Cookies are not enabled on your browser.

Cookies are not enabled on your browser.Cookies are required for our site. Please enable cookies in your browser preferences to continue.

- Barcode / RFID / Vision

- Bulk Wire & Cable

- Cables (Terminated)

- Circuit Protection / Fuses / Disconnects

- Communications

- Drives & Soft Starters

- Enclosure Thermal Management & Lights

- Enclosures & Racks

- Field I/O

- HMI (Human Machine Interface)

- Hydraulic Components

- Motion Control

- Motor Controls

- Motors

- Pneumatic Components

- Power Products (Electrical)

- Power Transmission (Mechanical)

- Process Control & Measurement

- Programmable Controllers

- Pushbuttons / Switches / Indicators

- Relays / Timers

- Safety

- Sensors / Encoders

- Stacklights

- Structural Frames / Rails

- Tools & Test Equipment

- Valves

- Water (Potable) Components

- Wire & Cable Management

- Wire & Cable Termination

- Retired Products

Configuration Utilities

- PLC Family Selector

- P1000 PLC Systems

- P2000 PLC Systems

- P3000 PLC Systems

- ProductivityCODESYS

- CLICK PLC Systems

- Do-more® BRX PLC Systems

- LS-Electric® XGB PLC Systems

- Productivity®Open Systems

- Datalogic® Safety Light Curtains

- LS-Electric® Servo Systems

- Nitra® Pneumatic Grippers

- Object Detection (Sensors)

- PAL Controller Configurator

- Precision Gearbox Selector

- Protos X® Field I/O

- Pyrometers Selector

- Quadritalia® Modular Enclosures

- Stellar® Soft Starters

- Stepper System Selector

- SureFrame T-slot Extrusion

- SureMotion® XYZ Gantry

- SureServo2® System Selector

- SureStep® Linear Actuators

- Timing Belts & Pulleys

- Werma® Stacklights

- ZIPLinks

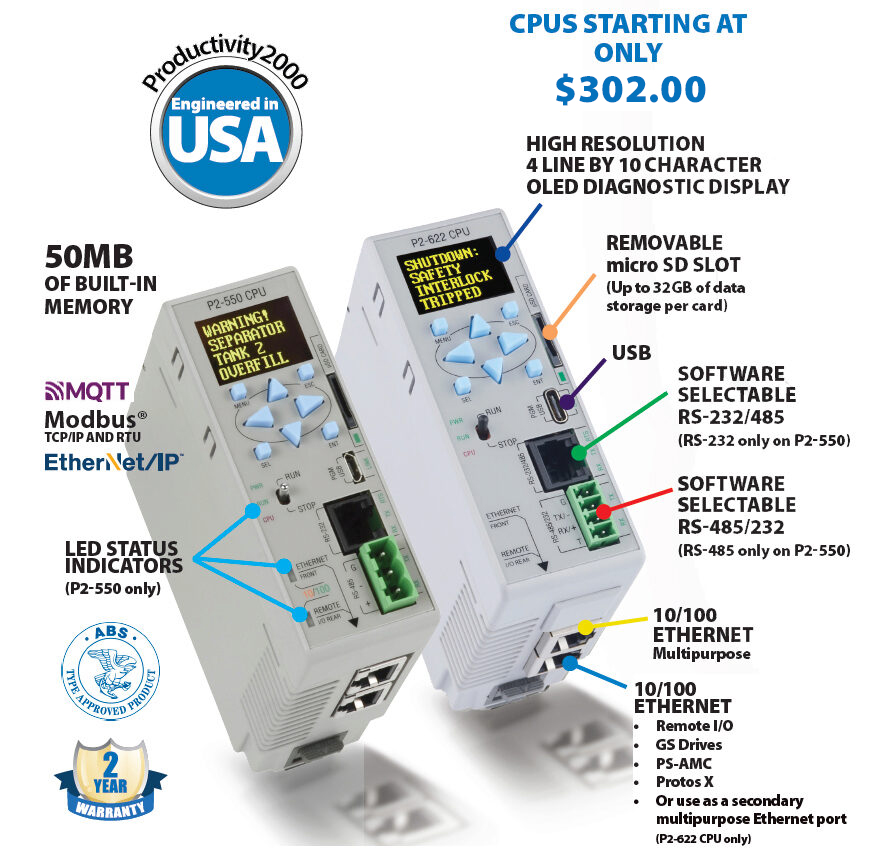

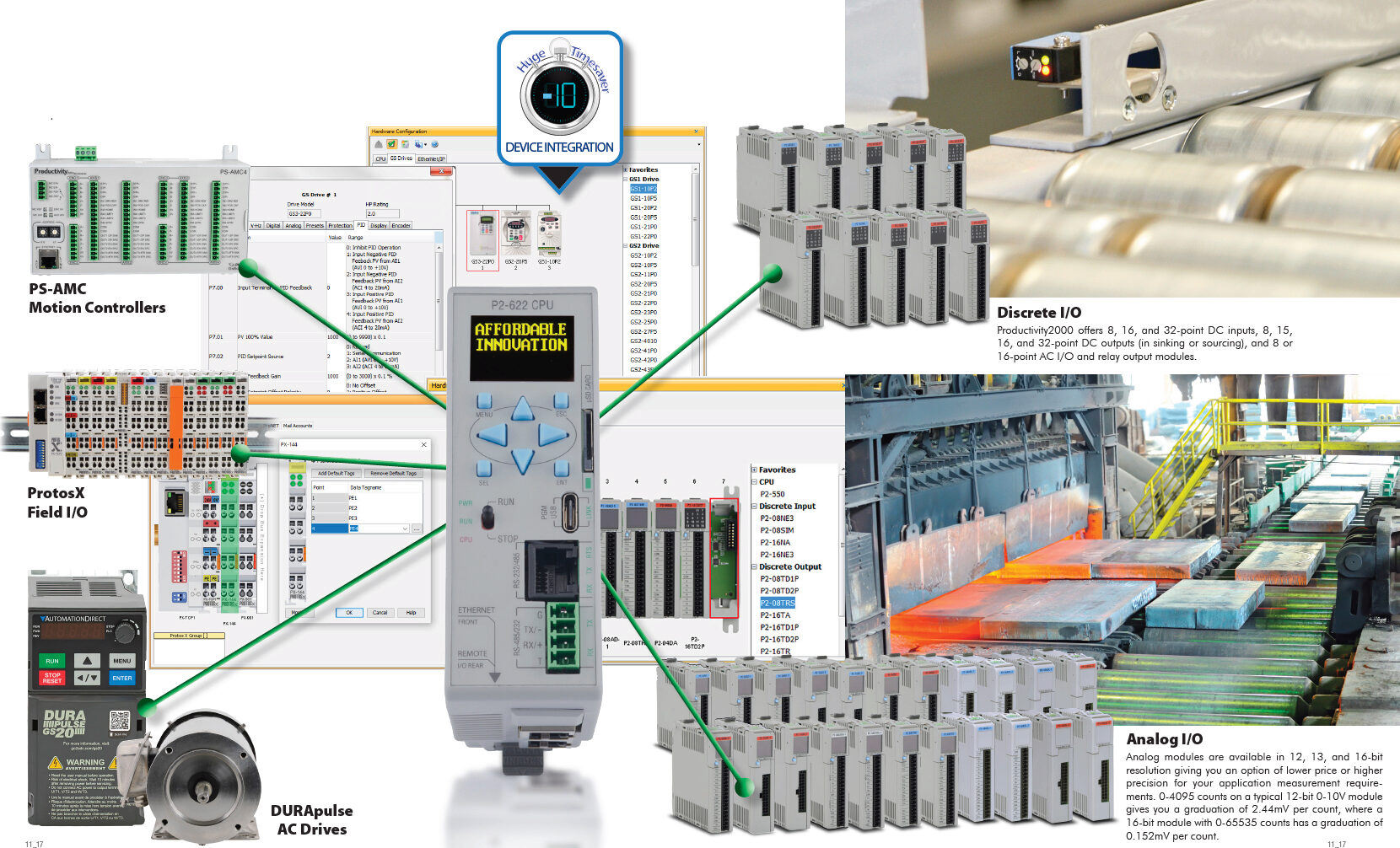

Low-cost hardware, small in size, rich on features

Powerful High-performance CPUs

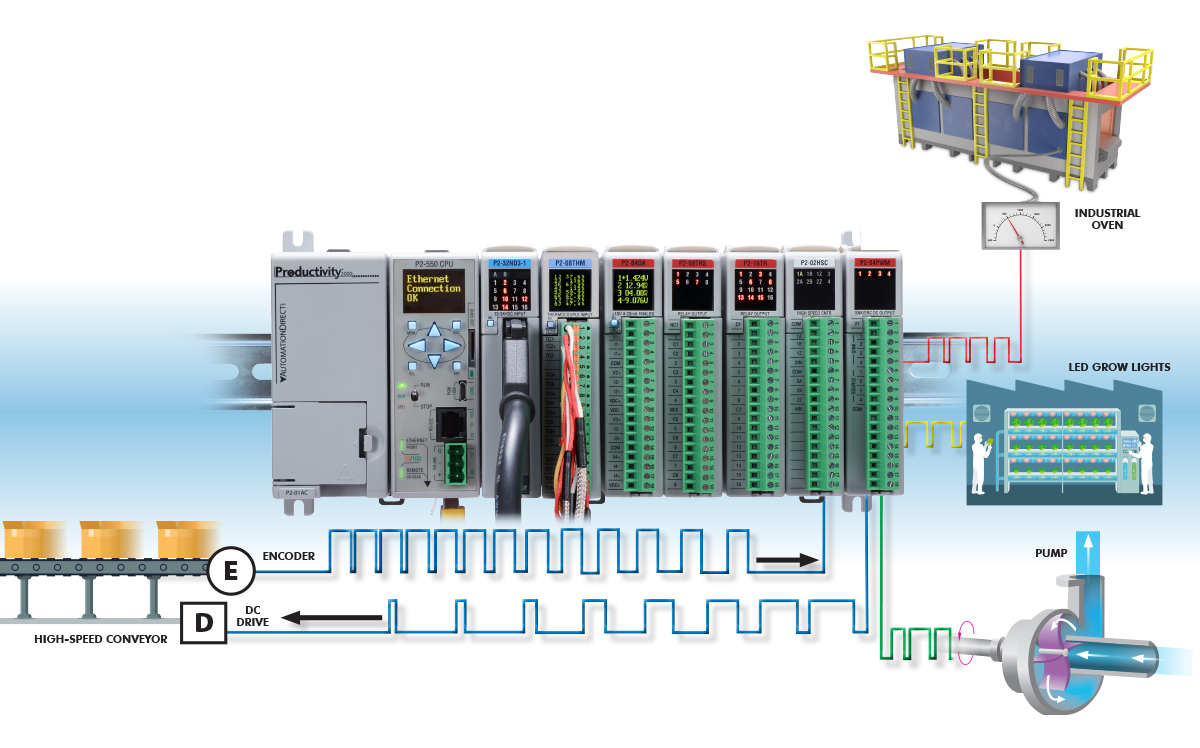

The 50MB of memory and fast scan times are just for starters - these CPUs do the work of at least four or five pieces of hardware. With five built-in communications ports, these processors do the usual CPU stuff like storing and running the program, plus they offer:

- Plug-and-play USB programming

- A high-speed Ethernet port for HMI and peer-to-peer or business system networking (no Ethernet communications module needed)

- Seamless integration with PS-AMC motion controllers, GS series drives, and Protos X field I/O using Remote I/O port

- P2-622 CPU allows Remote I/O port to also be used as a secondary multipurpose Ethernet port

- Support for EtherNet/IP devices

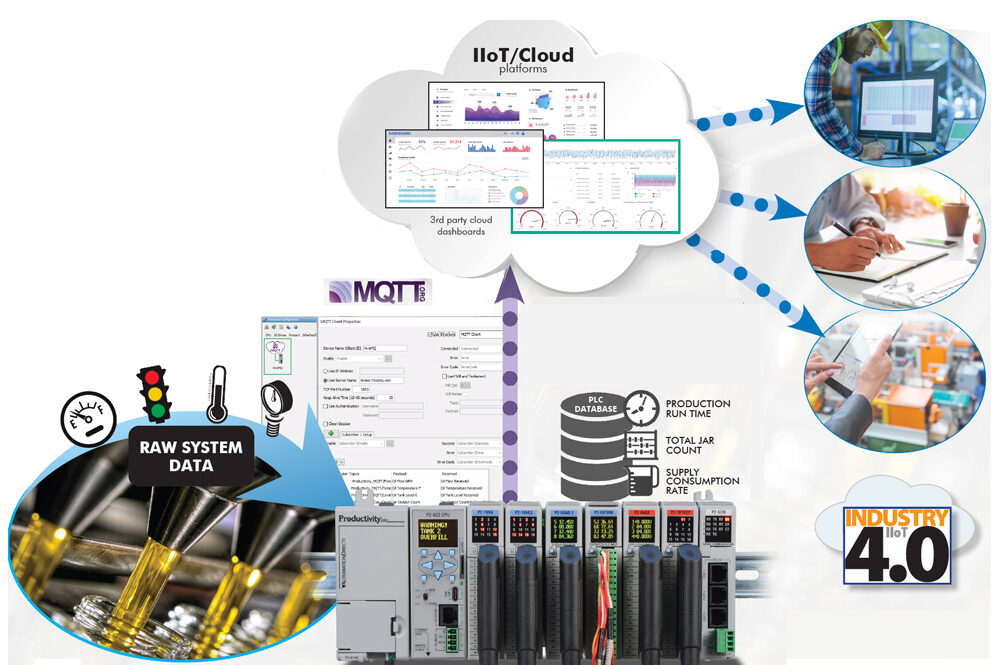

- IIoT-ready installations with MQTT protocol support for cloud based communication; P2-622 CPU also supports MQTTS (encrypted) protocol

- Two serial ports for peripheral device interfacing or controller networking; P2-622 serial ports are software selectable for RS-232 or RS-485

- micro SD data logging right from the CPU

- ABS certifications for marine applications (P2-550 only)

Remote I/O Modules

Control applications are often broken out into several different machines or sub-systems that all communicate back to a primary PLC CPU. To connect each I/O point from these remote devices to the main CPU would take numerous, extensive wire runs. The Productivity2000 remote I/O modules can be installed at a remote location and communicate all I/O signals back to the main PLC using a single Ethernet communication cable. Distributing I/O this way saves installation time, wiring costs, troubleshooting/wire tracing headaches, and makes it much easier if/when remote devices need wiring modifications or need to be relocated.

- 10/100 Mbps Ethernet connection for signal transmission

- Up to 8 remote I/O groups allowed with every CPU (using Remote I/O Ethernet Port)

- Up to 15 I/O modules per remote group (depending on power supply)

- Using P2-RS remote I/O modules, 3,840 additional I/O points are possible (8 remote groups, 15 slots each, 32-point I/O)

- Using the lower cost P1-RX remote I/O module, 1,024 additional I/O points are possible (8 remote groups, 8 slots each, 16-point I/O)

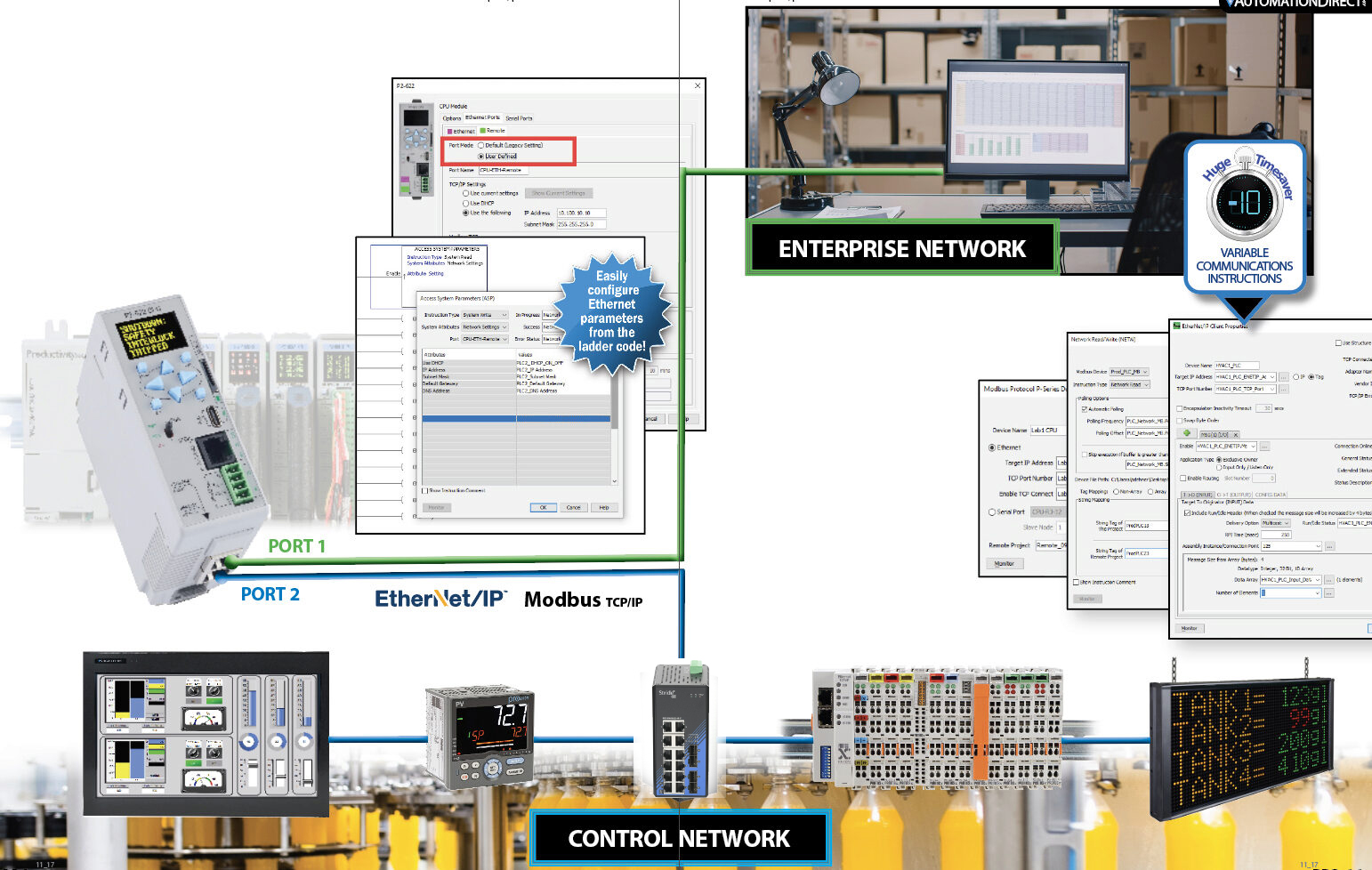

Practical Ethernet communication

5 built-in communications ports and multiple protocols including MQTT and EtherNet/IP

The Productivity2000 CPUs come standard with 5 built-in communication ports including Ethernet, USB, and serial, and support for several communication protocols (MQTT(S), EtherNet/IP, Modbus TCP, and Modbus RTU) all for around $300. That's 1/10th the cost of some competitors!

Built-in Ethernet on the CPU has got you covered!

Productivity2000 CPUs come with two of the top industrial Ethernet protocols in our market. Modbus TCP and EtherNet/IP are a must for any up-to-date control system. MQTT is also supported which is fast becoming an industry requirement as the IIoT and machine-to-cloud connections become more and more prevalent. The P2-622 CPU also supports the secure MQTTS protocol for those applications requiring a TLS connection.

Two Ethernet ports on bottom of CPU:

Front: 10/100Mbps multipurpose Ethernet port for program-ming, monitoring, firmware upgrades, and the following client/server connections:

- 32 Modbus TCP Client connections (CPU Master)

- 16 Modbus TCP Server connections (CPU Slave)

- 32 EtherNet/IP Scanners (CPU Master)

- 4 EtherNet/IP Adapters (CPU Slave)

- 4 cloud connections using MQTT(S)

A total of 128 EtherNet/IP connections and over 5,000 EtherNet/IP messages per second! And unlike many controllers, the Productivity series CPUs support both Explicit and Implicit (I/O) messaging for greater functionality.

