Cookies are not enabled on your browser.

Cookies are not enabled on your browser.Cookies are required for our site. Please enable cookies in your browser preferences to continue.

- Barcode / RFID / Vision

- Bulk Wire & Cable

- Cables (Terminated)

- Circuit Protection / Fuses / Disconnects

- Communications

- Drives & Soft Starters

- Enclosure Thermal Management & Lights

- Enclosures & Racks

- Field I/O

- HMI (Human Machine Interface)

- Hydraulic Components

- Motion Control

- Motor Controls

- Motors

- Pneumatic Components

- Power Products (Electrical)

- Power Transmission (Mechanical)

- Process Control & Measurement

- Programmable Controllers

- Pushbuttons / Switches / Indicators

- Relays / Timers

- Safety

- Sensors / Encoders

- Stacklights

- Structural Frames / Rails

- Tools & Test Equipment

- Valves

- Water (Potable) Components

- Wire & Cable Management

- Wire & Cable Termination

- Retired Products

Configuration Utilities

- PLC Family Selector

- P1000 PLC Systems

- P2000 PLC Systems

- P3000 PLC Systems

- ProductivityCODESYS

- CLICK PLC Systems

- Do-more® BRX PLC Systems

- LS-Electric® XGB PLC Systems

- Productivity®Open Systems

- Datalogic® Safety Light Curtains

- LS-Electric® Servo Systems

- Nitra® Pneumatic Grippers

- Object Detection (Sensors)

- PAL Controller Configurator

- Precision Gearbox Selector

- Protos X® Field I/O

- Pyrometers Selector

- Quadritalia® Modular Enclosures

- Stellar® Soft Starters

- Stepper System Selector

- SureFrame T-slot Extrusion

- SureMotion® XYZ Gantry

- SureServo2® System Selector

- SureStep® Linear Actuators

- Timing Belts & Pulleys

- Werma® Stacklights

- ZIPLinks

Machine Control

Wide Variety of I/O Modules

Productivity2000 offers 8-point and 16-point versions of the DC discrete inputs and discrete outputs (in sinking or sourcing), and 8 or 16-point AC modules, relay outputs and Specialty Modules (including High-Speed I/O Modules and motion controllers). Analog Inputs, Outputs, and Combination modules are also available - all with 16-bit resolution. Click a module below to see the full range of each type.

Analog Inputs

4, 8 or 16-point; voltage, current, RTD, and thermocouple. 16-Bit resolution.

Prices start at $217.00

Analog Outputs

4, 8 or 16-point; voltage or current; sinking or sourcing. 16-bit resolution.

Prices start at $212.00

Analog Combos

Combination of analog inputs and outputs on the same module. 16-bit resolution.

Prices start at $456.00

Motion & High Speed

2 Channel High-Speed Input, 2 Channel High-speed Output, 2 Channel High-speed Counter, and 4 Channel Pulse Width Modulation Module.

Prices start at $120.00

Specialty & Communications

4-port Serial Modules

Prices start at $242.00

Motion Controllers up to 4 axes, 1 MHz maxiumum switching frequency, up to 24 high-speed input points, 4 differential encoder inputs, 12 high-speed output points, and 4 differential output.

