Cookies are not enabled on your browser.

Cookies are not enabled on your browser.Cookies are required for our site. Please enable cookies in your browser preferences to continue.

- Barcode / RFID / Vision

- Bulk Wire & Cable

- Cables (Terminated)

- Circuit Protection / Fuses / Disconnects

- Communications

- Drives & Soft Starters

- Enclosure Thermal Management & Lights

- Enclosures & Racks

- Field I/O

- HMI (Human Machine Interface)

- Hydraulic Components

- Motion Control

- Motor Controls

- Motors

- Pneumatic Components

- Power Products (Electrical)

- Power Transmission (Mechanical)

- Process Control & Measurement

- Programmable Controllers

- Pushbuttons / Switches / Indicators

- Relays / Timers

- Safety

- Sensors / Encoders

- Stacklights

- Structural Frames / Rails

- Tools & Test Equipment

- Valves

- Water (Potable) Components

- Wire & Cable Management

- Wire & Cable Termination

- Retired Products

Configuration Utilities

- PLC Family Selector

- P1000 PLC Systems

- P2000 PLC Systems

- P3000 PLC Systems

- ProductivityCODESYS

- CLICK PLC Systems

- Do-more® BRX PLC Systems

- LS-Electric® XGB PLC Systems

- Productivity®Open Systems

- Datalogic® Safety Light Curtains

- LS-Electric® Servo Systems

- Nitra® Pneumatic Grippers

- Object Detection (Sensors)

- PAL Controller Configurator

- Precision Gearbox Selector

- Protos X® Field I/O

- Pyrometers Selector

- Quadritalia® Modular Enclosures

- Stellar® Soft Starters

- Stepper System Selector

- SureFrame T-slot Extrusion

- SureMotion® XYZ Gantry

- SureServo2® System Selector

- SureStep® Linear Actuators

- Timing Belts & Pulleys

- Werma® Stacklights

- ZIPLinks

Affordable automation for EVERYONE!

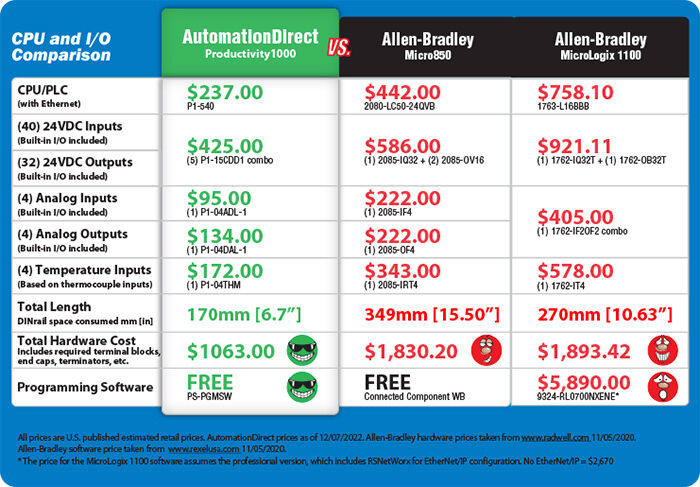

Our P1-540 Productivity CPU is priced at $237.00, theirs is priced at $442!

We want the opportunity to serve anyone in need of an affordable automation solution. Whether you're dealing with tight budget constraints or you're just tired of getting squeezed for every last dollar you have, the Productivity series of PLCs has a solution for you.

With a focus on customer satisfaction, the Productivity1000 PLC was designed to provide the advanced features you need at a price anyone, not just the big guys, but anyone can afford. On top of the low-cost hardware, you also get FREE software, FREE tech support for the life of the product, FREE training and many other goodies to help you smoothly and successfully complete your project.

Don't wait. Get started now for FREE!

The Productivity Suite programming software is available for download free of charge. Take it for a test drive before you buy or get started on your project immediately. There are no licensing fees or maintenance charges to be concerned with and any subsequent upgrades are available for free download as well. If you need assistance, the embedded help file contains detailed information on over 260 topics; also check out our instructional videos or give us a call at 770-844-4200 - we are here to help.

FREE Software!

Download as often as you need. No license or key needed. Click here to download the free software.

Your success is our success!