The Productivity2000 also provides a Custom Protocol over Ethernet (CPE) option which gives the user the ability to create their own communication protocol between the Productivity series CPU and a 3rd party Ethernet device via TCP or UDP.

The ProNET feature allows any P-series CPU to seamlessly share data by publishing or subscribing to data from other CPUs. Up to 32 publishers and/or subscribers are allowed per CPU.

Rear: 10/100Mbps Ethernet port supports up to 16 GS series variable frequency drive connections, 4 PS-AMC motion controllers, 8 remote I/O bases (using P2-RS and/or P1-RX modules) and 4 Protos X field I/O racks. GS drive parameters, PS-AMC and Protos X field I/O configura-tions are easily modified within ProductivitySuite and saved with the PLC project. P2-622 CPU also allows this port to be configured as an additional multipurpose Ethernet port for applications with multiple networks.

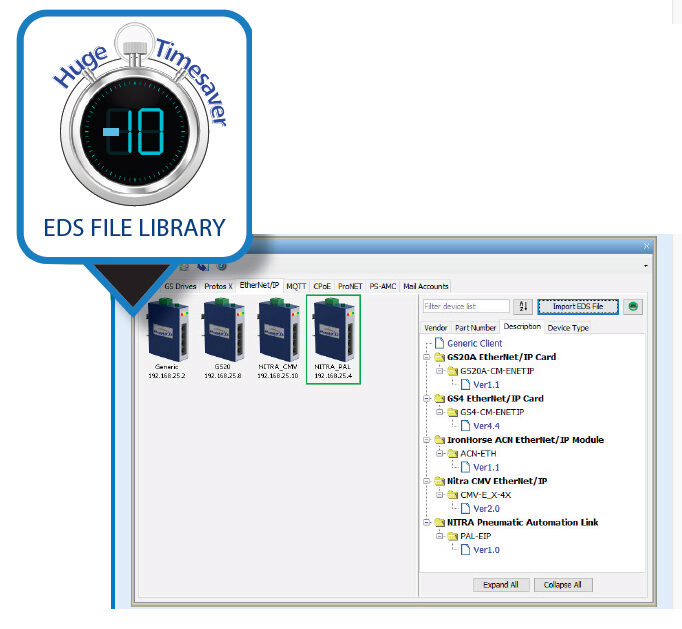

Productivity Suite makes communicating with EtherNet/IP devices a snap.

- Scanner and adapter supported

- Implicit application types supported include input-only and listen-only

- EDS file configuration presented in an easy-to-use drop-down menu

- Ability to select multiple connection options from an EDS file which simplifies configuration

- The EDS file library offers an easy way to upload, store, and manage your EDS files

- AutomationDirect.com EtherNet/IP EDS files are preloaded in the library for convenience

EDS Library

The EDS file library offers a powerful way to organize and sort your EDS files - automatically group by device type or vendor and manage versions. AutomationDirect.com EtherNet/IP EDS files come already installed for added convenience.

Versatile Ethernet that adjusts to your needs!

The P2-622 CPU has several features that provide supreme versatility with Ethernet communication. This CPU can be configured to operate with two multipurpose Ethernet ports. Simply check the "User Defined" selection in the CPU Port 2 configuration to set up the Remote I/O port for multipurpose use. Then configure the remaining settings for the additional port or you can access the network settings anytime using the ASP instruction from the ladder code.

PORT 1: This multipurpose Ethernet port can be used with numerous networks, for example, use this port to connect to high-level production analysis systems, inventory management software, etc.

PORT 2: Configure this port (normally reserved for remote I/O) as an additional multipurpose Ethernet port and gather data from factory-floor process controllers, control-room HMIs, etc. In this scenario, the P2-622 CPU, with its configurable Port 2, can act as an inexpensive data bridge, transferring vital process data from the factory floor to upper-level enterprise systems.

Communicate on the fly

The Variable Communications Instructions (VCIs) in the Productivity Suite software allow tags to be used for almost every field so you can communicate with virtually unlimited devices using a single instruction. Simply alter tag values on the fly to switch from one MQTT broker the the next, or write new parameters to several VFDs without having to code one instruction for each. VCIs work with Modbus comms, serial comms, Productivity-to-Productivity network comms, and other communication configurations/instructions (Email, EtherNet/IP, and MQTT).

Use case 1: Dynamically modify the IP address (TCP) or slave node (RTU) to target multiple devices with the same configuration/instruction.

Use case 2: A single EtherNet/IP configuration can target multiple devices by dynamically modifying target IP address and message size in ladder.

Use case 3: A single MQTT client, with max. 30 topic fields, can send and/or receive data for thousands of different topics and even target different brokers (servers) by dynamically modifying topic string tags and broker connection parameters in ladder.

Easy cloud communication

Industrial machines/systems are more connected than ever before, whether internally with upstream IT management systems or externally with remote support personnel, modern-day plant-floor machines/systems need to communicate to a variety of networks. Cloud networking, with its computing and data storage platforms, has also become a viable solution for analyzing and accessing production data from anywhere at anytime. Using powerful cloud platforms such as IBM Watson® to analyze production-floor data can provide better process efficiency, improved plant-wide resource management, and less operational downtime.

But how does data from a simple level switch on a tank get to the cloud? With Productivity PLCs, it's easy! Productivity PLCs have the communication capabilities and processing power needed to not only control plant-floor machines but gather valuable data from them, package it, and send it on to higher level analysis systems.

Mulitple data gathering options

Productivity PLCs offer many I/O options to choose from for your system data collection. I/O modules, available in analog, discrete, high-speed, relay, and temperature versions, allow you to create the custom I/O configurations your application needs. And with Modbus RTU, Modbus TCP and EtherNet/IP protocol support, Productivity2000 PLCs can easily gather raw data from a variety of VFDs, sensors, switches, encoders, pilot devices, or almost any other control component your system may have.

The MQTT protocol has become the frontrunner for many machine-to-machine (M2M) and IIoT/cloud networking applications, due to its lightweight overhead and reduced bandwidth consumption. Productivity PLCs support MQTT communication (P2-622 CPU also supports the MQTTS protocol) and with fill-in-the-blank MQTT messaging configurations, delivering vital data to advanced cloud computing platforms is easy.

Compatible with MQTT brokers and cloud platforms/services including:

- IBM Watson®

- Mosquitton®

- HiveMQn®

- Thingsboardn®

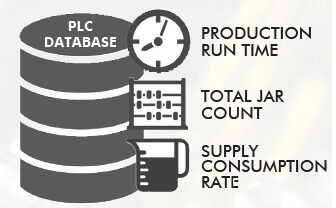

Refining data into something meaningful

The Productivity Suite programming software makes refining raw data into a meaningful metric a cinch. With a multitude of simple-to-use instructions combined with the computing power of a Productivity CPU, Productivity Suite can easily transform a raw process signal, like 4-20mA, into a consumption rate, a production throughput, an energy efficiency score, a rejection percentage, or any other metric that's vital to you.

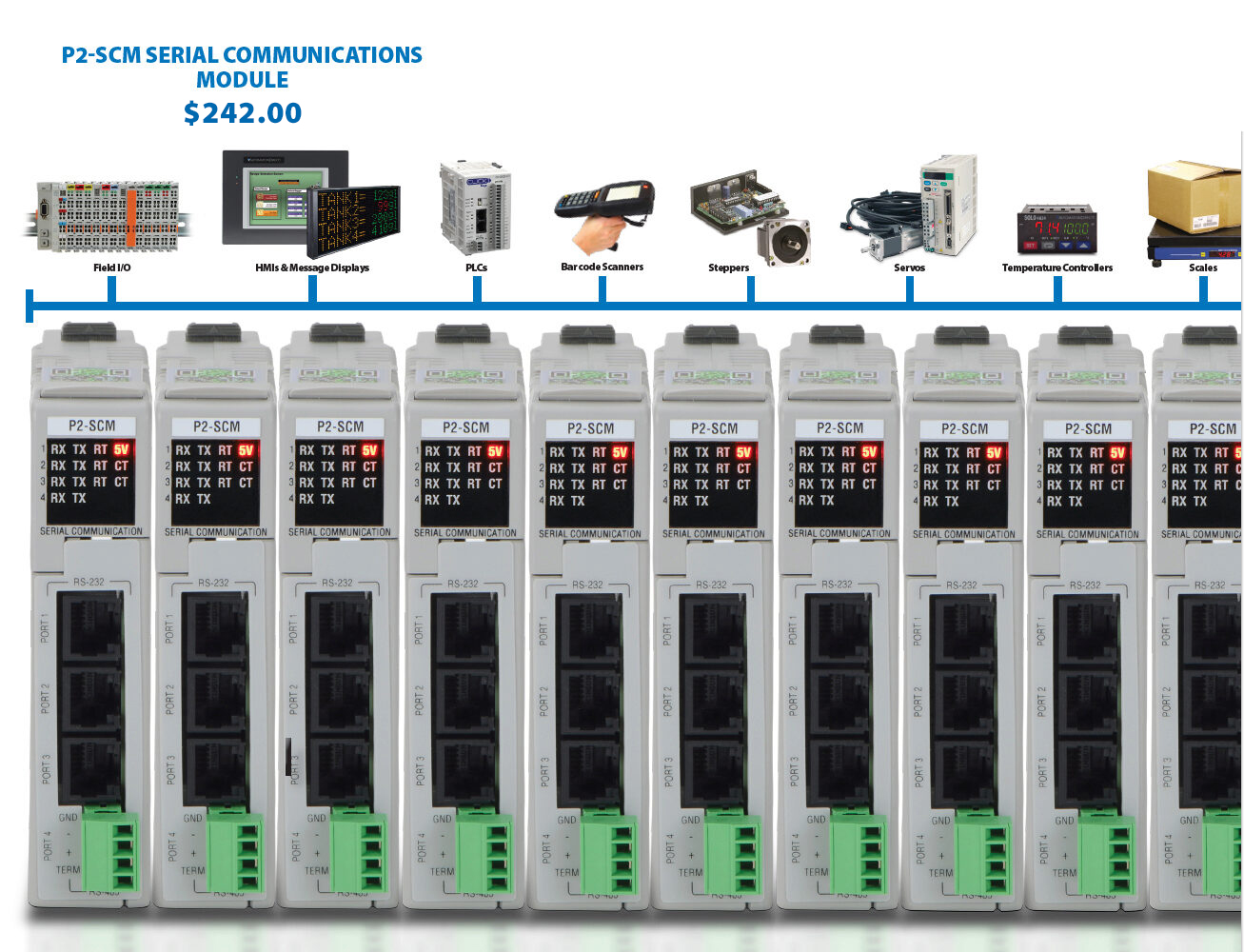

Inexpensive serial communication

Got serial? Get connected for less with the Productivity2000

Serial communication has been around for decades and to this day is still a viable communication method. Although Ethernet communication has become the top choice for industrial automation, serial communication is still very reliable and inexpensive to design into a device.

