Cookies are not enabled on your browser.

Cookies are not enabled on your browser.Cookies are required for our site. Please enable cookies in your browser preferences to continue.

We will close at 3PM ET on Tuesday, December 23rd. Please note our shipping changes for Tuesday.

Freight shipments, FedEx ground and customer pickup deadline is 11:00AM ET. FedEx Priority (and free 2-day delivery) cutoff will be 1:00 PM ET. No UPS shipping will be available on Tuesday.

Drop ship vendors, Saginaw, Husky and Weigmann will also be closed Friday, Dec 26th.

Merry Christmas to each of you and your families from the employees of AutomationDirect

- Barcode / RFID / Vision

- Bulk Wire & Cable

- Cables (Terminated)

- Circuit Protection / Fuses / Disconnects

- Communications

- Drives & Soft Starters

- Enclosure Thermal Management & Lights

- Enclosures & Racks

- Field I/O

- HMI (Human Machine Interface)

- Hydraulic Components

- Motion Control

- Motor Controls

- Motors

- Pneumatic Components

- Power Products (Electrical)

- Power Transmission (Mechanical)

- Process Control & Measurement

- Programmable Controllers

- Pushbuttons / Switches / Indicators

- Relays / Timers

- Safety

- Sensors / Encoders

- Stacklights

- Structural Frames / Rails

- Tools & Test Equipment

- Valves

- Water (Potable) Components

- Wire & Cable Management

- Wire & Cable Termination

- Retired Products

Configuration Utilities

- PLC Family Selector

- P1000 PLC Systems

- P2000 PLC Systems

- P3000 PLC Systems

- ProductivityCODESYS

- CLICK PLC Systems

- Do-more® BRX PLC Systems

- LS-Electric® XGB PLC Systems

- Productivity®Open Systems

- Datalogic® Safety Light Curtains

- LS-Electric® Servo Systems

- Nitra® Pneumatic Grippers

- Object Detection (Sensors)

