Cookies are not enabled on your browser.

Cookies are not enabled on your browser.Cookies are required for our site. Please enable cookies in your browser preferences to continue.

- Barcode / RFID / Vision

- Bulk Wire & Cable

- Cables (Terminated)

- Circuit Protection / Fuses / Disconnects

- Communications

- Drives & Soft Starters

- Enclosure Thermal Management & Lights

- Enclosures & Racks

- Field I/O

- HMI (Human Machine Interface)

- Hydraulic Components

- Motion Control

- Motor Controls

- Motors

- Pneumatic Components

- Power Products (Electrical)

- Power Transmission (Mechanical)

- Process Control & Measurement

- Programmable Controllers

- Pushbuttons / Switches / Indicators

- Relays / Timers

- Safety

- Sensors / Encoders

- Stacklights

- Structural Frames / Rails

- Tools & Test Equipment

- Valves

- Water (Potable) Components

- Wiring Solutions

- Retired Products

- Programmable Logic Controllers

- Productivity1000 PLCs

- Productivity2000 PLCs

- Productivity3000 PLCs

- ProductivityCODESYS

- LS Electric XGB Series PLCs

- ProductivityOpen

- CLICK PLCs

-

Do-more H2 PLCs or

Do-more T1H Series - Do-more BRX PLCs

- C-more Touch Panels

- AC & DC Drives

- Motion Control Components

- Servos

- StrideLinx

- Pneumatics

Configuration Utilities

- PLC Family Selector

- P1000 PLC Systems

- P2000 PLC Systems

- P3000 PLC Systems

- ProductivityCODESYS

- CLICK PLC Systems

- Do-more® BRX PLC Systems

- LS-Electric® XGB PLC Systems

- Productivity®Open Systems

- AC Motors

- Datalogic® Safety Light Curtains

- LS-Electric® Servo Systems

- Nitra® Pneumatic Grippers

- Object Detection (Sensors)

- PAL Controller Configurator

- Precision Gearbox Selector

- Protos X® Field I/O

- Quadritalia® Modular Enclosures

- Stellar® Soft Starters

- Stepper System Selector

- SureFrame T-slot Extrusion

- SureMotion® XYZ Gantry

- SureServo2® System Selector

- SureStep® Linear Actuators

- Timing Belts & Pulleys

- Werma® Stacklights

- ZIPLinks

Cylinders

Pneumatic cylinders are mechanical devices that use compressed air acting on a piston inside a cylinder to move a load along a linear path. There are many styles of pneumatic actuators: diaphragm cylinders, rodless cylinders, telescoping cylinders and through-rod cylinders.

Basic Styles

The most popular style of pneumatic actuator consists of a piston and rod moving inside a closed cylinder. Even so, there are a large variety of construction techniques and materials to fit a wide range of applications and user preferences. Body materials can be aluminum, steel, stainless steel and even certain polymers. Construction can be either non-repairable or repairable. Learn more about the types of NITRA Cylinders offered by AutomationDirect.

There are two basic actuator styles based on their operating principle:

- Single acting cylinders have a single port to allow compressed air to enter the cylinder to move the piston to the desired position. They use an internal spring or sometimes simply gravity to return the piston to the "home" position when the air pressure is removed. Single acting cylinders are a good choice when work is done only in one direction such as lifting an object or pressing an object into another object.

- Double acting cylinders have a port at each end and move the piston forward and back by alternating the port that receives the high pressure air. This uses about twice as much energy as a single acting cylinder, but is necessary when a load must be moved in both directions such as opening and closing a gate.

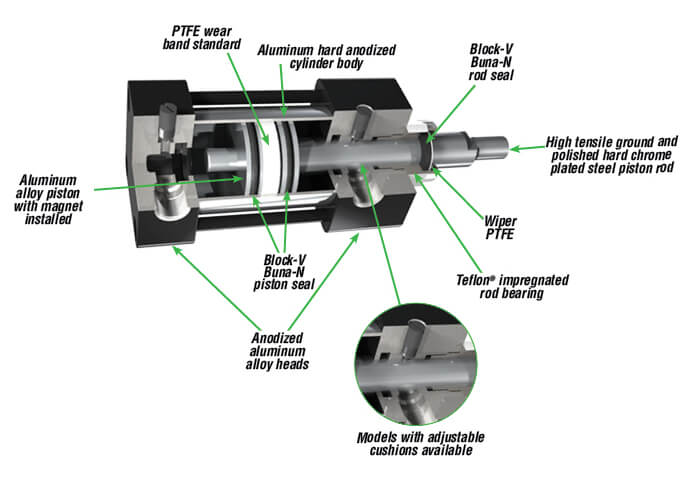

Double Acting Tie-Rod Cylinder Cutaway

In a typical application, the actuator body is connected to a support frame and the end of the rod is connected to a machine element that is to be moved. A control valve is used to direct compressed air into the Extend port while opening the Retract port to atmosphere. The difference in pressure on the two sides of the piston results in a force equal to the pressure differential multiplied by the area of the piston. If the load connected to the rod is less than the resultant force, the piston and rod will extend and move the machine element. Changing the valve to direct compressed air to the Retract port while opening the Extend port to atmosphere will cause the cylinder assembly to retract back to the "home" position (assuming again that the resultant force is enough to move the load).

