Cookies are not enabled on your browser.

Cookies are not enabled on your browser.Cookies are required for our site. Please enable cookies in your browser preferences to continue.

- Barcode / RFID / Vision

- Bulk Wire & Cable

- Cables (Terminated)

- Circuit Protection / Fuses / Disconnects

- Communications

- Drives & Soft Starters

- Enclosure Thermal Management & Lights

- Enclosures & Racks

- Field I/O

- HMI (Human Machine Interface)

- Hydraulic Components

- Motion Control

- Motor Controls

- Motors

- Pneumatic Components

- Power Products (Electrical)

- Power Transmission (Mechanical)

- Process Control & Measurement

- Programmable Controllers

- Pushbuttons / Switches / Indicators

- Relays / Timers

- Safety

- Sensors / Encoders

- Stacklights

- Structural Frames / Rails

- Tools & Test Equipment

- Valves

- Water (Potable) Components

- Wire & Cable Management

- Wire & Cable Termination

- Retired Products

Configuration Utilities

- PLC Family Selector

- P1000 PLC Systems

- P2000 PLC Systems

- P3000 PLC Systems

- ProductivityCODESYS

- CLICK PLC Systems

- Do-more® BRX PLC Systems

- LS-Electric® XGB PLC Systems

- Productivity®Open Systems

- Datalogic® Safety Light Curtains

- LS-Electric® Servo Systems

- Nitra® Pneumatic Grippers

- Object Detection (Sensors)