As the world around us becomes more and more automated, an understanding of electrical control systems becomes more and more vital. To better serve our customers and the industry we rely on, we offer absolutely free online training to anyone looking to learn PLCs. No purchase necessary! This training covers both basic PLC fundamentals as well as specific training on the Productivity Suite Programming Software. Check out this free training here: www.automationdirect.com/plc-training

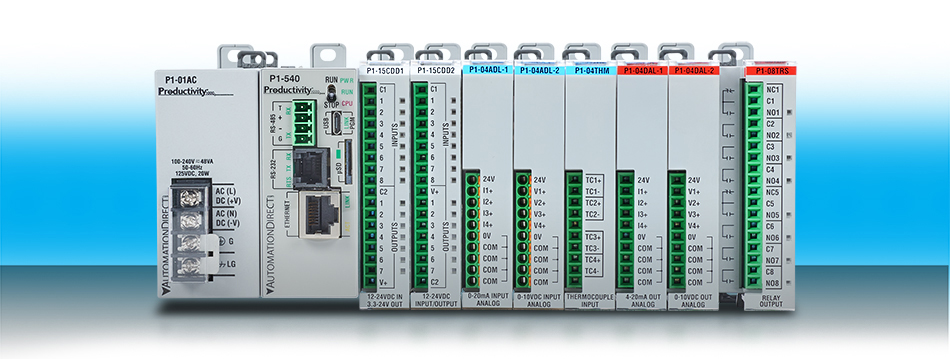

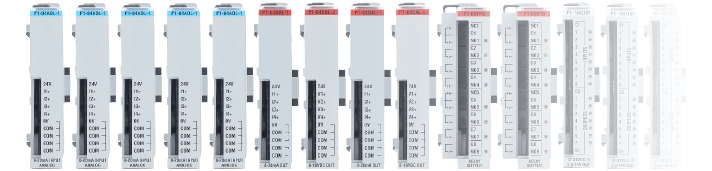

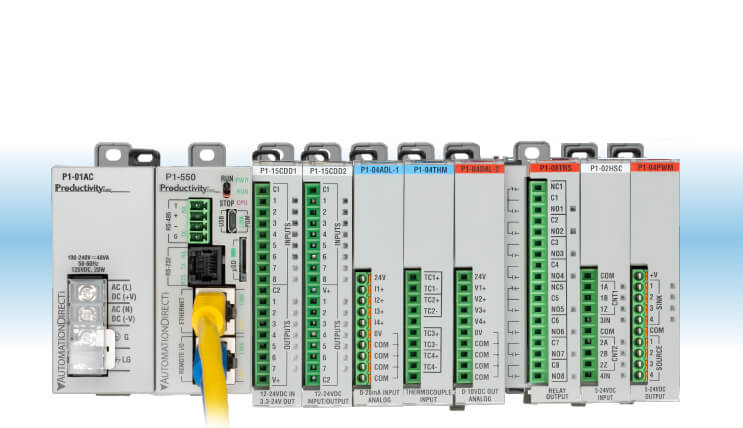

Expand with ease

The Productivity1000 requires no base or backplane and can easily be expanded with up to 15 snap-on I/O modules. The P1000 system can support up to 240 discrete I/O points or 120 analog I/O channels total. The I/O modules can be easily added or removed using the single latch mechanism on the topside of each module. This stackable design allows you to purchase only the I/O required for your particular application.

This versatility also means you can use the Productivity1000 CPU as a stand alone, low-cost data logger or protocol converter (no I/O modules).

I/O Expansion Modules starting at $43.00

Several expansion I/O modules are available to choose from:

- Discrete

- Analog

- Temperature

- Relay

- High Speed

- PWM

Need more I/O?

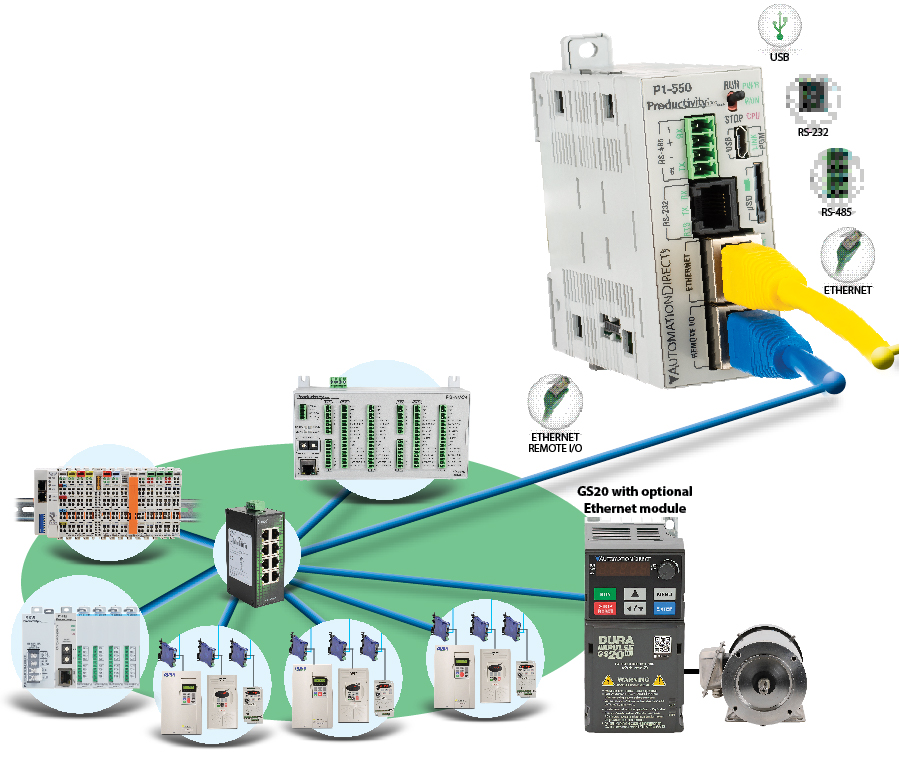

The P1-RX module adds remote I/O capability to the P1-550 CPU, providing up to 512 remote I/O points (4 remote bases with 8 modules each).