Prices start at $331.00

Remote and Field I/O Made Simple

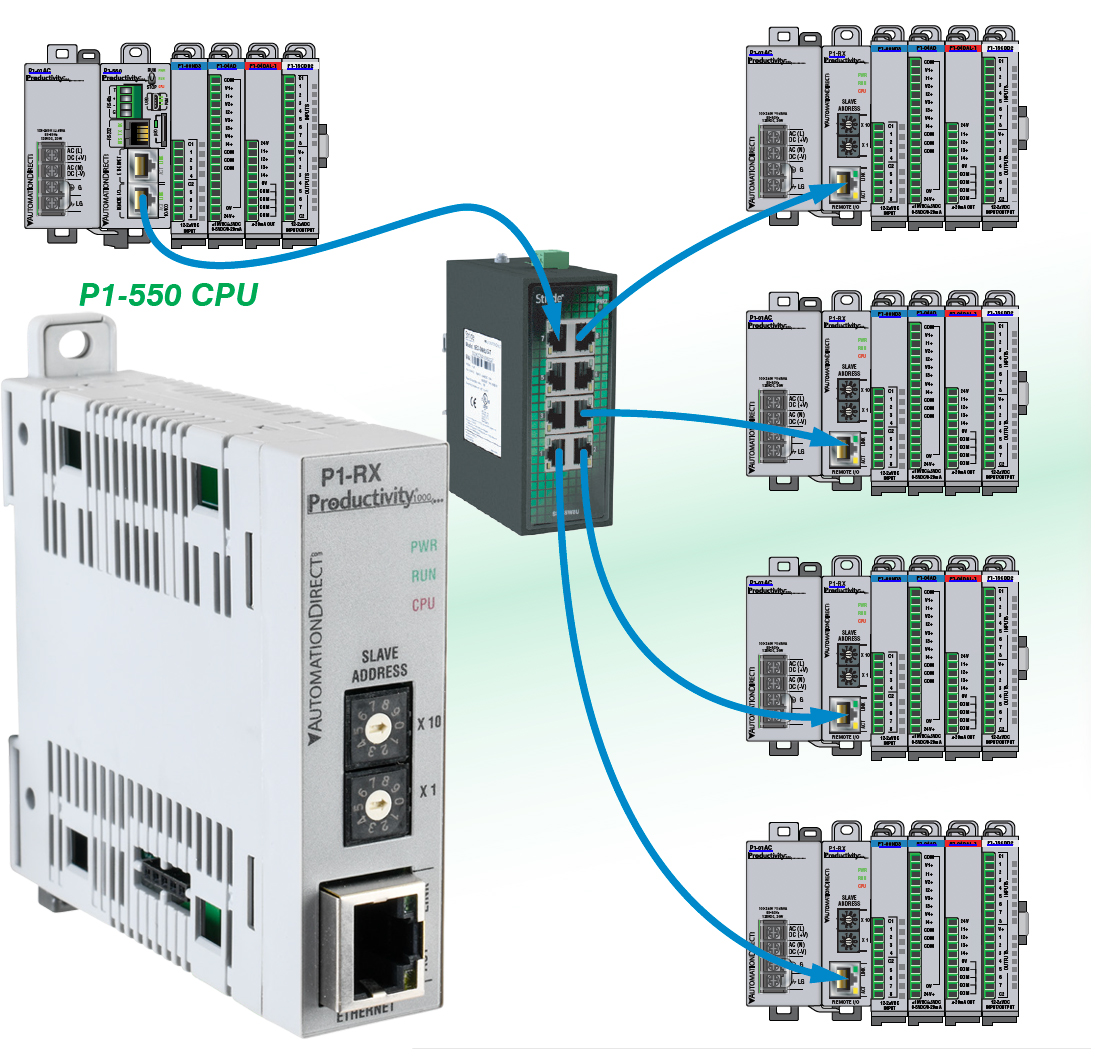

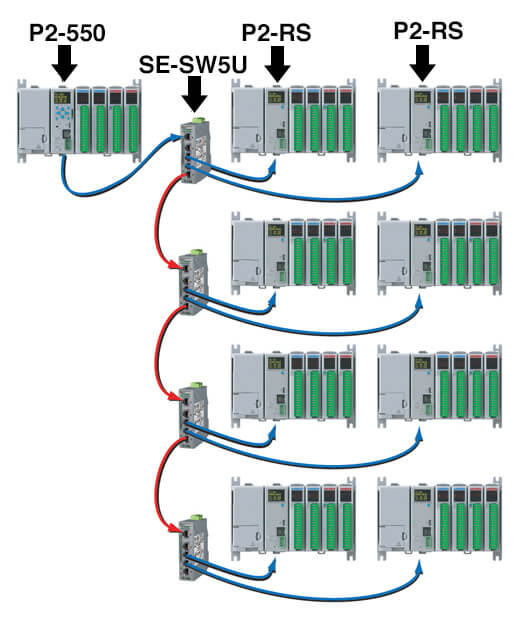

Add up to 8 remote racks

Create a Remote I/O rack by simply installing a P1-RX or P2-RS Remote Slave module in the controller slot of an additional rack. Connect the remote racks to the master with standard Ethernet patch cords and switches. The Productivity2000 master will auto-detect all the I/O, and will create the physical I/O tags automatically. You are free to use the auto-configured settings or adjust them manually.