- PAL Controller Configurator

- Precision Gearbox Selector

- Protos X® Field I/O

- Pyrometers Selector

- Quadritalia® Modular Enclosures

- Stellar® Soft Starters

- Stepper System Selector

- SureFrame T-slot Extrusion

- SureMotion® XYZ Gantry

- SureServo2® System Selector

- SureStep® Linear Actuators

- Timing Belts & Pulleys

- Werma® Stacklights

- ZIPLinks

Software Features

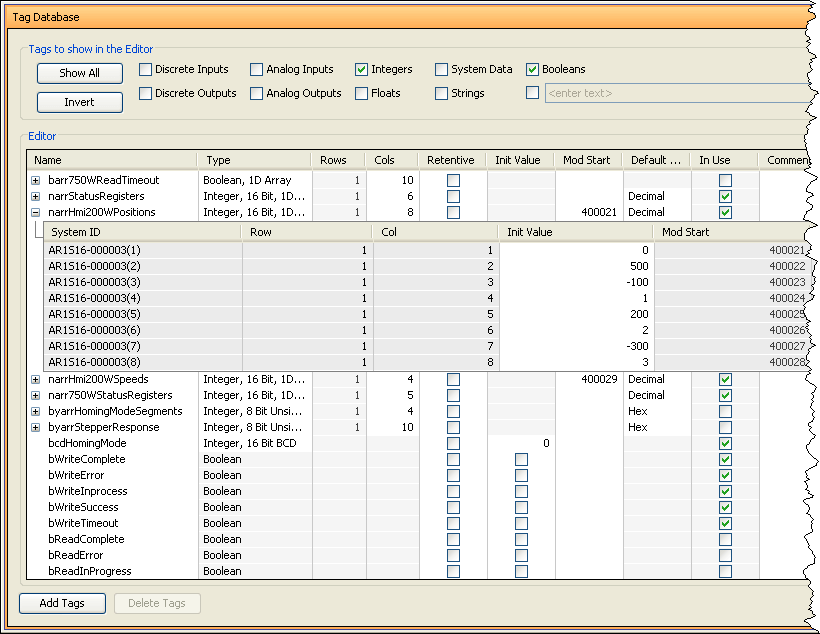

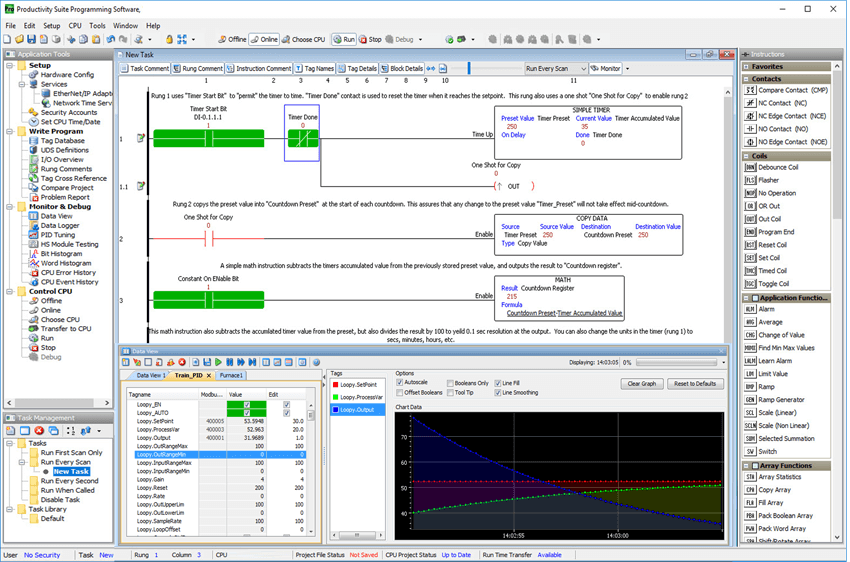

Tagname Based Programming

Reference your variables and I/O points with sensible names (tagnames) and make your program easier to understand. Add descriptive names as you program or enter all the tags before you even write one line of code.

Data memory ranges in the Productivity Suite are not fixed by data type. This efficiency allows you the freedom to define tagnames of any data type you need instead of having arbitrary blocks of wasted memory for data types you don't need.

While the Productivity Suite offers you the option to assign a logical name to your physical I/O points automatically when a module is selected (or auto-discovered) , you can replace or augment these numerical rack, module, and point references with your own descriptive names at any time.

Export (and Import) your entire tagname database:

Perhaps you wish to connect to a C-more HMI Panel, or create a PC based HMI/SCADA system with Point-of-View. You can export your entire tagname database, and import it into the HMI software – saving hours of typing and hunting for the correct tagname – and eliminating typographical errors that cause needless troubleshooting headaches.

Or maybe you would like to edit your tag database in a spreadsheet format – simply export it to .CSV format, make your changes, and then import the changes back into the Productivity Suite.

Benefits of a tagname based controller

More descriptive naming:

- When creating tags, you're essentially documenting your process.

More flexible design

- You decide how the memory is defined. Timer, Counters, Floating point values, signed or unsigned integers, internal registers, etc. You are not restricted by the boundaries or "memory map" set forth by the vendor for each fixed address controller.

Easier to troubleshoot:

- X15, I:4/3, C200, B3:0/2 mean very little with respect to your process or machine...

- However, 'System Start_PB1', 'Auto Mode_SW1' or 'Batch Seq_Enabled' are very clear and concise.

- These are common descriptors (or labels) that are added to a fixed-memory address (or used as a "comment") in non-tagname based systems.

- A tagname based controller simply incorporates these descriptions/labels as the Tagname.

Better naming conventions result in an easier to understand and better documented program.

Shared tag name database:

- Create once, then use it multiple times. This results in huge time savings.

- Import/export to a .csv file for easy editing and share w/ HMI, SCADA, etc. to eliminate an additional step in your development process.

- No complex calculations to determine Modbus addresses. With a tag name controller, you assign them as you need them.

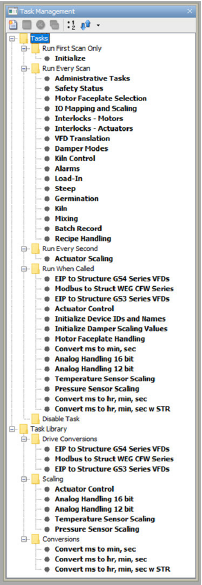

Powerful Task Manager

Have you ever had to write custom ladder logic to get a section of code to only execute periodically and not every scan? Or what about ladder code that only needs to run on the first scan?

With the Productivity Suite Task Manager you simply break up your ladder logic into separate tasks and then drag them into the appropriate categories. In the diagram below the task (or ladder logic routine) Setup and Initialization has been placed in the "Run First Scan Only" category, and will only execute once at start-up.

Combined with the ability to make run-time edits , the Task Manager is a powerful coding and debugging tool. Keep a task in the "disabled" category while you are developing it, and then drag it into the "Run Every Scan" to test it. Place data collection and other periodic tasks in the "Run Every Second" category and improve the scan time of your main routine.