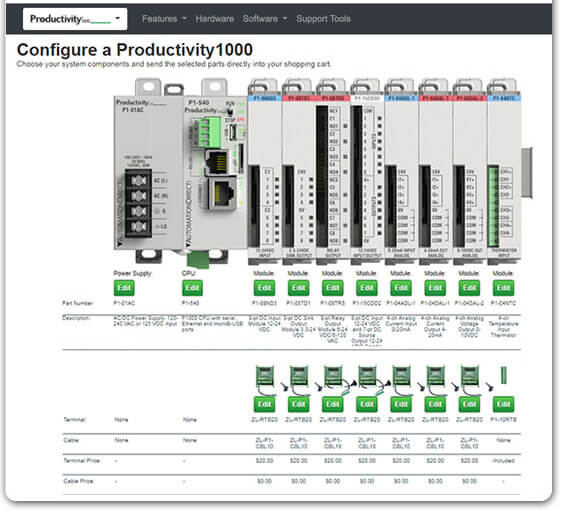

Interactive PLC Configurator Tool

Use the interactive PLC configurator tool on our webstore to quickly configure your Productivity1000 system to your specifications. Simply choose the CPU and I/O modules you require with the connection options you prefer and send the selected parts right to the shopping cart.

See how easy it is to use the configuration tool

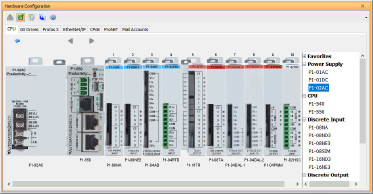

Get started in seconds with auto-discovered I/O modules

Once an I/O module is installed, in either the local or one of 4 remote racks, the P1000 will automatically discover the module and create a realistic picture of your configuration in the free Productivity Suite software. Physical I/O tags will be generated based on each module's position in their rack and that's it! You are ready to program with the auto-configured settings just seconds after power-up, or you can reconfigure the setup and assign new tags manually.

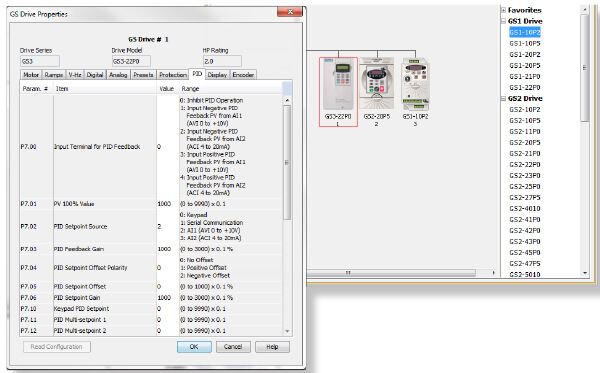

VFDs configured with ease!

The Productivity Suite software is designed to recognize any AutomationDirect GS series drive. Simply connect the drive to the Remote I/O port of the P1-550 CPU and it is discovered in the Productivity Suite software. No more searching through drive manuals to find the parameter you need, each parameter, with description, range, and value, is available in the software.