Access over 4000 I/O points in a single Productivity2000 system

Install remote I/O racks wherever you need them! In the main enclosure when you have a large local I/O count, OR distribute remote racks to be closer to the actual I/O devices to minimize wiring length, complexity, AND COST. Mount remote racks at the other end of a machine, the other side of the plant floor, or in another building - and wire a single Ethernet cable back to the Master!

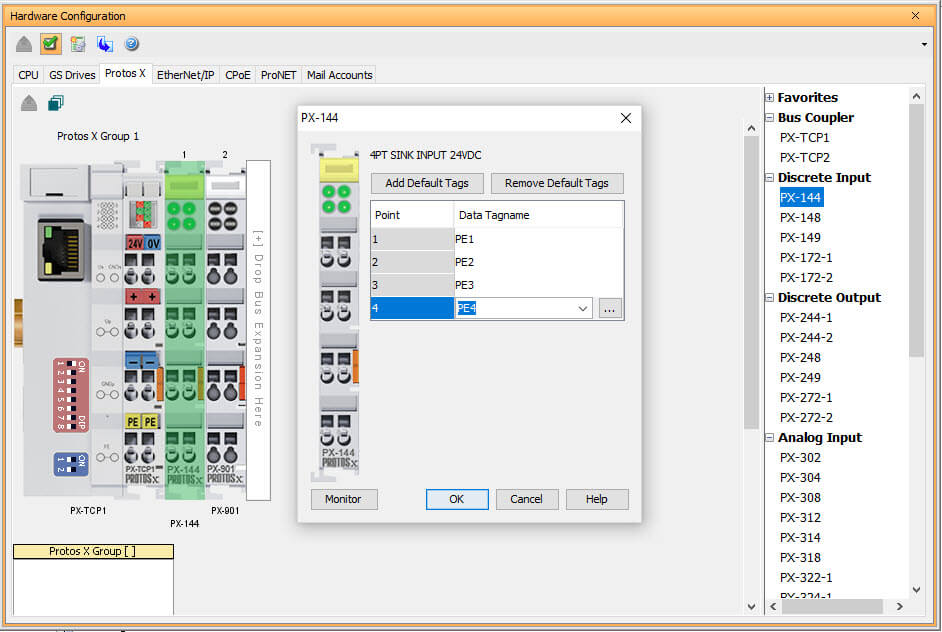

Integrated field I/O

The Productivity Suite software will auto detect the Protos X field I/O system (using a Modbus coupler) connected to the Remote I/O port of the P2-550 and automatically assign tags to the installed I/O terminals. The configuration can be manually changed and it is saved within the PLC project.