For serial connections, Productivity CPUs provide two serial communication ports:

- P2-550: (1) RJ12 (6P6C) port for RS-232 devices and (1) 3-wire screw terminal for RS-485 multi-drop devices

- P2-622: (1) RJ12 (6P6C) port that is software configurable for RS-232 or RS-485 devices and (1) software configurable 4-wire screw terminal for RS-485 or RS-232 multi-drop devices

- These ports provide Modbus RTU Master/Slave capability, ASCII In and Out capability and Custom Protocol over serial capability

- RS-485 ports can support up to 50 multi-drop devices (more if repeater is added to network)

Up to 62 serial ports per system!

RS-232 is a point-to-point protocol, meaning that you're typically talking to one device from that port. In applications with many serial devices talking to the control system through RS-232 communication, a lot of serial ports will be consumed very quickly.

With the Productivity2000 you can have up to 15 of the 4-port P2-SCM serial communications modules per system. Each module has (3) RS-232 ports and (1) multi-drop RS-485 port. This gives you an additional 60 serial ports, 62 total with the CPU, for any given system or application.

Serial protocols that every system should have...

The Productivity2000 supports Modbus RTU Master/Slave connections, full-duplex ASCII and even a full-duplex Custom protocol.

- Modbus RTU is by far the #1 serial protocol in our industry. Supporting both Master and Slave Modbus RTU connections allows the P2000 to communicate with numerous devices such as operator interface panels and message displays, drives, temperature and process controllers, steppers, servos, and many more.

- Full-duplex ASCII is very common and is used in devices that send and receive non-sequence string data. Bar code scanners, weight scales, and printers are a few devices that regularly use ASCII communication.

- The full-duplex Custom protocol capability allows for instances where the end device communicates with a protocol that is uncommon. Using the CPI/CPO instruction in ladder, you can manually configure and send/receive protocol packets to/from the controller.

Field-friendly features ... FOR LESS!

Troubleshoot the easy way

The Productivity2000 analog modules include patented high-contrast OLEDs which make it simple to view analog values without extra equipment. These ultra-clear displays allow you to read up to 8 channels of analog values, making troubleshooting easier than ever before. Voltage, current, temperature, and even fault conditions are displayed for your convenience and eliminate the need to disconnect signal wires in order to get a reading with a meter.

Configurable hot swappable I/O

Don't lose production for simple I/O module changes. The P2000 system can be configured to allow the CPU to remain in the RUN mode without the selected I/O modules installed. Choose the "Enable all Hot Swap" option in the software to allow any module to be removed or configure each module separately.

With the Productivity2000 you can have up to 15 of the 4-port P2-SCM serial communications modules per system. Each module has (3) RS-232 ports and (1) multi-drop RS-485 port. This gives you an additional 60 serial ports, 62 total with the CPU, for any given system or application.

ZIPLink pre-wired solutions

The Productivity2000 modules have multiple wiring options available. Standard terminal blocks are available in both screw and spring clamp styles. Our ZIPLink pre-wired cables and connector modules are available for all modules, excluding the Thermocouple and RTD temperature modules which require a specific type of wire. ZIPLinks not only provide tremendous time savings when panel building but can also provide fused isolation from field devices, clean wireways with easy, field-traceable connections, and confidence that your panel wiring is correct.

Keep the UP in STARTUP...

The Productivity2000 system has many features built in to help with field installations and startups as well as on-the-job modifications.

Save valuable time with CPU OLED message displays

The standard OLED message display on the CPU gives you instant status on your controller and can be configured for system fault detection. CPU event and error messages are automatically displayed and you can use the LCD instruction to send custom messages from ladder code based on the conditions you specify. Use the keypad to navigate the display menu and view the controller's current firmware revision, Ethernet IP address, system configuration or error history. This valuable data is easily accessible in the field which can greatly reduce downtime or keep your startup on schedule.

Convenient QR codes

When your system is down and the pressure is on, don't waste precious time searching for needed documents. Get wiring diagrams, installation instructions, and specifications simply by scanning the drop-down QR code tab on each Productivity2000 I/O module.

Utmost integration for in-a-flash-configuration

Productivity series controllers are designed for easy hardware configurations and provide automatic integration of many industrial automation devices. Any I/O module installed in the local or remote base will be automatically discovered by the software. Same goes for any Productivity motion controller, any AutomationDirect AC drive, or any Protos X field I/O system. This auto-discovery process eliminates configuration headaches and allows you to bypass the time needed to configure each hardware component.

(click to enlarge)

From simple to sophisticated, we've got an affordable motion control solution for you

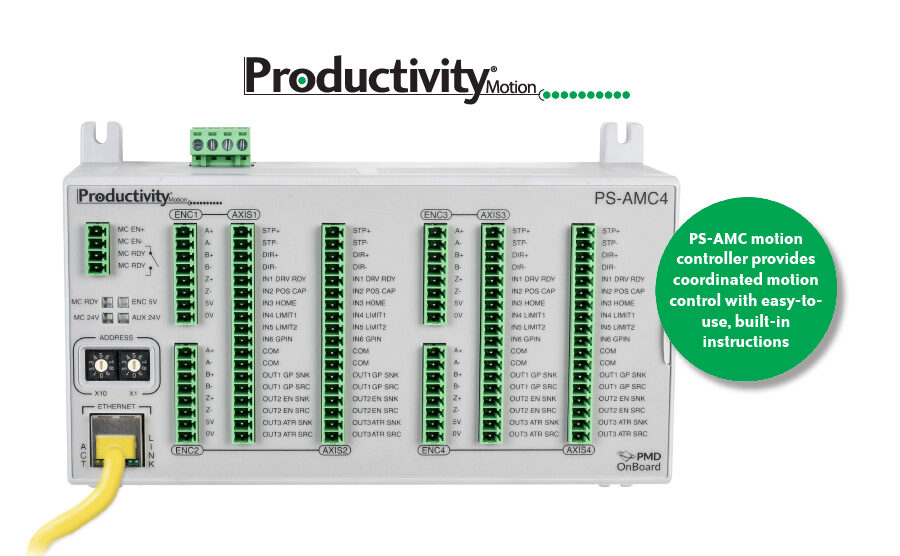

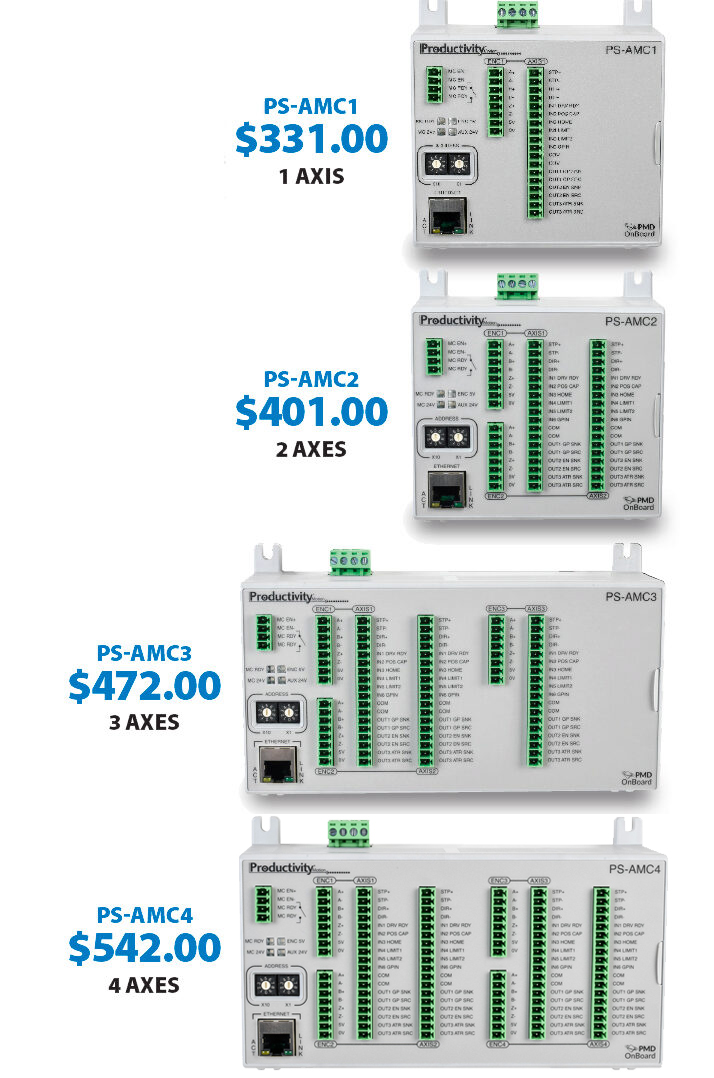

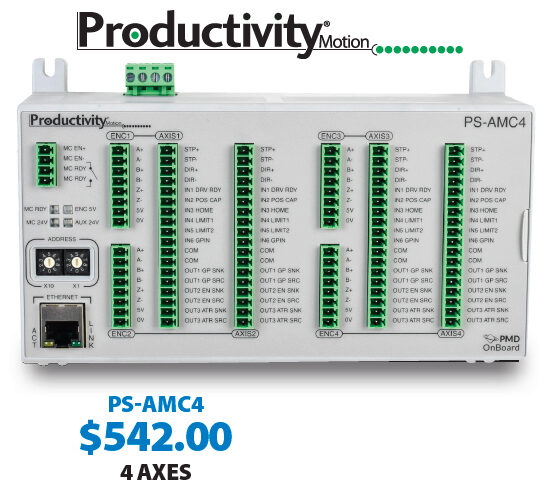

PS-AMC Enhanced Motion Controller

Starting at only $331.00

The PS-AMC motion controller is an ideal choice for low-cost coordinated motion that's easy to use and reliable. Designed to work effortlessly with the Productivity family of CPUs, the AMC provides accurate, synchronized, motion control on up to four axes per module for a very attractive price.