Give it a try - we think you'll agree - the Task Manager offers true productivity enhancement.

Mouse over the Task Management window tasks below:

Run First Scan Only:

Any task in this folder will be executed (scanned) on the First Scan after a run mode power-up and/or a Stop-to-Run mode transition.

Run Every Scan:

Any task in this folder will be executed (scanned) every scan, as long as the CPU is in Run mode with no errors.

Run Every Second:

For lower priority tasks that do not need to run every scan, a task in this folder will be executed (scanned) every 1 second, as long as the CPU is in Run mode with no errors.

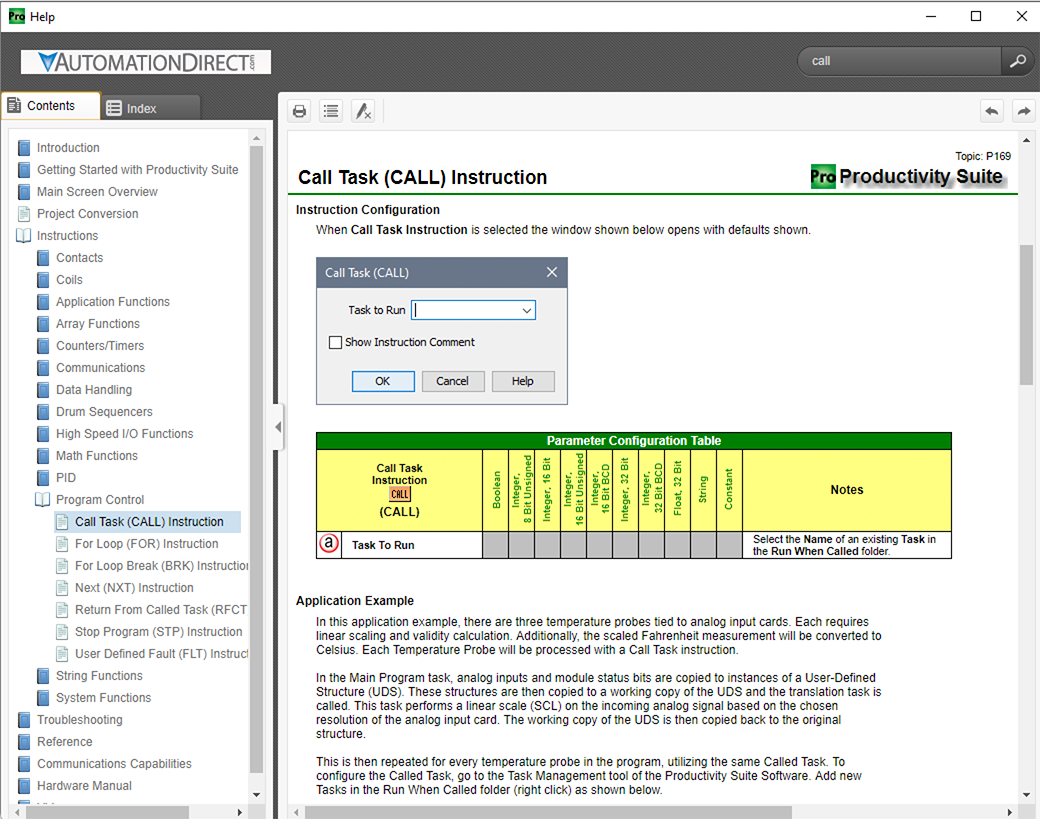

Run When Called:

For tasks that need to be executed (scanned) on an event or time base. A task in this folder must be called to run by a "Call Task" instruction.

Disable Task:

Any task placed in this folder will not be executed (scanned). This can be especially useful during testing and debug.

Perfect match for C-More HMIs!

Export your tagname database from the Productivity CPU and import it into your C-more HMI Panel to jumpstart your HMI development. No more digging through your notes, or hunting through your ladder logic to find the right tagname.

Connect up to 16 C-more HMIs to the Productivity CPU via Ethernet for control and visibility of your process/machine from anywhere in your factory. Use the remote access feature of C-more to view (and possibly control) your system from anywhere via the Internet. C-more offers a wealth of productive features that make it a perfect match for the Productivity2000. More about C-more here.