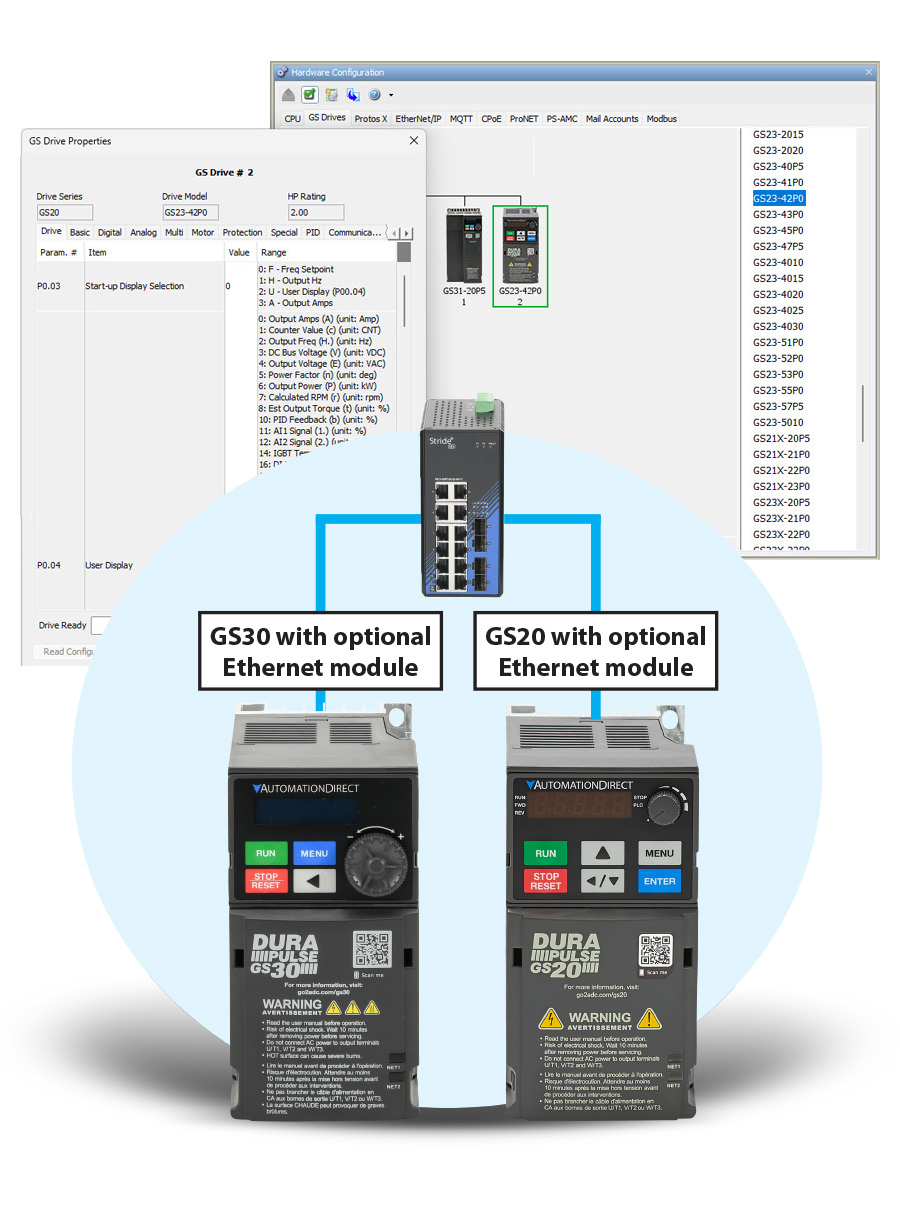

7. VFDs can be set up in seconds

The Productivity2000 programming software is designed to recognize any AutomationDirect GS series drive. Simply connect the drive to the remote I/O port via its Ethernet connection and it is discovered in the Productivity Suite software. And no more searching through drive manuals to find the parameter you need. Each parameter, with description, range, and value, is available in the software. These parameters can be read from, edited, or written to the drive right from the Productivity Suite Hardware Configuration, making initial setup almost too easy! Store all of your drive parameters in the CPU for safekeeping and communicate to your drives with simple read/write instructions in the software. This can save you hours of time.