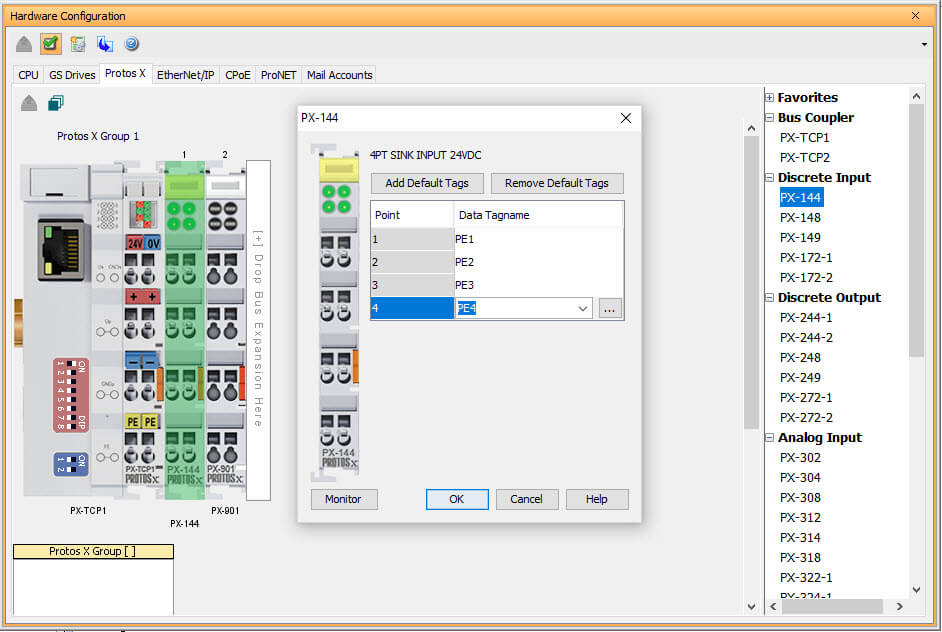

Integrated field I/O

The Productivity Suite software will auto detect the Protos X field I/O system (using a Modbus coupler) connected to the Remote I/O port of the P1-550 and automatically assign tags to the installed I/O terminals. The configuration can be manually changed and it is saved within the PLC project.

Support information at your fingertips!

All Productivity1000 I/O modules have QR codes printed on the underside of their wire covers. Scan the code with your smart phone or tablet QR app to get the latest specifications/wiring diagrams for that module.

BIG PLC features in a small package for a tiny price!

The Productivity1000 series PLCs are designed with features you'd expect to pay a whole lot more for. Built-in data logging, tag name programming, limitless PID, web server and mobile access, plus many other advanced features are packed into this budget and space-saving PLC series.

Up to 32GB of data!

Built-in Data Logging

Track up to 64 tags at a time and save the data to the removable micro SD card stored in the CPU. Capture up to 32GB of data either periodically (minute, hour, day, week, etc.) or when certain events occur. Scheduling and setup is done with the easy-to-use Data Logger configuration tool in the software. Log tag data, system errors and system events which can be used to track efficiency and performance, troubleshoot recurring or intermittent faults, and predict future breakdowns.

Web Server

With the P1000 CPU's integrated Web Server, you can access Data Logger files stored on an installed flash device (optional) as well as monitor system status via the (read-only) System Tags.

Apple iOS PACDATA app

The FREE PAC/PLC Data Remote Monitor App allows you to connect to remote P1000 systems from a Wi-Fi or cellular network connection. The Remote user can monitor the local PLC system and user tags configured for remote access inside the tag database of the controller.

No-Limit PID

With 50MB of user memory, you have practically limitless PID functionality. The integrated PID function blocks make it easier to configure and control the process loops in your application.

The PID Monitor utility allows you to monitor your loops and tune them in real time. We also offer a built-in Auto-tuning algorithm (Ziegler-Nichols) to help give you a jump on fine tuning your loops.

The PID instruction supports either individual or cascade mode operation. It also includes a tab for configuring all of your process alarms, including Low-Low, Low, High, High-High Limits and Deviation Alarms.

Timesaving Tag Names!

Export your tag name database from the Productivity1000 and import it into C-more software to jump start your HMI development. No more digging through your notes, or hunting through your ladder logic to find the right tag name.

Connect up to 16 C-more HMIs to the Productivity1000 via Ethernet for control and visibility of your process/machine from anywhere in your factory.

We make PLC communication affordable!

Two serial ports included on CPU

Two serial ports are included on the Productivity1000 CPUs for communication to peripheral devices:

(1) RJ12 (6P6C) port for RS-232 devices

(1) 4-wire screw terminal for RS-485 multi-drop devices

These ports provide Modbus RTU Master/Slave capability, ASCII In and Out capability and Custom Protocol over Serial capability.

The RS-485 port can support up to 50 multi-drop devices (more if repeater is added to network).