- PAL Controller Configurator

- Precision Gearbox Selector

- Protos X® Field I/O

- Pyrometers Selector

- Quadritalia® Modular Enclosures

- Stellar® Soft Starters

- Stepper System Selector

- SureFrame T-slot Extrusion

- SureMotion® XYZ Gantry

- SureServo2® System Selector

- SureStep® Linear Actuators

- Timing Belts & Pulleys

- Werma® Stacklights

- ZIPLinks

Motion Control

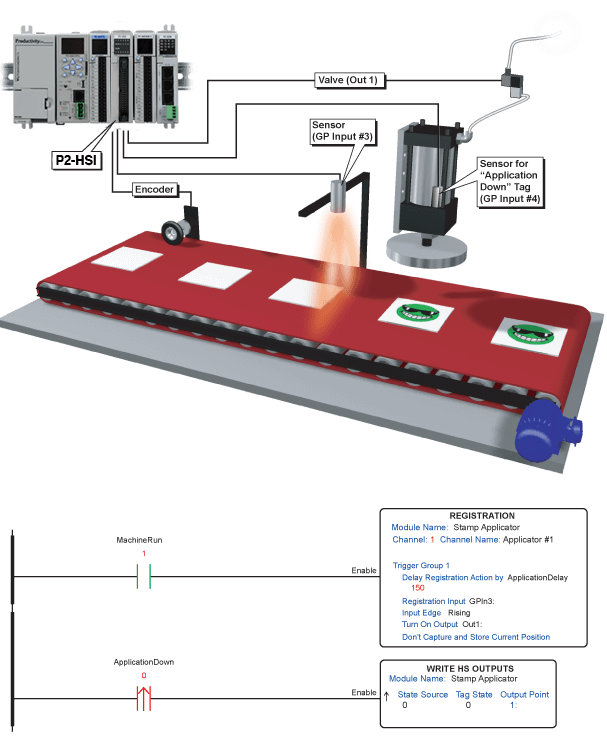

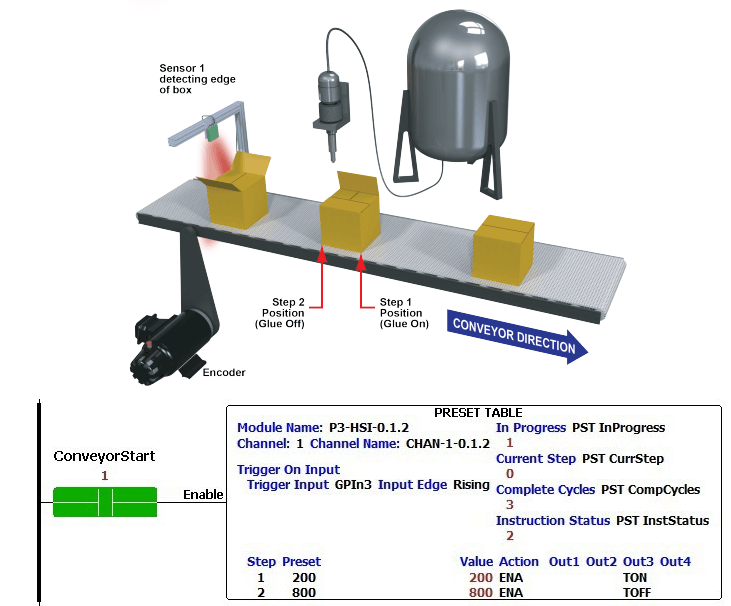

Registration (using P2-HSI)

Use the P2-HSI High-Speed Input Module for registration.

In this example, a High Speed Input (P2-HSI) module is used to accurately stamp parts as they move past on a conveyor. A blank part is detected by the sensor and the instruction is triggered. The output or stamping function is delayed by the appropriate number of encoder pulses. Once the part travels to the precise location under the stamp, the pneumatic stamp is activated and the image is stamped onto the magnet. The encoder pulse train can be up to 1Mhz - faster than the scan time of the Productivity2000. This is critical for accurate operation in this application.

P2-HSI

$288.00

The P2-HSI is a High-Speed (1MHz) input module that has both differential and single ended inputs. This module accepts Pulse/Direction and Quadrature signals on each of two independent input channels. It also provides four general purpose high-speed inputs and four general purpose 5-24VDC @ 0.5 Amp outputs.

The P2-HSI High-Speed Input Module can be used for:

High-Speed Counting

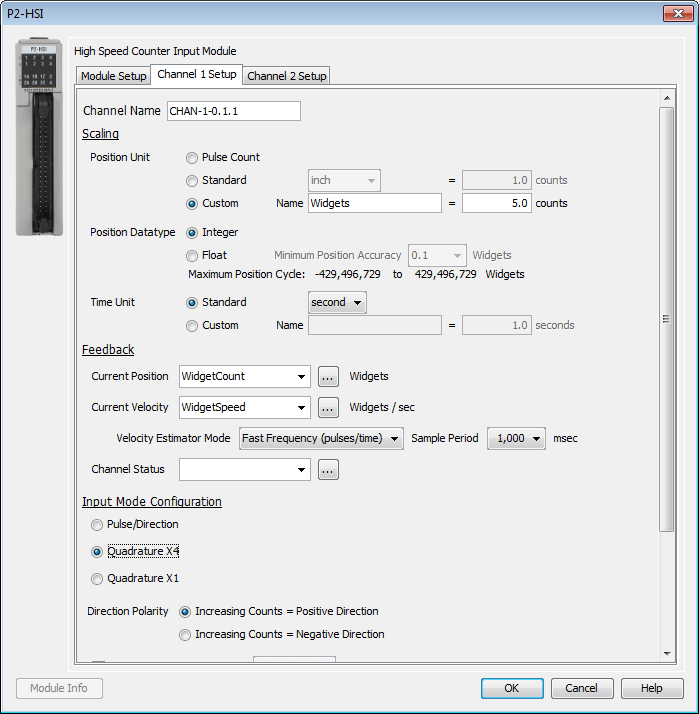

Use the P2-HSI High-Speed Input Module for high-speed counting, with discrete inputs or encoders.

The High Speed Input (P2-HSI) module can be configured for high-speed pulse counting and/or encoder input in the hardware configuration dialog shown below. Simply define your tags for each input channel on the Channel Setup Tab. You can even specify custom units, and take advantage of an estimated velocity function. In this example a quadrature encoder is supplying a high-speed pulse train with 5 pulses for each "widget" as it moves through the machine (with custom scaling of 1 Widget = 5 encoder counts). Once this is configured, you can now accurately monitor the user defined tags for "WidgetCount", and "WidgetSpeed" (in widgets/sec) in the ladder logic program even though the encoder counts (and "WidgetCount") may be counting at a faster rate than the scan time of your ladder-logic program.