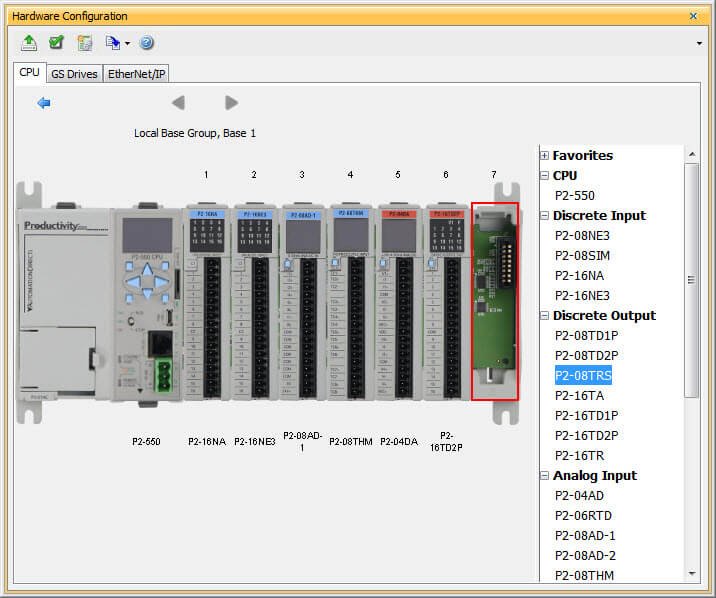

6. Get started in seconds with auto-discovered I/O modules

Simply clip each I/O module into the base and power up. The P2000 will automatically discover the modules and create a realistic picture of your configuration in the free Productivity Suite software. Physical I/O tags will be generated based on each module's position in the base and that's it! You are ready to program with the auto-configured settings just seconds after power-up, or you can reconfigure the setup and assign new tags manually.