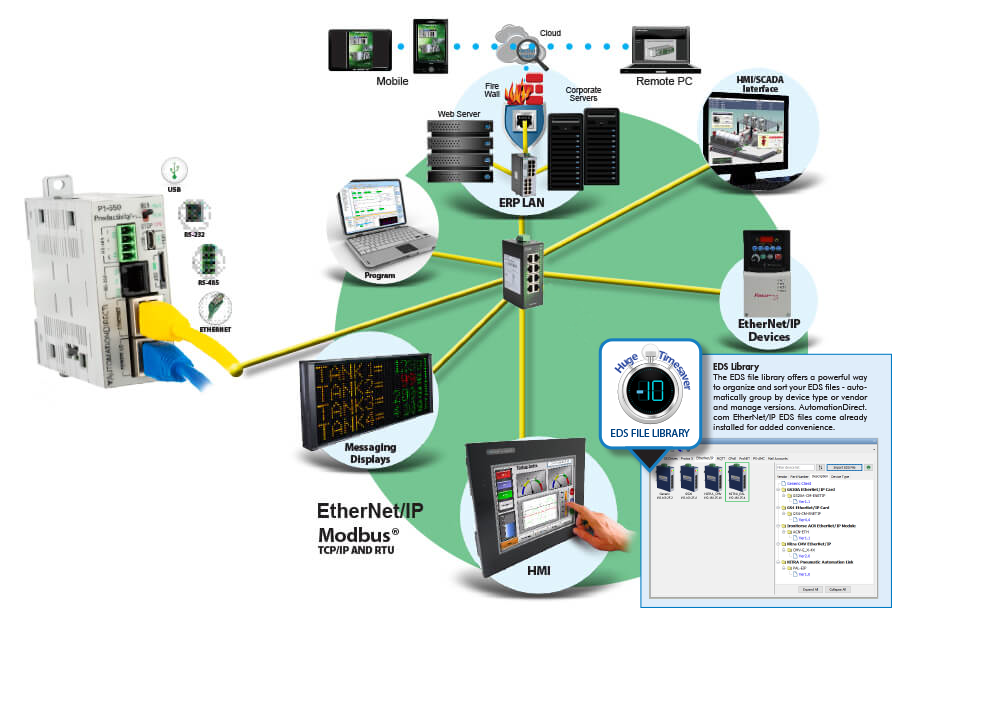

Built-in Ethernet on the CPU has got you covered!

Both Productivity1000 CPUs come standard with a general purpose Ethernet port and two of the top industrial Ethernet protocols in our market. Modbus TCP and EtherNet/IP are a must for any up-to-date networked control system. MQTT is also supported which is fast becoming an industry requirement as the IIoT and machine-to-cloud connections become more and more prevelant.

Ethernet ports:

10/100Mbps multipurpose Ethernet port for programming, monitoring, firmware upgrades and a mixture of the following client/server connections:

- 16 Modbus TCP Client connections (CPU Master)

- 16 Modbus TCP Server connections (CPU Slave)

- 32 EtherNet/IP Scanners (CPU Master)

- 4 EtherNet/IP Adapters (CPU Slave)

- 4 cloud connections using MQTT

A total of 128 EtherNet/IP connections and over 5000 EtherNet/IP messages per second! And unlike many controllers, the Productivity series CPUs support both Explicit and Implicit (I/O) messaging for greater functionality.

The Productivity1000 also provides a Custom Protocol over Ethernet (CPE) option which gives the user the ability to create their own communications protocol between the Productivity series CPU and a 3rd party Ethernet device via TCP or UDP.

The ProNET feature is also available and allows any P-series CPU to seamlessly share data by publishing to or subscribing to data from other P-series CPUs. Up to 32 publishers and/or subscribers are allowed per CPU.

EtherNet/IP

Productivity Suite makes communicating with EtherNet/IP devices a snap.

- Scanner and adapter supported

- Implicit application types supported include input-only and listen-only

- EDS file configuration presented in an easy-to-use drop-down menu

- Ability to select multiple connection options from an EDS file which simplifies configuration

- The EDS file library offers an easy way to upload, store, and manage your EDS files

- AutomationDirect.com EtherNet/IP EDS files are preloaded in the library for convenience

P1-550 only: Remote I/O, 10/100Mbps Ethernet port (bottom)

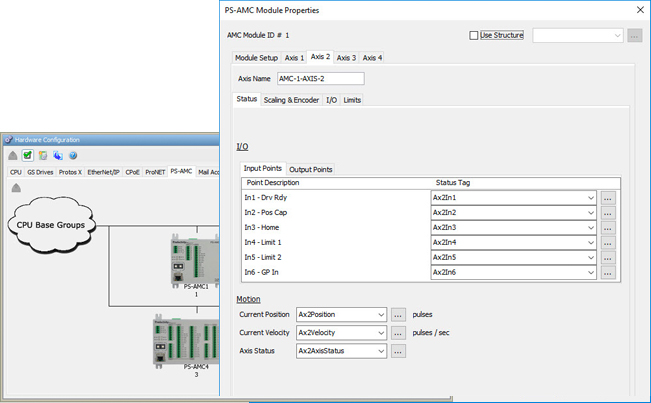

Supports up to 16 GS series variable frequency drive connections, 1 PS-AMC controller, 4 Protos X field I/O racks and/or 4 P1-RX remote I/O expansion racks.

GS Drive, PS-AMC and Protos X field I/O configurations are easily modified within ProductivitySuite and saved with the PLC project.