Use the PS-AMC with select Productivity series CPUs for low cost, coordinated motion control in any application

- Flying cut-off systems

- Press feeds

- In-line bottle filling

- Auger fillers

- Label applicators

- Smart conveyor systems (random timing infeeds)

- Rotary tables

- Vertical-form-fill-seal

- Case erectors/ packers

- Cut to length systems

- High-speed mail sorting

- Web/film handling

- Boring/drilling/tapping

- Coil winding

- Wrapping

- Thermo-formers

- Rotary knives

- And many more...

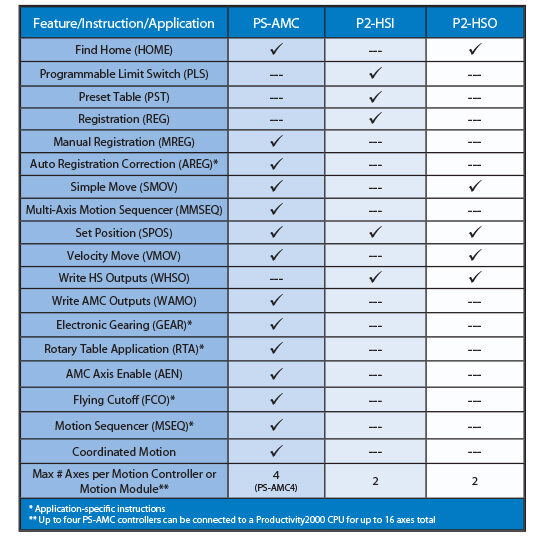

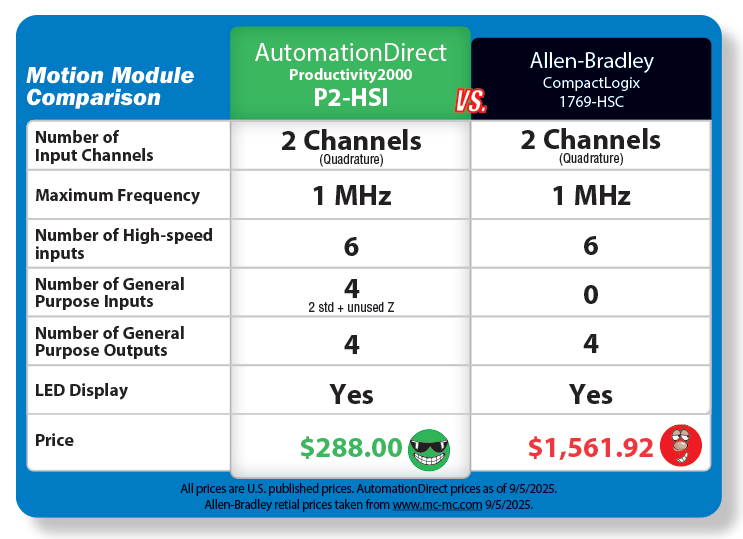

P2-HSI / P2-HSO Modules

Priced at $288.00

If you need to perform simple motion commands like homing routines, set position, preset tables, etc. on up to 2 axes per module, then the P2-HSI and P2-HSO modules may be all you need. These modules slide right into any open slot in any local or remote rack, easily adding low-cost basic motion control to your Productivity2000 system.

Multi-axis motion control that's accurate and affordable

The PS-AMC motion controller is an ideal solution for motion control applications requiring several independent axes of motion and/or coordinated motion between some or all axes. Available in one to four axes models, the PS-AMC provides highly accurate positioning using encoder fed control (one encoder per axis). Used in conjunction with select Productivity CPUs and programmed with the FREE Productivity Suite software, the AMC can supply up to 1MHz of pulse-train command signals to servo or stepper drives for extremely responsive movements in any application.

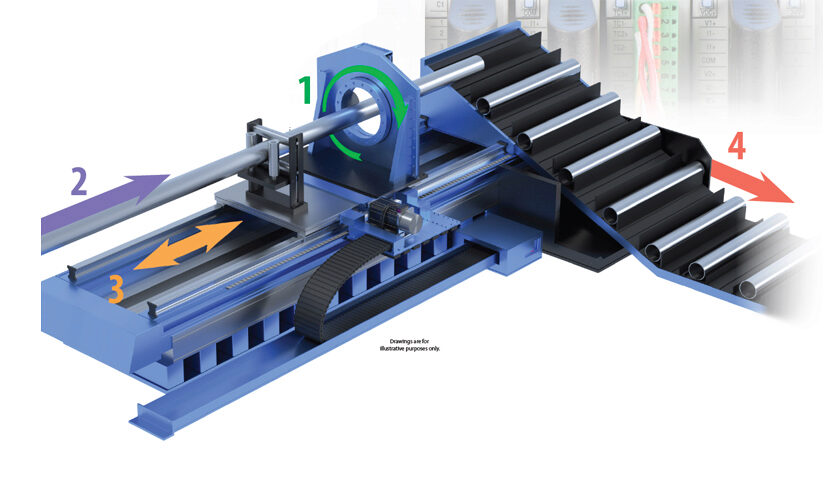

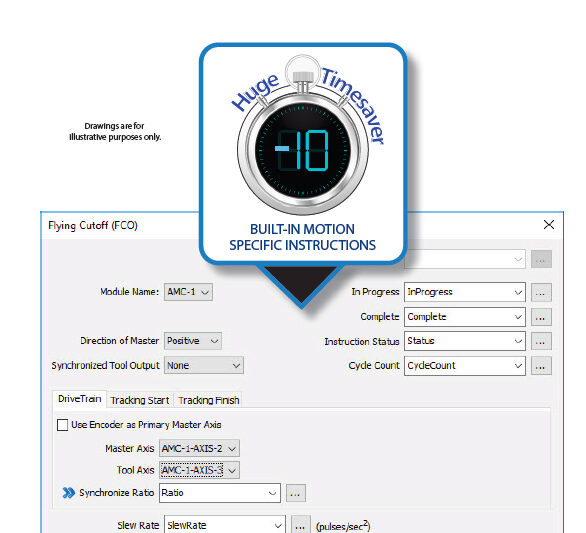

Flying cut-off application

The primary function of a flying cut-off system is to synchronize the speed of a servo-driven carriage, on which a cutting mechanism is mounted, with the speed of a continuously fed material to make a perpendicular cut without stopping the feed. These applications are used where it isn't practical to stop and start a continuous production operation. The flying cut-off shown above employs four axes of motion, a rotating pipe cutter 1, a continuous pipe infeed system 2, carriage positioning drive 3, and outbound conveyor 4. With the PS-AMC4, all four of these axes can be easily controlled and synchronized within the same controller, and it's only $542.00

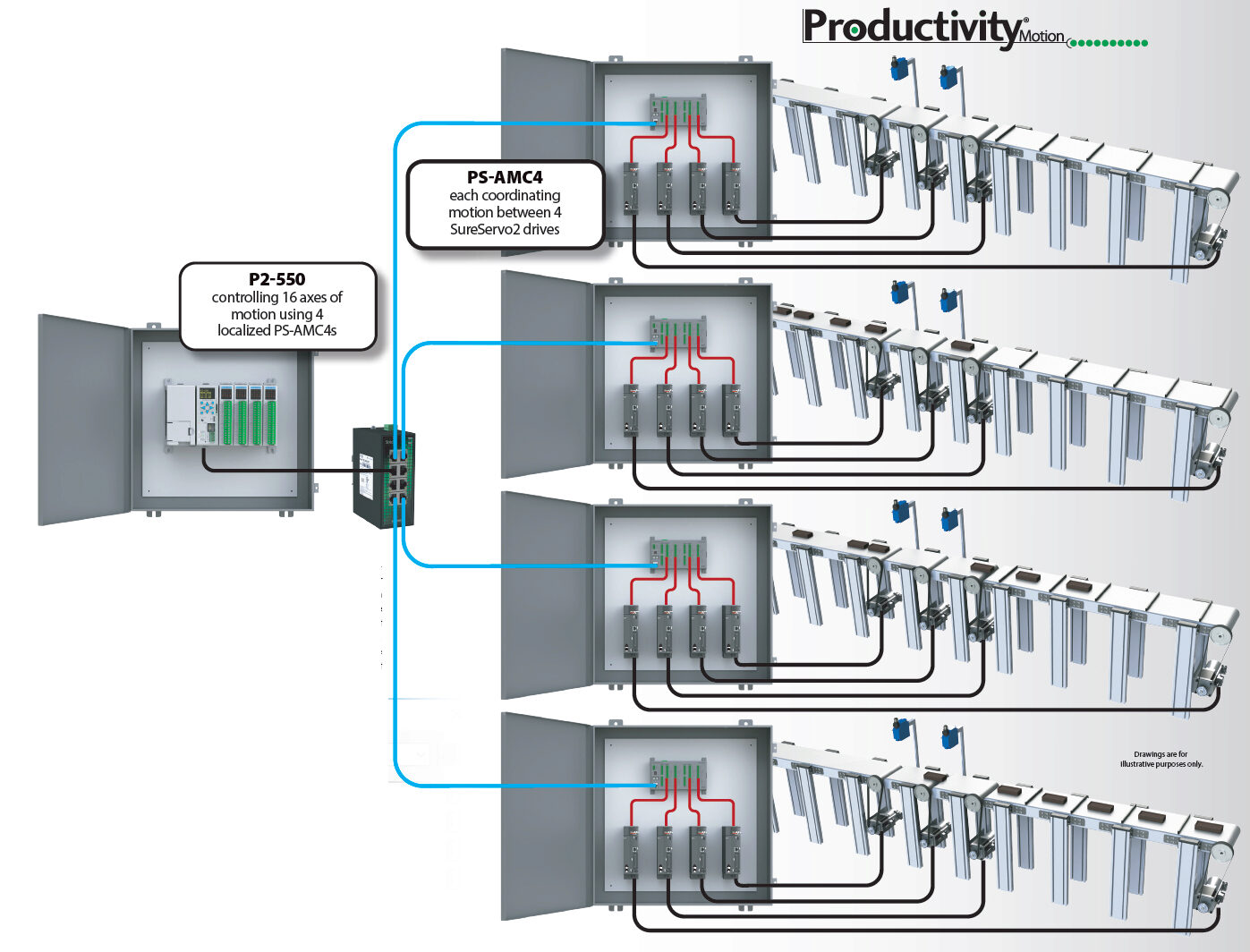

Easily control up to 16 axes of motion across your facility

Each remote I/O capable Productivity2000/3000 CPU can control up to 16 axes using four PS-AMC4 controllers each coordinating up to four axes on their own (P1000 systems can control up to 4 axes using 1 PS-AMC controller). So whether you have a single system with 4 or more axes of motion, multiple coordinated systems across your facility, or if you're anticipating future expansion, the PS-AMC is a perfect solution for your motion application.