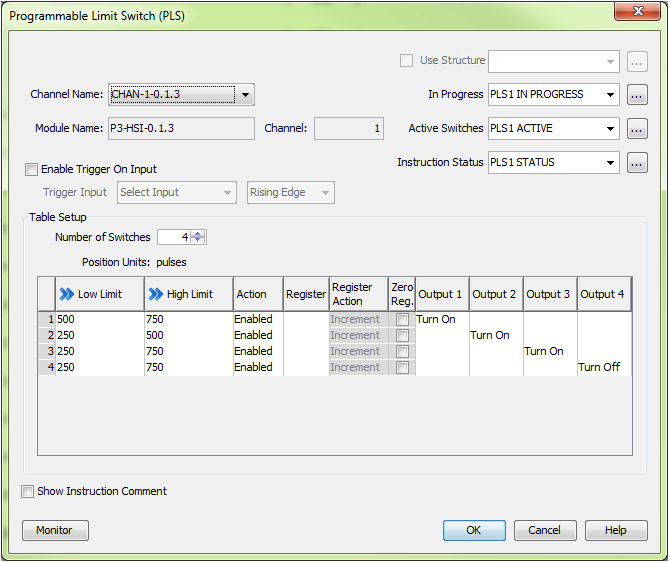

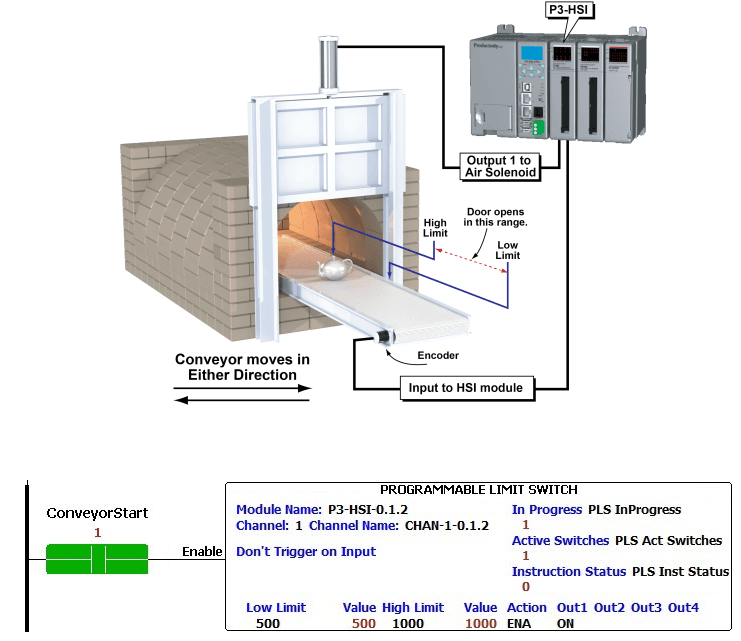

Programmmable Limit Switch (using P2-HSI)

NEW with Productivity Suite version 2.1.0.16

Use the P2-HSI High-Speed Input Module to create virtual limit switches with the Programmable Limit Switch (PLS) instruction.

The basic purpose of a Programmable Limit Switch (PLS) Instruction is to switch discrete outputs ON or OFF based on the position of an encoder's rotating shaft. The PLS instruction replicates the functionality of a mechanical "multi-channel" rotary cam switch.

- The PLS instruction allows 16 Switches to control up to 4 outputs built into the P-Series High Speed Input module.

- The high and low limits for each switch define a range at which a given output turns ON or OFF, and are defined by the table within the instruction.

- The range defined for one switch may overlap with the ranges for other switches.

- Actuation of the switches is independent of the direction of travel of the encoder shaft.

- A bit field status register "Active Switches" is available to determine the state of any of the 16 switches in your ladder code.

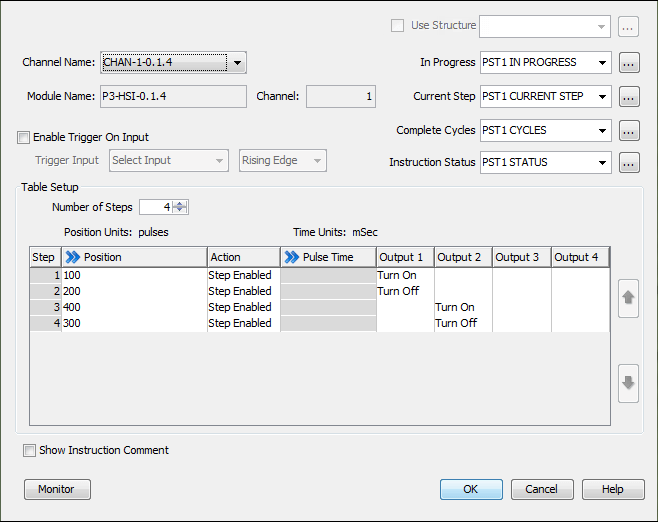

Preset Tables (using P2-HSI)

NEW with Productivity Suite version 2.1.0.16

Use the P2-HSI High-Speed Input Module to create Preset Tables.

