Cookies are not enabled on your browser.

Cookies are not enabled on your browser.Cookies are required for our site. Please enable cookies in your browser preferences to continue.

- Barcode / RFID / Vision

- Bulk Wire & Cable

- Cables (Terminated)

- Circuit Protection / Fuses / Disconnects

- Communications

- Drives & Soft Starters

- Enclosure Thermal Management & Lights

- Enclosures & Racks

- Field I/O

- HMI (Human Machine Interface)

- Hydraulic Components

- Motion Control

- Motor Controls

- Motors

- Pneumatic Components

- Power Products (Electrical)

- Power Transmission (Mechanical)

- Process Control & Measurement

- Programmable Controllers

- Pushbuttons / Switches / Indicators

- Relays / Timers

- Safety

- Sensors / Encoders

- Stacklights

- Structural Frames / Rails

- Tools & Test Equipment

- Valves

- Water (Potable) Components

- Wiring Solutions

- Retired Products

- Programmable Logic Controllers

- Productivity1000 PLCs

- Productivity2000 PLCs

- Productivity3000 PLCs

- ProductivityCODESYS

- LS Electric XGB Series PLCs

- ProductivityOpen

- CLICK PLCs

-

Do-more H2 PLCs or

Do-more T1H Series - Do-more BRX PLCs

- C-more Touch Panels

- AC & DC Drives

- Motion Control Components

- Servos

- StrideLinx

- Pneumatics

Configuration Utilities

- PLC Family Selector

- P1000 PLC Systems

- P2000 PLC Systems

- P3000 PLC Systems

- ProductivityCODESYS

- CLICK PLC Systems

- Do-more® BRX PLC Systems

- LS-Electric® XGB PLC Systems

- Productivity®Open Systems

- AC Motors

- Datalogic® Safety Light Curtains

- LS-Electric® Servo Systems

- Nitra® Pneumatic Grippers

- Object Detection (Sensors)

- PAL Controller Configurator

- Precision Gearbox Selector

- Protos X® Field I/O

- Quadritalia® Modular Enclosures

- Stellar® Soft Starters

- Stepper System Selector

- SureFrame T-slot Extrusion

- SureMotion® XYZ Gantry

- SureServo2® System Selector

- SureStep® Linear Actuators

- Timing Belts & Pulleys

- Werma® Stacklights

- ZIPLinks

Cylinder Sizing & Force

| Bore Dia. & Cylinder Area | |

|---|---|

| Bore Dia: | Cylinder Area (Sq. in.) |

| 7/16" | 0.150 |

| 9/16" | 0.249 |

| 3/4" | 0.442 |

| 7/8" | 0.601 |

| 1-1/16" | 0.887 |

| 1-1/4" | 1.23 |

| 1-1/2" | 1.77 |

| 2" | 3.14 |

| 2-1/2" | 4.91 |

| 3" | 7.07 |

| 3-1/4" | 8.30 |

| 4" | 12.57 |

| 5" | 19.64 |

| 6" | 28.27 |

| 8" | 50.27 |

| 10" | 78.54 |

| 12" | 113.10 |

Cylinder Sizing

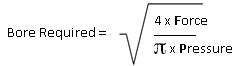

The equations below & chart at right show the relationship between the force required to move a load, the pressure available and the required cylinder bore size. Always factor in 25% more force than actually required to overcome friction, pressure drop, and other factors.

Where:

Interactive Cylinder Bore Calculator:

Example:

Given an estimated force required of 900lbs (including the 25% overage for friction, pressure drop, etc.) and that the system will operate at 80PSI:

- The Required Piston Area = 900 lbs ÷ 80 lbs/in2 = 11.25 in2.

- Divide 11.25 by π, take the square root to get r, and note that the bore (dia) must be at least 3.78 inches.

- From the chart, the next largest cylinder diameter is 4". Use a 4" cylinder.

Cylinder Force

The force a cylinder can apply during extension is a simple calculation (the inverse of the above formula): the effective surface area of the cylinder's piston × the differential pressure. For example: a 4" cylinder has a surface area of 12.57 square in. (πr²). If that cylinder is extended with 100 PSI of air pressure, it can supply a force of 1257 pounds.

Factoring in the Rod

When retracting a double acting cylinder, the cylinder rod blocks a portion of the effective surface area. If that same 4" cylinder has a 1" rod, the effective surface area is reduced to 11.78 sq. in. and it can only supply 1178 pounds of force while retracting (given the same 100 PSI differential pressure).The following chart shows the available force (in pounds) for both extension and retraction. White rows show extension force, which takes advantage of the full piston area. Grey rows show retraction forces with the rod diameter taken into account.

Spring Return

If you choose a cylinder with spring return, be sure to factor in the additional force needed to overcome the spring during extension.

Differential Pressure

Pressures shown across the top of the chart are differential pressures across the two cylinder ports. In practice, the air supply line must supply another 5% of pressure to make up for cylinder loss, and must supply 25-50% additional pressure to make up for flow losses in lines and valving so the cylinder will have sufficient travel speed.

Systems should always be designed with calculated forces at least 25% above the actual requirements.

| Cylinder Force (Pounds) | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Bore Size |

Rod Dia. |

Effec. Area (in²) |

Differential Pressure (PSI) | ||||||||||

| 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | 110 | 120 | |||

NOTES:

- This chart does not take into account cylinder loss, flow loss in lines or valving, etc. Cylinders sized too closely may not have sufficient travel speed.

- Systems should always be designed with available forces at least 25% above the actual requirements.

- White rows show extension force, which takes advantage of the full piston area. Grey rows show retraction forces with the rod diameter taken into account.

Check out our job openings

Free Online PLC Training

FREE Video Tutorials

FREE e-Newsletter

Automation Notebook

Product Literature

White Papers

News, Product and Training Bulletins

E-Books

Safe &

Secure

Safe &

Secure

We accept VISA, MasterCard, Discover, American Express, PayPal or company purchase orders.

Voted #1 mid-sized employer in Atlanta

Check out our

job openings