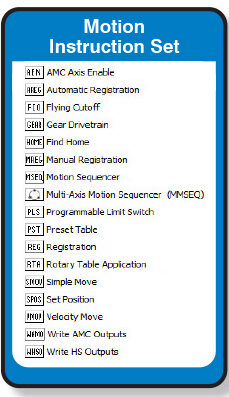

The Productivity Suite software provides the following for the PS-AMC:

- Motion profile set-up with easy-to-use built-in motion instructions

- Software test tool allows you to test the hardware without any ladder code - very useful for validating the physical wiring

- Real-time status and diagnostic information

- Plug-and-play hardware configuration using auto-discovery of the AMC units

Smart conveyor application

When it comes to package handling, pick-and-place or similar applications, product spacing is very important. One way to ensure proper spacing is to send the products through a smart conveyor system. With a smart conveyor, products arriving from an upstream process are brought to the right distance and phase position using several belts that are electronically coupled with each other through a PS-AMC controller. Each conveyor's servo motor will speed up or slow down to achieve the appropriate spacing between products. Four coordinated four-belt smart conveyor systems can be controlled with just one CPU.

Productivity from A to X-Y-Z

When it comes to X-Y-Z positioning, commonly achieved with gantry systems, the PS-AMC motion controller makes it easy. With the PS-AMC, Productivity CPU, and the Multi-Axis Motion Sequencer (MMSEQ) instruction, you can:

- Perform smooth movements between two or more points in up to 3 axes, plus an optional tool axis.

- Easily code For/Next or Do/While loops to repeat portions of the sequence, as desired.

- Iterate through up to 64 steps in a motion sequence, including adding timers and pauses between move actions.

Milling/routing application

When milling or routing materials to match specifications, accuracy is key. Just the slightest misstep during a cut can cause a complete redo and wasted material. Most milling machines utilize three axes of motion (X , Y, and Z axes) and require accuracy that is repeatable time and time again, making these types of applications perfect for ProductivityMotion components.

Precise linear interpolation

A common task in motion control applications is straight line motion. This can be accomplished using multiple axis of motion that work together to perform a linear move from one point to the next. This is also known as linear interpolation. The PS-AMC combined with a Productivity CPU allows you to precisely control each axis so that they all move in unison to reach the target position at the same time; resulting in a straight line from start to finish.

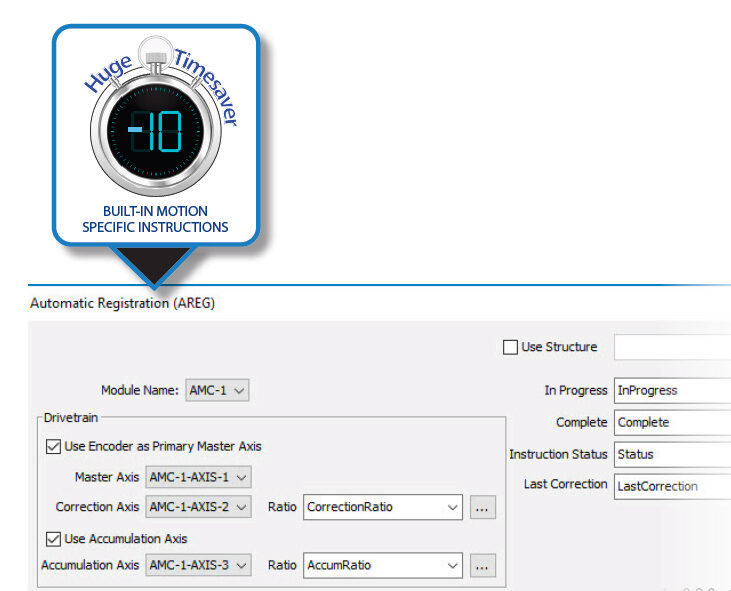

Precise positioning for when close enough just won't cut it

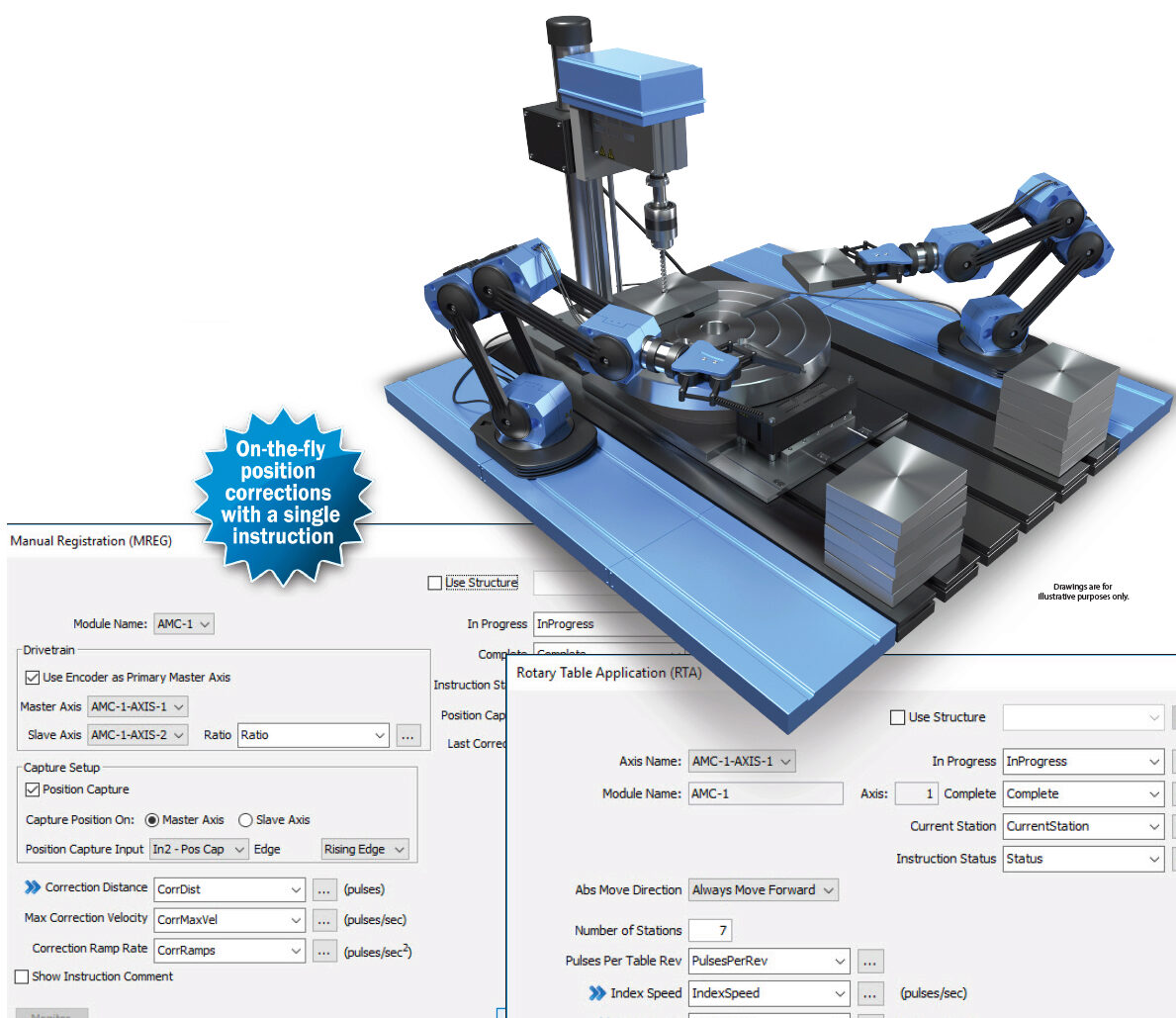

With machinery that uses coordinated motion where one move is dependent on another, especially in situations where a secondary move can only happen once the first has cleared its path, positioning inaccuracies can cause major production loss or even substantial equipment damage. Even small fluctuations can compound and become big issues if not corrected in time. The Productivity AMC has features built-in to compensate for measurement drift and allows on-the-fly position corrections to maintain superior accuracy.

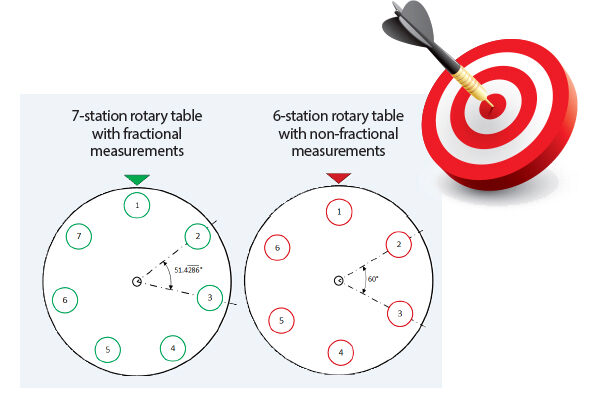

Rotary table application

Rotary table applications are very common in manufacturing and can be used to move products into position for drilling, welding, milling, or even for simple tool changes. Behind the scenes, rotary tables aren't very complicated and can be controlled with simple index moves to index the product to the next station or to a specific station.