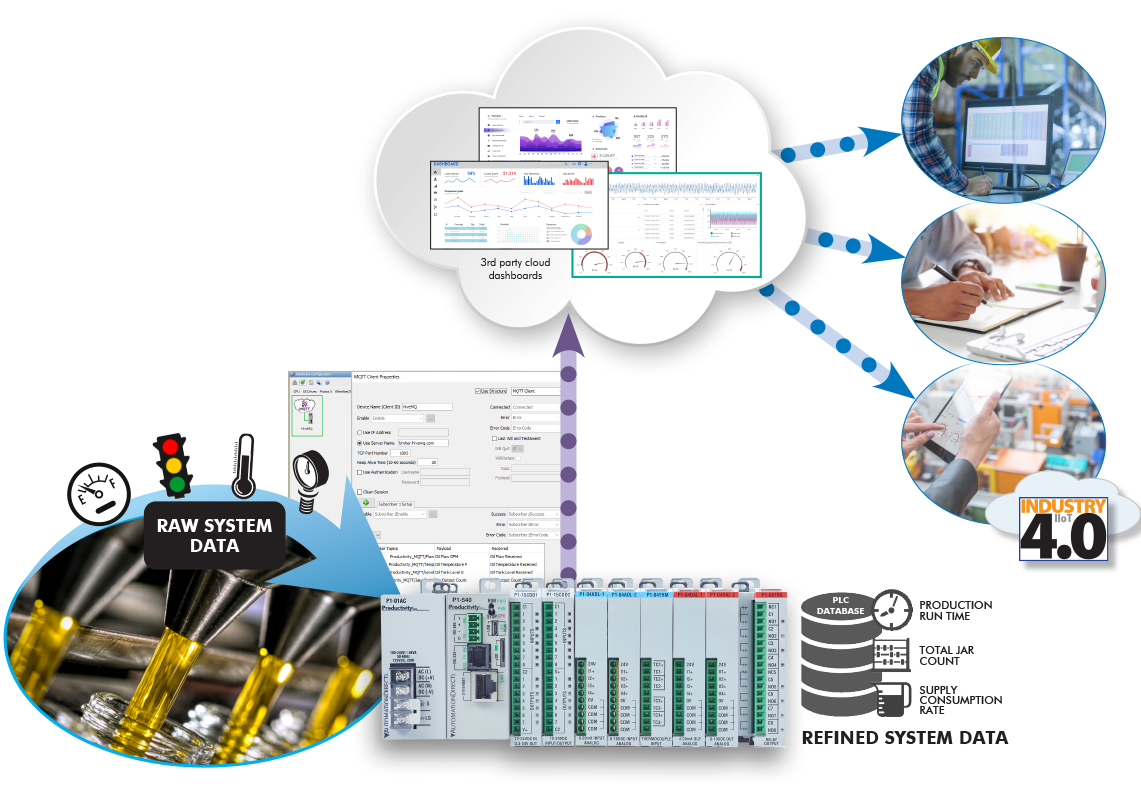

We make cloud communication easy

Industrial machines/systems are more connected than ever before, whether internally with upstream IT management systems or externally with remote support personnel, modern-day plant-floor machines/systems need to communicate to a variety of networks. Cloud networking, with its computing and data storage platforms, has also become a viable solution for analyzing and accessing production data from anywhere at anytime. Using powerful cloud platforms such as Microsoft Azure® or IBM Watson® to analyze production-floor data can provide better process efficiency, improved plant-wide resource management and less operational downtime.

But how does data from a simple level switch on a tank get to the cloud? With Productivity PLCs, it easy! Productivity PLCs have the communication capabilities and processing power needed to not only control plant-floor machines but gather valuable data from them, package it, and send it on to higher level analysis systems.

Mulitple data gathering options

Productivity PLCs offer many I/O options to choose from for your system data collection. I/O modules, available in analog, discrete, high-speed, relay, and temperature versions, allow you to create the custom I/O configurations your application needs. And with Modbus RTU, Modbus TCP and EtherNet/IP protocol support, Productivity1000 PLCs can easily gather raw data from a variety of VFDs, sensors, switches, encoders, pilot devices, or almost any other control component your system may have.

MQTT

The MQTT protocol has become the frontrunner for many machine-to-machine (M2M) and IIoT/cloud networking applications, due to its lightweight overhead and reduced bandwidth consumption. Productivity PLCs support MQTT communication and with fill-in-the-blank MQTT messaging configurations, delivering vital data to advanced cloud computing platforms is easy.

Compatible with MQTT brokers and cloud platforms/services including:

- IBM Watson®

- Mosquitto®

- HiveMQ®

- Thingsboard®

Refining data into something meaningful

The Productivity Suite programming software makes refining raw data into a meaningful metric a cinch. With a multitude of simple-to-use instructions combined with the computing power of a Productivity CPU, Productivity Suite can easily transform a raw process signal, like 4-20mA, into a consumption rate, a production throughput, an energy efficiency score, a rejection percentage, or any other metric that's vital to you.

Easy Coordinated Motion

Multi-axis motion control that's accurate and affordable

The PS-AMC motion controller is an ideal solution for motion control applications requiring several independent axes of motion and/or coordinated motion between some or all axes. Available in one to four axes models, the PS-AMC provides highly accurate positioning using encoder fed control (one encoder per axis). Used in conjunction with select Productivity CPUs and programmed with the FREE Productivity Suite software, the AMC can supply up to 1MHz of pulse-train command signals to servo or stepper drives for extremely responsive movements in any application.

