Tutorials

FREE e-Newsletter

Automation Notebook

Product Literature

White Papers

News, Product and Training Bulletins

E-Books

Safe &

Secure

Safe &

Secure

We accept VISA, MasterCard, Discover, American Express, PayPal or company purchase orders.

Voted #1 mid-sized employer in Atlanta

Check out our

job openings

Loading...

Loading...