Depending on the number of stations, one PS-AMC4 may be all you need to handle the rotation of the table, as well as, product placement and station movements.

Stay on target!

One inherent problem with this type of application (as well as other continuous, same direction motion applications), is when the difference between steps/stations is fractional. If the controller doesn't account for these fractions, the system will drift. The PS-AMC controller takes this into consideration and will accurately handle fractional steps to prevent drifting over time and always remain on target.

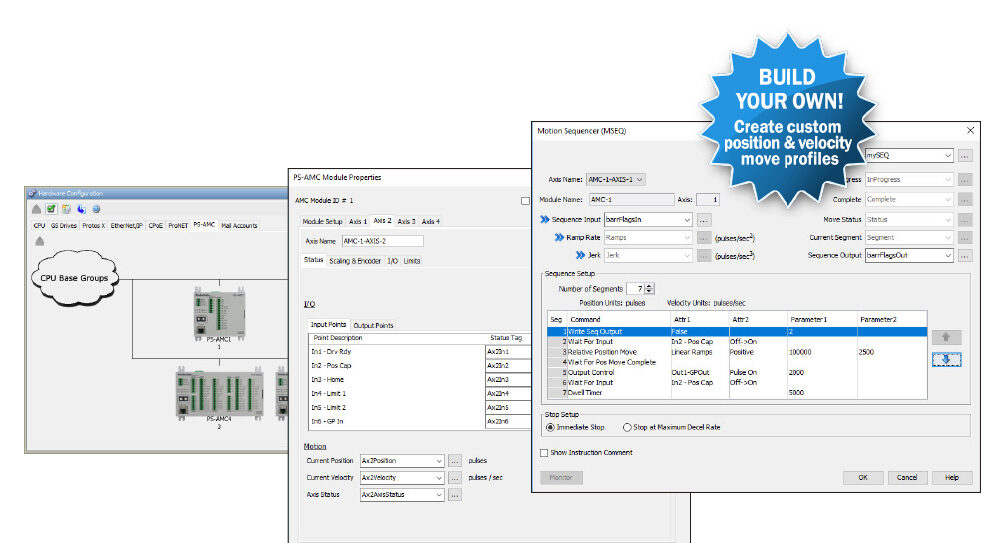

A-M-C, easy as 1-2-3!

Once your PS-AMC arrives, install the controller either locally to or remotely from the CPU and connect the needed Ethernet cable(s). Wire up the system, power the controllers, and download the free Productivity Suite software to your PC if you haven't already. At this point, you could use the software test tool in Productivity Suite to test the hardware and verify the physical wiring, otherwise on to step 2.

With the communication cables connected, and power applied, the Productivity CPU will auto-discover any PS-AMC controllers that are on the same Ethernet network. Once discovered, you can easily set the hardware parameters and modify data tags from within Productivity Suite.

Productivity Suite has numerous built-in motion instructions that allow you to quickly and easily configure standard motion profiles like flying cut off, rotary tables, and more using simple drop-down selections. If you need something different, you can also create your own custom move profiles using the Motion Sequencer (MSEQ) instruction. Create your profile, download the updated project file to the CPU, and you are done!

- Flying cut-off systems

- Press feeds

- In-line bottle filling

- Auger fillers

- Label applicators

- Smart conveyor systems (random timing infeeds)

- Rotary tables

- Vertical-form-fill-seal

- Case erectors/packers

- Cut to length systems

- High-speed mail sorting

- WebFilm handling

- Boring/drilling/tapping

- Coil winding

- Wrapping

- Thermo-formers

- Rotary knives

- And many more...

Use the PS-AMC with select Productivity series CPUs for low cost, coordinated motion control in any application

Practical motion control for simple systems

The P2-HSI/HSO modules are a great option for basic motion control applications. Combined with the numerous communication abilities built into the P2000 CPU, these modules give you a very practical motion solution for a lot less than the cost typically associated with motion. But don't let the price fool you. These little guys can stand head-to-head with modules you've been paying much more for.

Use the P2-HSI High-speed Input Module for high-speed counting and registration functions.

The P2-HSI is a high-speed (1MHz) input module that has both differential and single-ended inputs. This module accepts Pulse/Direction and Quadrature signals on each of two independent input channels. It also provides four general purpose high-speed inputs and four general purpose 5-24VDC @ 0.5 Amp outputs.

Pneumatic stamping application

The Registration (REG) instruction can trigger several internal and external position based events such as the capturing of positions, setting a tag, counting events and turning on, off or pulsing an output. The action can also be delayed by a set number of pulses as in this pneumatic stamping application. The P2-HSI module is used to accurately stamp parts as they move past on a conveyor. A blank part is detected by the sensor and the instruction is triggered. The output or stamping function is delayed by the appropriate number of encoder pulses. Once the part travels to the precise location under the stamp, the pneumatic stamp is activated and the image is stamped onto the part.

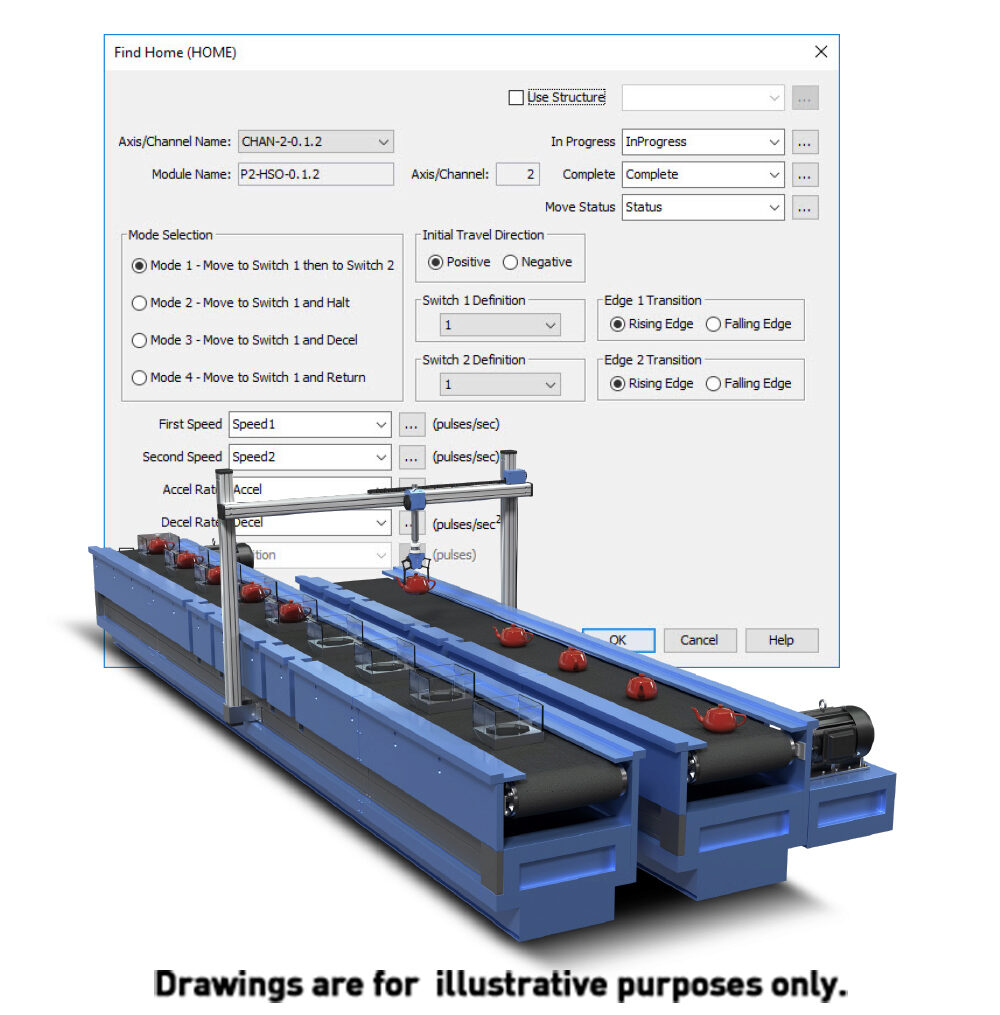

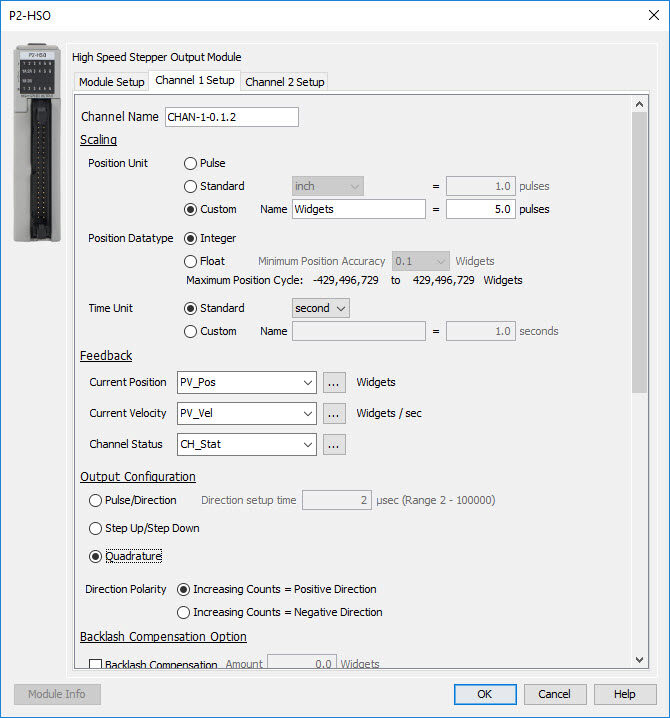

Use the P2-HSO High-speed Output Module for simple moves, velocity moves, and flexible homing routines.

The P2-HSO is a high-speed (1MHz) output module that supports Pulse/Direction, Step Up/Step Down and Quadrature pulse outputs on each of two independent output channels. It has both line driver and open drain outputs. Additionally, it has six general purpose inputs and four general purpose outputs. And with Productivity Suite's built-in instructions, like Find Home (HOME), Simple Move and Velocity Move (SMOV), it's easier than ever to program routines based on target position, target velocity, accel rate, decel rate, and more.