Flying cut-off application

The primary function of a flying cut-off system is to synchronize the speed of a servo-driven carriage, on which a cutting mechanism is mounted, with the speed of a continuously fed material to make a perpendicular cut without stopping the feed. These applications are used where it isn't practical to stop and start a continuous production operation.

The flying cut-off shown to the right employs four axes of motion:

(1) a rotating pipe cutter,

(2) a continuous pipe infeed system,

(3) carriage positioning drive,

and

(4) outbound conveyor. With the PS-AMC4, all four of these axes can be easily controlled and synchorinized

within the same controller, and it's only $465

Productivity from A to X-Y-Z

When it comes to X-Y-Z positioning, commonly achieved with gantry systems, the PS-AMC motion controller makes it easy. With the PS-AMC, Productivity CPU, and the Multi-Axis Motion Sequencer (MMSEQ) instruction, you can:

- Perform smooth movements between two or more points in up to 3 axes, plus an optional tool axis.

- Easily code For/Next or Do/While loops to repeat portions of the sequence, as desired.

- Iterate through up to 64 steps in a motion sequence, including adding timers and pauses between move actions.

Milling/routing application

When milling or routing materials to match specifications, accuracy is key. Just the slightest misstep during a cut can cause a complete redo and wasted material. Most milling machines utilize three axes of motion (X , Y, and Z axes) and require accuracy that is repeatable time and time again, making these types of applications perfect for ProductivityMotion components.

Precise linear interpolation

A common task in motion control applications is straight line motion. This can be accomplished using multiple axis of motion that work together to perform a linear move from one point to the next. This is also known as linear interpolation. The PS-AMC combined with a Productivity CPU allows you to precisely control each axis so that they all move in unison to reach the target position at the same time; resulting in a straight line from start to finish.

Precise positioning for when close enough just won't cut it

With machinery that uses coordinated motion where one move is dependant on another, especially in situations where a secondary move can only happen once the first has cleared its path, positioning inaccuracies can cause major production loss or even substantial equipment damage. Even small fluctuations can compound and become big issues if not corrected in time. The Productivity AMC has features built-in to compensate for measurement drift and allows on-the-fly position corrections to maintain superior accuracy.

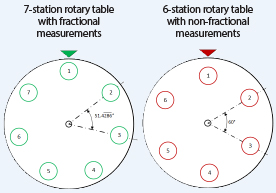

Rotary table applcation

Rotary table applications are very common in manufacturing and can be used to move products into position for drilling, welding, milling, or even for simple tool changes. Behind the scenes, rotary tables aren't very complicated and can be controlled with simple index moves to index the product to the next station or to a specific station.

Depending on the number of stations, one PS-AMC4 may be all you need to handle the rotation of the table, as well as, product placement and station movements.

FREE SOFTWARE!

Download as often as you need. No license of key needed

Stay on target!

One inherent problem with this type of application (as well as other continuous, same direction motion applications), is when the difference between steps/stations is fractional. If the controller doesn't account for these fractions, the system will drift. The PS-AMC controller takes this into consideration and will accurately handle fractional steps to prevent drifting over time and always remain on target.

A-M-C, easy as 1-2-3!

1 - Install Hardware

Once your PS-AMC arrives, install the controller either locally to or remotely from the CPU and connect the needed Ethernet cable(s). Wire up the system, power the controllers and download the free Productivity Suite software to your PC if you haven't already. At this point, you could use the software test tool in Productivity Suite to test the hardware and verify the physical wiring, otherwise on to step 2.

2 - Configure Hardware

With the communication cables connected, and power applied, the Productivity CPU will auto-discover any PS-AMC controllers that are on the same Ethernet network. Once discovered, you can easily set the hardware parameters and modify data tags from within Productivity Suite.

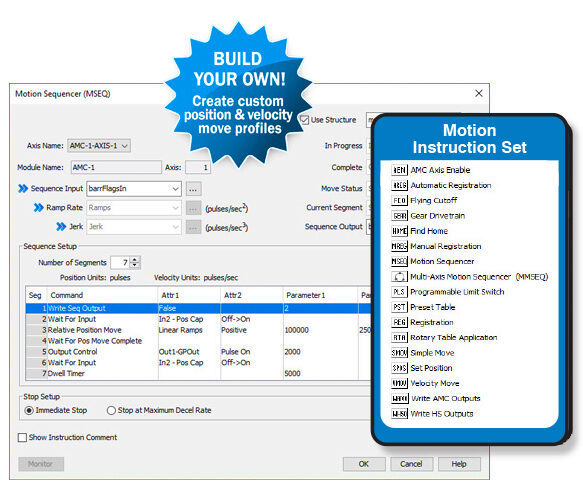

3 - Set Up Motion Profile

Productivity Suite has numerous built-in motion instructions that allow you to quickly and easily configure standard motion profiles like flying cut off, rotary tables and more using simple drop-down selections. If you need something different, you can also create your own custom move profiles using the Motion Sequencer (MSEQ) instruction. Create your profile, download the updated project file to the CPU and you are done!