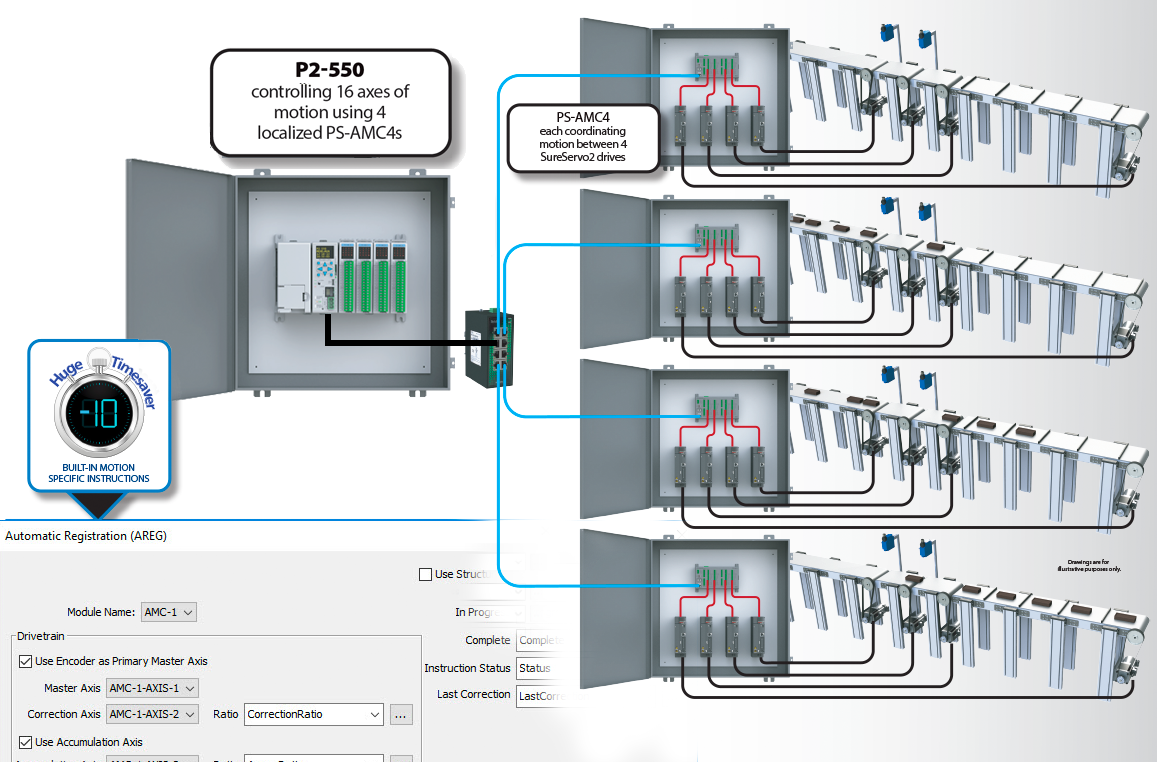

Easy control up to 16 axes of motion across your facility

Each remote I/O capable Productivity2000/3000 CPU can control up to 16 axes using four PS-AMC4 controllers each coordinating up to four axes on their own (P1000 systems can control up to 4 axes using 1 PS-AMC controller). So whether you have a single system with 4 or more axes of motion, multiple coordinated systems across your facility, or if you're anticipating future expansion, the PS-AMC is a perfect solution for your motion application.

The Productivity Suite software provides the following for the PS-AMC:

- Motion profile set-up with easy-to-use built-in motion instructions

- Software test tool allows you to test the hardware without any ladder code & very useful for validating the physical wiring

- Real-time status and diagnostic information

- Plug-and-play hardware configuration using auto-discovery of the AMC units

Smart conveyor application

When it comes to package handling, pick-and-place or similar applications, product spacing is very important. One way to ensure proper spacing is to send the products through a smart conveyor system. With a smart conveyor, products arriving from an upstream process are brought to the right distance and phase position using several belts that are electronically coupled with each other through a PS-AMC controller. Each conveyor's servo motor will speed up or slow down to achieve the appropriate spacing between products. Four coordinated four-belt smart conveyor systems can be controlled with just one CPU.

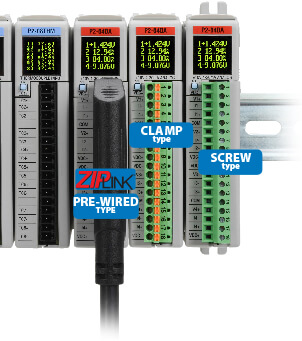

9. Choose the wiring option YOU prefer

Productivity2000 is all about productivity, even down to the wiring. Three wiring options are available to better serve the specific needs of your application. Two terminal blocks; one screw type, and one clamp type are available, as well as our ZIPLink wiring system. Why spend the time wiring each I/O point to a terminal when you can get them prewired? ZIPLink pre-wired cables and terminals not only save you valuable time but also keep your installation clean and efficient, which helps when troubleshooting, and ZIPLinks use half the space at a fraction of the cost of standard terminal blocks. Simply snap the ZIPLink connector to the I/O module, connect your field wiring to the ZIPLink terminal and your wiring job is done.

AutomationDirect strongly recommends the use of ZIPLink cables and wiring modules, which eliminate the need for hand wiring of I/O modules to terminal blocks. In fact, many of the Productivity2000 I/O modules do not include the terminal blocks for direct connection of I/O.

Note: ZIPLinks are available for most, but not all I/O modules.