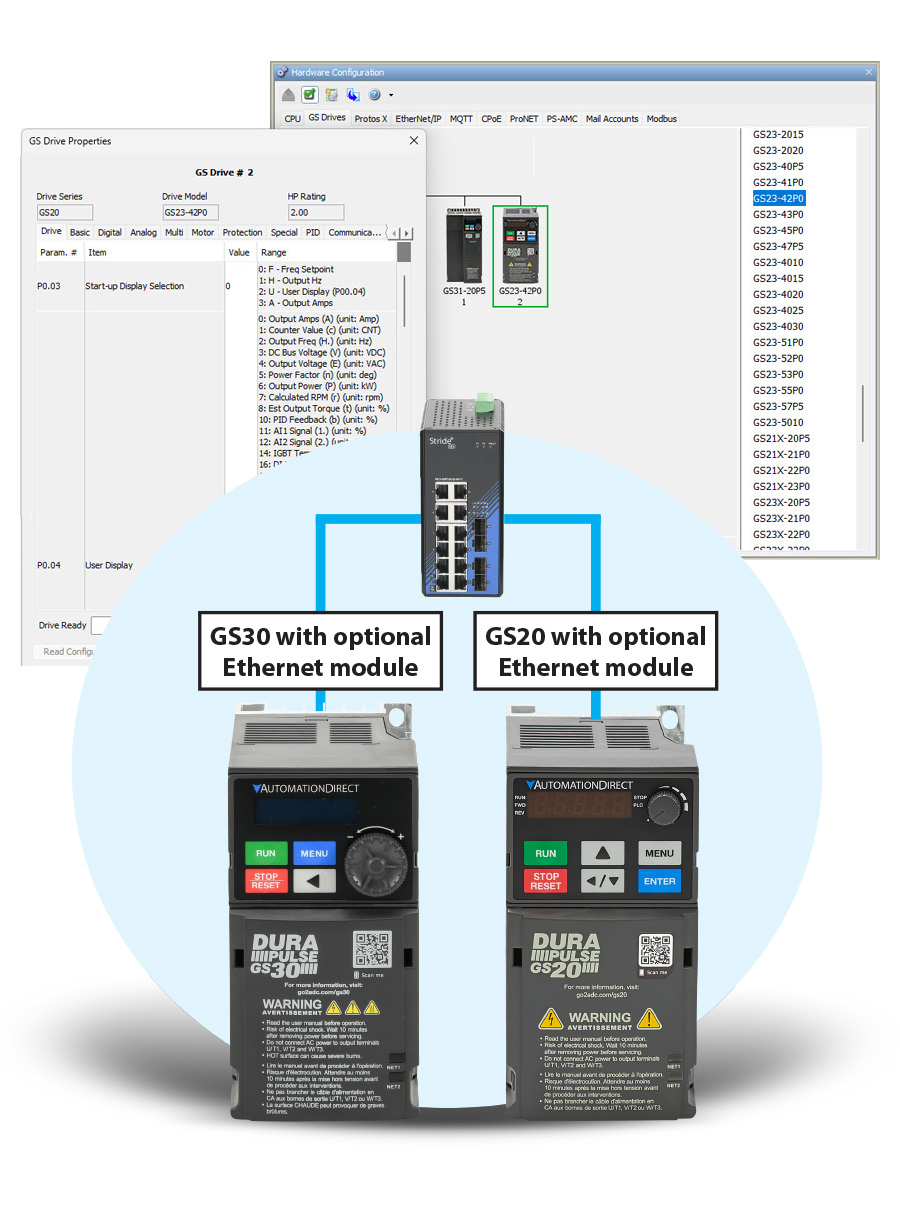

7. VFDs can be set up in seconds

The Productivity2000 programming software is designed to recognize any AutomationDirect GS series drive. Simply connect the drive to the remote I/O port via its Ethernet connection and it is discovered in the Productivity Suite software. And no more searching through drive manuals to find the parameter you need. Each parameter, with description, range, and value, is available in the software. These parameters can be read from, edited, or written to the drive right from the Productivity Suite Hardware Configuration, making initial setup almost too easy! Store all of your drive parameters in the CPU for safekeeping and communicate to your drives with simple read/write instructions in the software. This can save you hours of time.

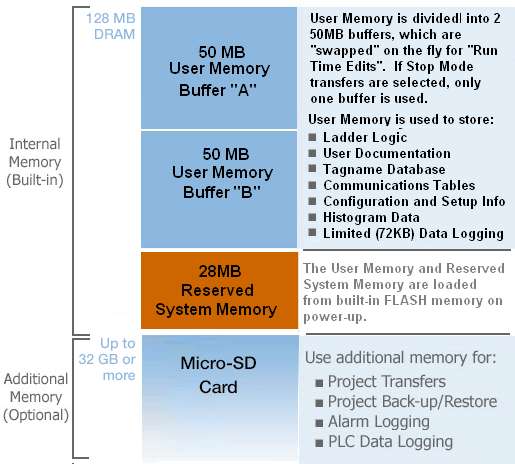

50Mb of User Memory

Store your entire project with ALL documentation in the CPU, and never hunt for that old laptop again. You know, the only one that has the updated code from last summer when you made all those changes.

Sure, we recommend that you make a back-up, but who hasn't been burned by this classic PLC problem?

Now you can download the free software to any available PC, grab the project (with documentation) from the Productivity CPU and you can quickly be productive with any required changes, updates, or troubleshooting.

Productivity2000 Memory Map:

Comprehensive Help Files

You can browse the actual help files here. These are the same detailed help files available from within the software, with full details about each instruction and all aspects of the software environment.

Here is a sample screen:

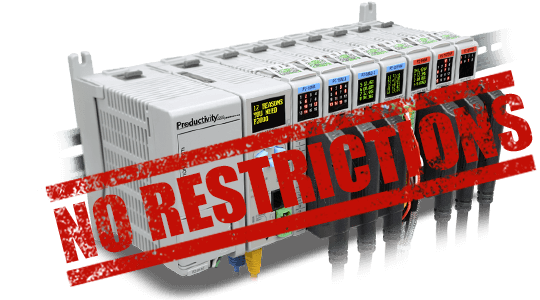

FREE Software Download

That's right, we offer the Productivity Suite programming Software as a free download. It's the full package - no restrictions - no limitations. That's a $495 value - Free! Download it here , or continue exploring it online here.

We want you to see how the Productivity Suite can enhance your productivity. So go ahead, download the software and take a look. From the auto-discovery of your I/O modules and VFDs to the Application Specific instructions , we've put our 20 years of programmable controller software experience and all of your great customer suggestions and feedback into the Productivity Suite. Give it a try, and let us know what you think.