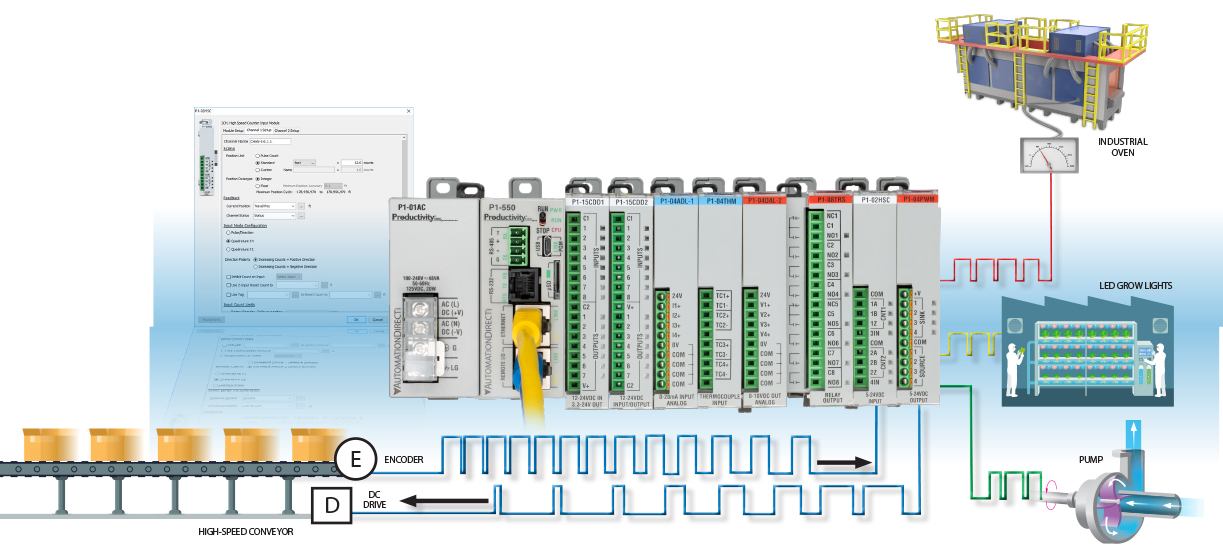

Get the control you need for less with Productivity

Productivity1000 PLCs have low-cost specialty modules to tackle specific functions that are out of the realm of standard I/O modules. High-speed input counting and pulse width modulated outputs are capabilities provided by these modules for applications that require a little more than generic I/O.

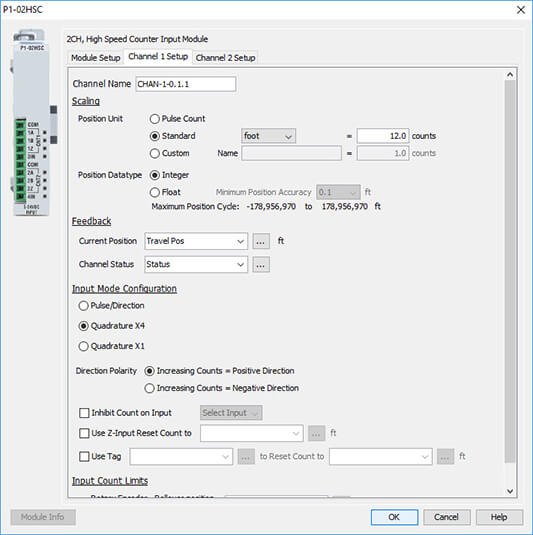

Setup is a cinch!

ProductivitySuite makes it easy to configure your specialty modules. Simply use the convenient fill-in-the-blank GUI to pick the functions you desire, set the scaling (standard or custom), assign the appropriate tags or create them on the fly, it couldn't be any easier.

High-speed Counter (HSC)

The P1-02HSC is capable of handling input pulse frequencies up to 100kHz. Easily count and/or calculate pulse rates from dedicated inputs or encoder signals that are used in many applications including package tracking and picking systems. Additionally, there are two general purpose inputs for use as 5-24 VDC inputs.

Pulse Width Modulation (PWM)

The P1-04PWM pulse width modulation module provides four channels of sinking or sourcing 0-20 kHz, 0-100% duty cycle outputs. The varying pulse widths produced by the PWM module are seen as varying power levels to the end device and are ideally suited for running motors/pumps, controlling LED lighting, opening/closing solenoid valves and more.

Check out our job openings

Free Online PLC Training

FREE Video Tutorials

FREE e-Newsletter

Automation Notebook

Product Literature

White Papers

News, Product and Training Bulletins

E-Books

Safe &

Secure

Safe &

Secure

We accept VISA, MasterCard, Discover, American Express, PayPal or company purchase orders.

Voted #1 mid-sized employer in Atlanta

Check out our

job openings

Loading...

Loading...