ZIPLink Module

ZIPLink Pre-Wired

ZIPLink Pigtail Cable

Perfect match for C-More HMIs!

Export your tagname database from the Productivity CPU and import it into your C-more HMI Panel to jumpstart your HMI development. No more digging through your notes, or hunting through your ladder logic to find the right tagname.

Connect up to 16 C-more HMIs to the Productivity CPU via Ethernet for control and visibility of your process/machine from anywhere in your factory. Use the remote access feature of C-more to view (and possibly control) your system from anywhere via the Internet. C-more offers a wealth of productive features that make it a perfect match for the Productivity2000. More about C-more here.

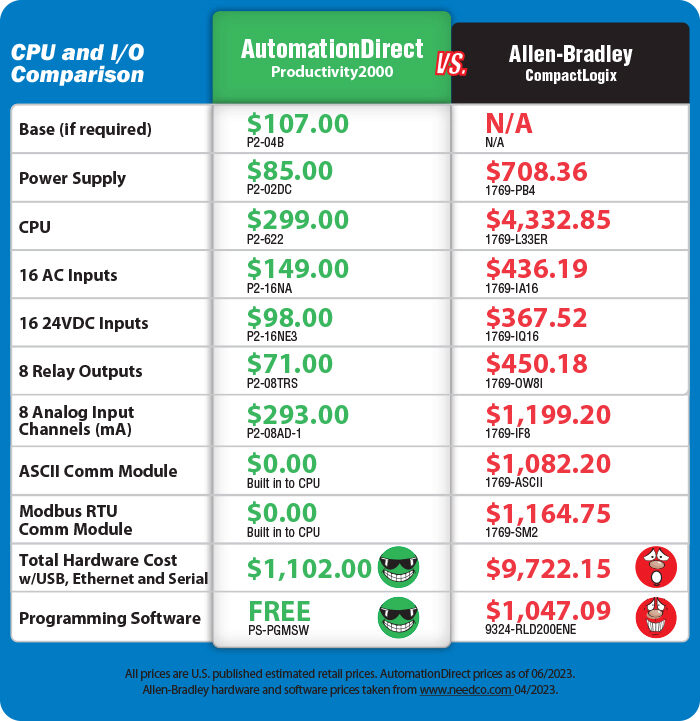

1. Our CPU is under $400.00 . . . Theirs is over $5,000.00!

The Productivity2000 PLC was designed to offer you the lowest cost of ownership in its class. Compare our P2000 PLC CPU (P2-622) to an Allen Bradley CompactLogix PLC CPU (5069-L320ER).

The $5,132.35 (list price) Allen Bradley CPU offers 2MB of user memory, a 32GB SD card slot, three communications ports, and LED CPU status indicators. Of course, you will also need to purchase programming software for the Allen Bradley CPU which can cost thousands.

The $302.00 (everyday price) AutomationDirect P2-622 CPU offers 50MB of built-in memory, a removable micro SD card slot (up to 32GB of data storage and portable program downloads), 5 built-in communications ports, and a high-resolution display with LED status indicators also. Our programming software (developed inhouse) is FREE with no annual licensing or support fees. Download as many copies as you want. On top of that, you'll also get our FREE unlimited phone-in technical support which has received numerous service awards.

Here are a few of the top CPU features:

- Plug-and-play USB programming (no converter cable needed)

- Tag database and program documentation storage on-board the CPU!

- Up to 2 High-speed Ethernet ports for HMI and peer or enterprise networking (no separate Ethernet communications module needed)

- Two serial ports for peripheral device interface or controller networking (no separate serial port or ASCII module needed)

- USB data logging to microSD card right on the CPU

- Programmable 4-line OLED for short message display (including tag data)

- Secure Web Server for fast easy access to your data!

It's all built-in!

Check out our job openings

Free Online PLC Training

FREE Video Tutorials

FREE e-Newsletter

Automation Notebook

Product Literature

White Papers

News, Product and Training Bulletins

E-Books

Safe &

Secure

Safe &

Secure

We accept VISA, MasterCard, Discover, American Express, PayPal or company purchase orders.

Voted #1 mid-sized employer in Atlanta

Check out our

job openings

Loading...

Loading...