Like the Programmable Limit Switch Instruction, the Preset Table Instruction (PST) also switches discrete outputs ON or OFF based on the position of a rotary encoder but it functions (and is programmed) more like a drum instruction.

- When a table position value (a "step") is reached, that step becomes complete and the associated outputs are set to the desired state.

- The PST instruction is then only concerned with the Next Step as defined in the table.

- Even if the position count drops below the table position value in the Current Step, the outputs will not change states.

- The PST instruction initiates state changes ONLY when the next position value (step) is reached regardless of direction of travel.

- Like a Drum instruction, the Preset Table Instruction maintains a "Current Step" register that may be accessed from your ladder code.

Flexible Homing Routines

The Find Home (HOME) instruction allows the user to run a variety of homing routines. Homing is used to align the P2-HSO channel position to a known real-world physical position. Generally homing is only necessary on power-up of a machine that incorporates incremental positional feedback. Homing may also be required at other times depending on the application.

The following example demonstrates how the Find Home (HOME) instruction can be utilized in a Pick and Place application. When the instruction is enabled, the gantry arm will accelerate to the 'First Speed' and travel at that speed until Switch #1 is triggered. The gantry arm will then decelerate to the 'Second Speed' selection and travel at that speed until Switch #2 is triggered. Once Switch #2 is triggered, the gantry arm will stop, and the home move is complete. The use of a high-speed "seeking" move, followed by a much slower "creeping" move, allows for a fast and accurate home procedure.

Note: When controlling a servo system - such as SureServo - Switch #1 might be a traditional limit switch, but the "z-pulse" from the SureServo's built-in encoder can be used as Switch #2 for an extremely accurate and repeatable home location.

At the completion of the Find Home operation, the value of the output can be set to a desired value (often 0) to represent the home position. The instruction supports the usual 'Move Status', 'In Progress', and 'Move Complete' flags for monitoring in the ladder-logic program. Note that the home routines are controlled independently by the HSO module, and are not subject to scan time considerations.

P2-HSO

$288.00

The P2-HSO is a High-Speed (1MHz) output module that supports Pulse/Direction, Step Up/Step Down and Quadrature pulse output on each of two independent output channels. It has both line driver and open drain outputs. Additionally, it has six general purpose high-speed inputs and four general purpose outputs

The P2-HSO High-Speed Output Module can be used for various motion control operations including:

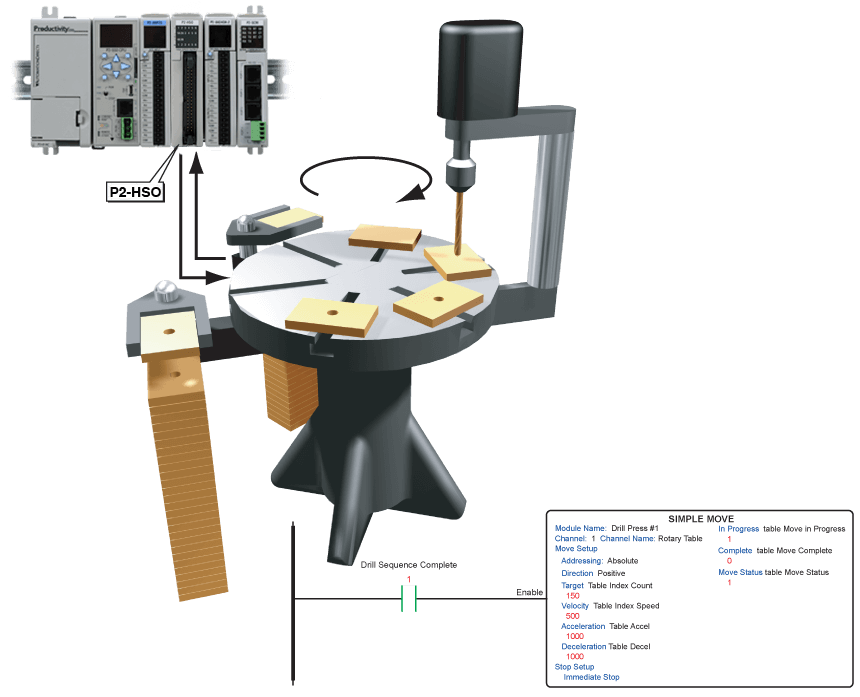

Simple Move

Use the P2-HSO High-Speed Output Module for Simple Moves.