Easy configuration

Both the High Speed Input (P2-HSI) and High Speed Output (P2-HSO) modules can be configured using Productivity Suite's intuitive function blocks. Simply define your tags for each input/output channel on the appropriate Channel (1 or 2) Setup Tab. You can even specify custom units, and with the P2-HSI take advantage of an estimated velocity function.

Pick and place application

The Find Home (HOME) instruction initializes this pick and place application on power-up. Homing routines are used to align the P2-HSO channel position to a known real-world physical position. Choose from four preconfigured move routines and simply identify the desired speed, direction and acceleration.

High-speed I/O that won't skip a beat!

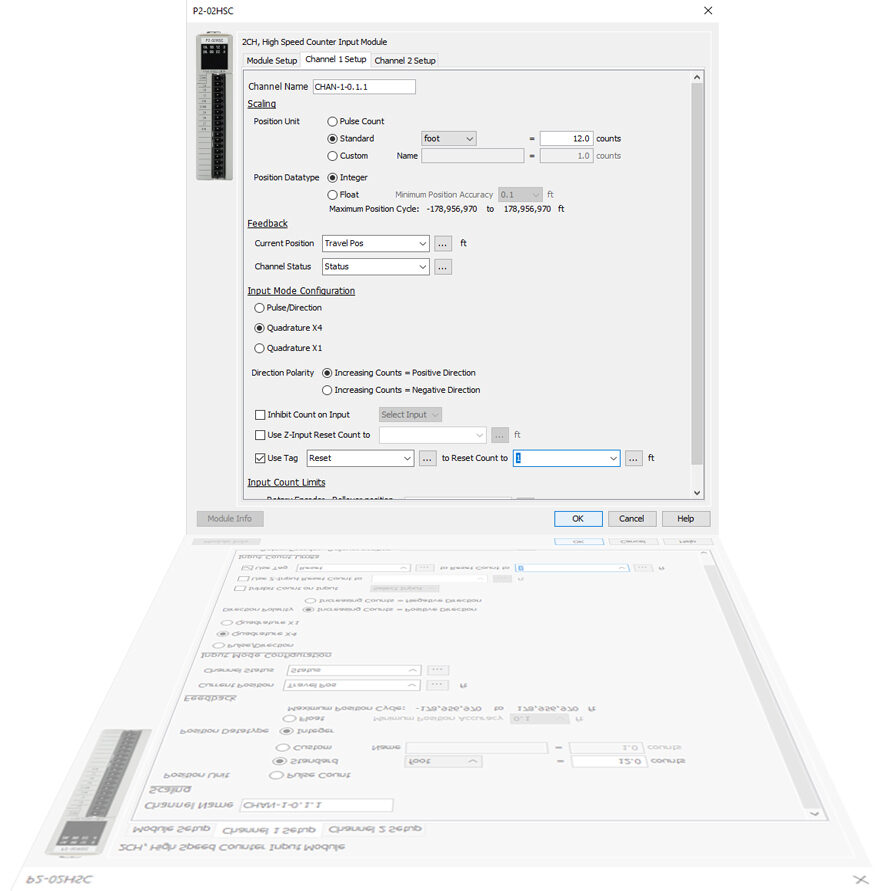

Besides the advanced P2-HSI and P2-HSO modules, Productivity2000 PLCs also offer lower-cost high-speed counter and pulse-width modulation modules. These modules are tailored for specific high-speed functions that are beyond the realm of generic I/O.

Setup is a cinch!

ProductivitySuite makes it easy to configure your I/O modules. Simply use the convenient fill-in-the-blank GUI to pick the functions you desire, set the scaling (standard or custom), assign the appropriate tags or create them on the fly, it couldn't be any easier.

High-speed Counter (HSC)

The P2-02HSC is capable of handling input pulse frequencies up to 100kHz. Easily count and/or calculate pulse rates from dedicated inputs or encoder signals that are used in many applications including package tracking and picking systems. Additionally, there are two general purpose inputs for use as 5-24 VDC inputs.

Pulse Width Modulation (PWM)

The P2-04PWM pulse width modulation module provides up to four channels of sinking or sourcing 0-20 kHz, 0-100% duty cycle outputs. The varying pulse widths produced by the PWM module are seen as varying power levels to the end device and are ideally suited for running motors/pumps, controlling LED lighting, opening/closing solenoid valves and more.

Real-time Data, Big-time Savings

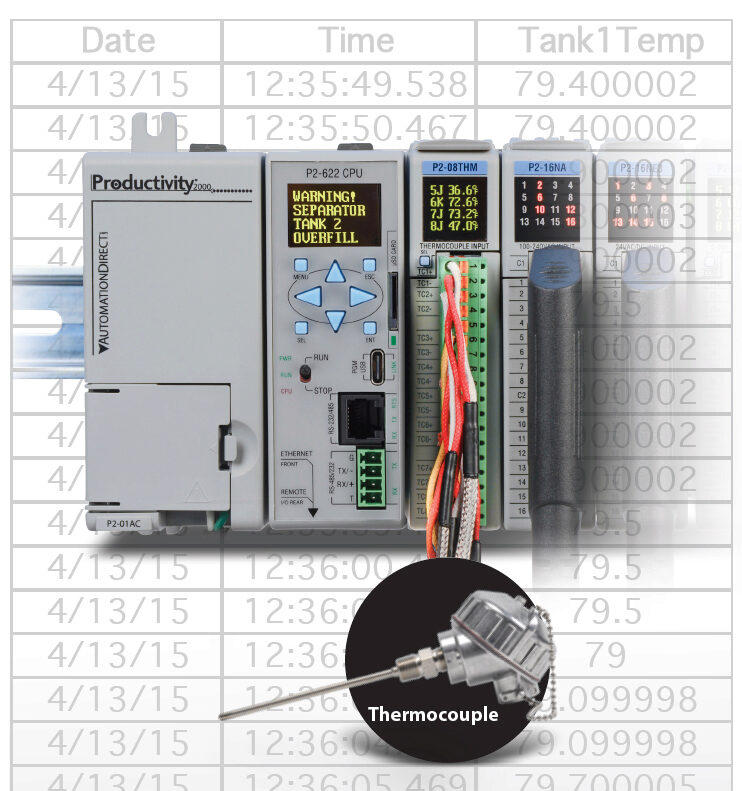

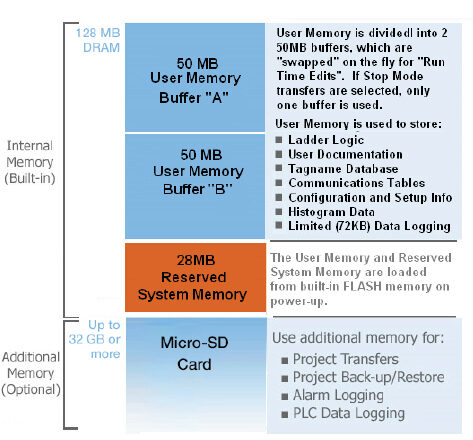

Built-in data logging

Track up to 64 tags at a time and save the data to the removable micro-SD card housed in the CPU. Capture up to 32GB of data either periodically (minute, hour, day, week, etc.) or when certain events occur. Scheduling and setup is done with the easy-to-use Data Logger configura-tion tool in the software. Log tag data, system errors and system events which can be used to track efficiency and performance, troubleshoot reoccurring or intermittent faults, and predict future breakdowns.

The micro-SD card can also be used to upload or download a project to/from a Productivity2000 without having a PC present. This feature is great for updating remotely located PLCs - just send your project on the micro-SD card to any factory in the world, and the controller can be updated with the most current project.

File Handling for Data Efficiency

Productivity Suite offers several file handling instructions so you can access vital data, on-the-fly, from within the ladder code.

- FRX (File Read) can read data from .csv files on the CPU external storage device into the ladder code

- FWX (File Write) can write data from ladder code to .csv files on the CPU external storage device

- FCX (File Control) can check file size, search for a file, copy a file, and delete a file on the CPU external storage device

- RTS (Retentive Tag Sync) can save retentive tag values to or restore retentive tag values from the CPU external storage device

*Supported by P2-622 CPU only

C-more data!

Easily integrate your PLC tag database into the C-more HMI for added visibility and logging of critical data. Trend graphs, bar graphs, analog meters, etc. are available to make your data easily understandable. An additional 32GB of data logging is possible with the C-more HMI's SD card slot. 12 and 15-inch panels include two SD card slots.

- 16 pen trends

- PID faceplate

- PID with trend faceplate

- Each pen can be turned on/off

- True historical data logging

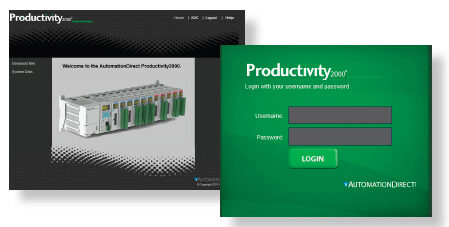

Direct access with the built-in Web Server

Having an integrated microSD card slot in the CPU allows you to configure tags to be logged (up to 32GB). You can easily remove/replace the memory card, or you can access the data via a standard Web browser using the CPU's built-in Web server.

Once enabled, simply enter your CPU's IP address into a browser's address bar, enter the appropriate security credentials and you have access to system data (error history, CPU status, scan time, etc.) or you can access the data log file directly on the microSD card.

This gives you a quick and convenient troubleshooting tool without having the programming software connected.

50MB of user memory

Store your entire project with ALL documentation in the CPU, and never hunt for that old laptop again. You know, the only one that has the updated code from last summer when you made all those changes.

Sure, we recommend that you make a back-up, but who hasn't been burned by this classic PLC problem?

Now you can download the free software to any available PC, grab the project (with documentation) from the Productivity2000 CPU and you can quickly be productive with any required changes, updates, or troubleshooting.

Check out our job openings

Free Online PLC Training

FREE Video Tutorials

FREE e-Newsletter

Automation Notebook

Product Literature

White Papers

News, Product and Training Bulletins

E-Books

Safe &

Secure

Safe &

Secure

We accept VISA, MasterCard, Discover, American Express, PayPal or company purchase orders.

Voted #1 mid-sized employer in Atlanta

Check out our

job openings

Loading...

Loading...