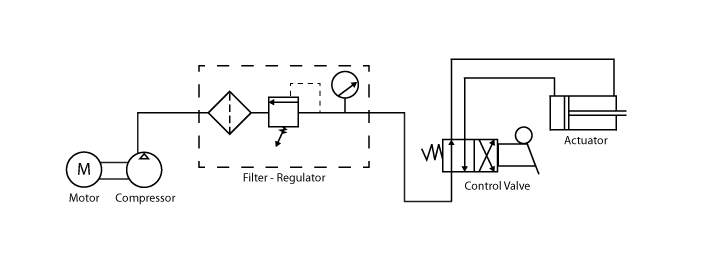

Pneumatic actuators are at the working end of a fluid power system. Upstream of these units, which produce the visible work of moving a load, there are compressors, filters, pressure regulators, lubricators, control valves and flow controls. Connecting all of these together is a network of piping or tubing (either rigid or flexible) and fittings.

Pressure and flow requirements of the actuators in a system must be taken into account when selecting these upstream system components to ensure the desired performance. Undersized upstream components can cause a pneumatic actuator to perform poorly or even prevent it from moving its load.

Force

When selecting an actuator it is important to properly match the cylinder to the job. Learn more about Cylinder Size and Force.

Speed

The speed at which the cylinder can move a load is directly related to the rate that the compressed air can flow through the pneumatic system to the piston to make it move. This can often be a little tricky to calculate, since as the flow rate increases, system resistance (basically friction of the air moving through pipes and components) will increase in a non-linear fashion. Learn more about Cylinder Speed.

Length

Stroke length is determined by the required travel of the machine element to be driven by the actuator.

Mounting

The final bit of basic selection criteria is the cylinder mounting arrangement. There are many different configurations available from various manufacturers. The more common ones include rigid nose or tail mount, trunnion mount, rear pivot mount and foot mount. A study of the machine motion required usually will show which mounting configuration is the best choice. Take a look at the myriad mounting options for cylinders here.

Special Features:

Once the basic actuator size and configuration is known, other options such as end-of-stroke cushions, magnetic piston (for position detection switches) or special seals should be considered when making the final selection.

Cushions

Cushions do an excellent job of preventing a piston from banging into the end caps at the end of stroke. Flow control valves can prevent banging also, but at the expense of a slow travel speed. Cushions only slow the travel for about the last half inch of stroke. A cushion is very useful when the design requires a higher cycle rate or speed and also smooth starting and stopping.

Magnetic Pistons (to facilitate position sensors)

Magnetic pistons allow simple magnetic proximity sensors to be mounted on a cylinder which can allow a control system to get feedback on the position of a cylinder. Since most cylinders are either extended or retracted, two proximity switches can monitor the operation of a cylinder. This can be very beneficial for machines that require a sequence of operations. Due to the nature of compressed air systems, the exact speed of a cylinder may vary slightly due to a number of factors outside of the control of the machines control system such as supply pressure variations, moisture content in the air, ambient temperature, etc. A control sequence that begins step two once step one is confirmed complete and so on is a much more robust design. Learn more about cylinder switches here.

Temperature Extremes

If you operate cylinders at extreme temperatures - say below -20°F or over 200°F - you should anticipate shorter cylinder life. Environmental conditions such as temperature extremes or corrosive materials (including caustic washdown) may require special seal materials such as Viton. Most manufacturers offer these special seals as an option.

Keep in mind that there are many factors such as system contamination, corrosion, minor leaks and wear that will affect the available air pressure and flow used to drive the actuator. A well-sized actuator and fluid power system shouldn't waste energy; it should also be tolerant of minor reductions in pressure and flow available due to the factors listed above.

When the correct pneumatic actuator is used, it's one of the cleanest and most cost-effective ways to produce linear motion. Its mechanical design that uses stored energy makes it very economical and reliable.

Check out our job openings

Free Online PLC Training

FREE Video Tutorials

FREE e-Newsletter

Automation Notebook

Product Literature

White Papers

News, Product and Training Bulletins

E-Books

Safe &

Secure

Safe &

Secure

We accept VISA, MasterCard, Discover, American Express, PayPal or company purchase orders.

Voted #1 mid-sized employer in Atlanta

Check out our

job openings