The Simple Move instruction allows precision control of either pulse output channel. You define distance, acceleration and deceleration parameters, and you can start, stop and monitor the motion (pulses) from your ladder logic. The high speed pulse train is produced independently on the HSO module, and is not subject to scan time considerations.

In this example, the Simple Move instruction is used to rotate the rotary table of a switch plate production system. Each blank plate is rotated under the drill press and held there until the plate is drilled. The Simple Move instruction indexes the rotary table the appropriate distance for each new plate. Once drilled, the switch plates are then rotated out and stacked for packaging. The Simple Move instruction allows the user to define various tags for monitoring the process, including 'Move Status', 'In Progress', and 'Complete' flags. An 'Immediate Stop' tag can be defined to stop a move that is in progress.

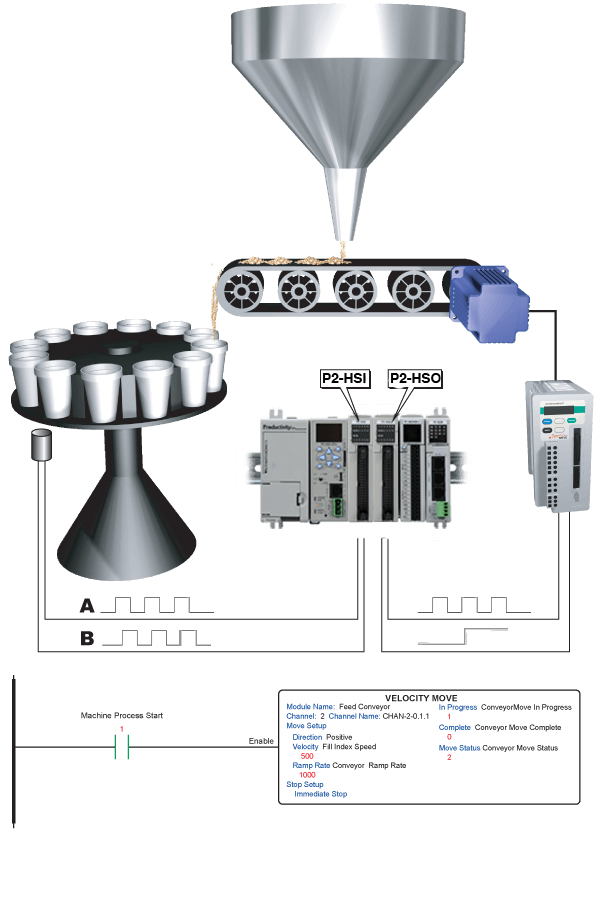

Velocity Move

Use the P2-HSI High-Speed Input Module in conjunction with the P2-HSO High-Speed Output Module to perform a Velocity Move.

The P2-HSI is a High-Speed (1MHz) input module that has both differential and single ended inputs. This module accepts Pulse/Direction and Quadrature signals on each of two independent input channels. It also provides four general purpose high-speed inputs and four general purpose 5-24VDC @ 0.5 Amp outputs.

The Velocity Move (VMOV) instruction allows precision velocity control of a pulse output channel (on P2-HSO module) based on the speed of a high-speed input channel (on P2-HSI module).

In this example, the Velocity Move instruction is used with the P2-HSO module to synchronize the speed of the SureServo driving the fill conveyor. The conveyor is synchronized with the rotational speed of the turntable based on the signal(s) from the table encoder feedback via the P2-HSI. The high speed pulse train is produced independently on the HSO module, and is not subject to scan time considerations.

Check out our job openings

Free Online PLC Training

FREE Video Tutorials

FREE e-Newsletter

Automation Notebook

Product Literature

White Papers

News, Product and Training Bulletins

E-Books

Safe &

Secure

Safe &

Secure

We accept VISA, MasterCard, Discover, American Express, PayPal or company purchase orders.

Voted #1 mid-sized employer in Atlanta

Check out our

job openings

Loading...

Loading...