Your success is our success!

As the world around us becomes more and more automated, an understanding of electrical control systems becomes more and more vital. To better serve our customers and the industry we rely on, we offer absolutely free online training to anyone looking to learn PLCs. No purchase necessary! This training covers both basic PLC fundamentals as well as specific training on the Productivity Suite Programming Software. Check out this free training here: www.automationdirect.com/plc-training

"No Problem" programming is programming without restrictions.

The Productivity2000 is a tag name based controller which allows for more freedom and flexibility than fixed-memory controllers.

- Does your application need 2000 timers but only 15 counters? No problem!

- Or maybe it needs 4000 real numbers and only 30 integers? No problem!

What about connectivity? No problem there either, with most Productivity CPUs you can choose to program via the Ethernet port or use the plug and play USB Port. Need to incorporate an HMI/SCADA interface? Problem solved! Easily import your tag database into HMI/SCADA software such as C-more for trouble-free development. Improved documentation, faster troubleshooting, reduced development time, easy setup and an overall better programming experience all at an unbeatable price!

No Arbitrary Limits Either:

The Productivity2000's fast processor and programming environment free you from many arbitrary and fixed limits that many other PLC/PACs impose. With no practical limit on the number of PID loops, timer or counter commands, programmers are able to take full advantage of the power of your Productivity Series controller.

- No limits on PID loops*

- No limits on Counters*

- No limits on Timers*

*Limited only by the available memory in the PLC.

So you can be productive, not limited by your PLC software.

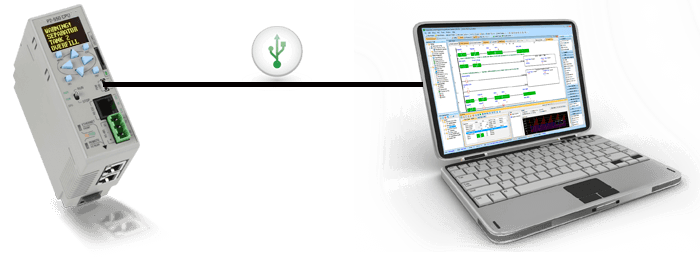

Plug-and-Play Programming

Have you ever felt unproductive while configuring stop bits, parity, or baud rates in order to connect to a programmable controller? The Productivity2000 uses USB programming for true plug-and-play functionality. Plug in your USB cable and move on to the productive activities like configuration and programming.

You can program across Ethernet as well, but we wanted Productivity2000 to have a fast reliable way to get started. When combined with auto-discovery of I/O modules, the USB plug-and-play capability helps you be productive right away.

Take a look at our video "Program-ready in minutes".

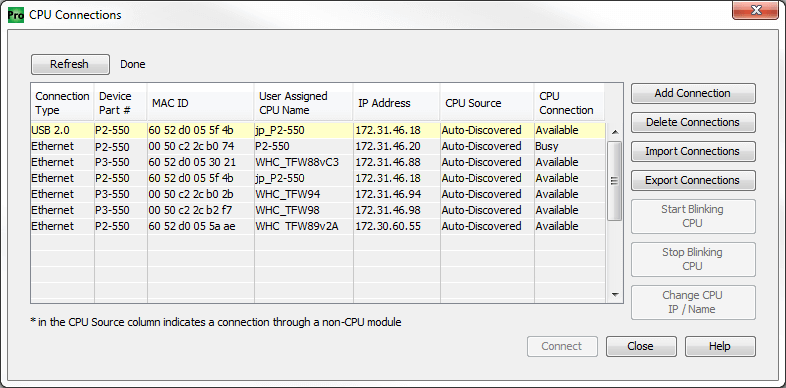

Ethernet Programming

The Productivity Suite programming software supports both USB programming and Ethernet Programming. The PLC Connections dialog box (shown below) allows you to connect to any PLC on your network for programming or data monitoring operations. The PLC Connections dialog even dispays PLCs that are on other subnets, and will allow you to change the IP address and name of those PLCs so that you can connect to and program those as well. The "Blink CPU Display" buttons are a great way to make sure you are connected to the intended PLC, before risking a program transfer.

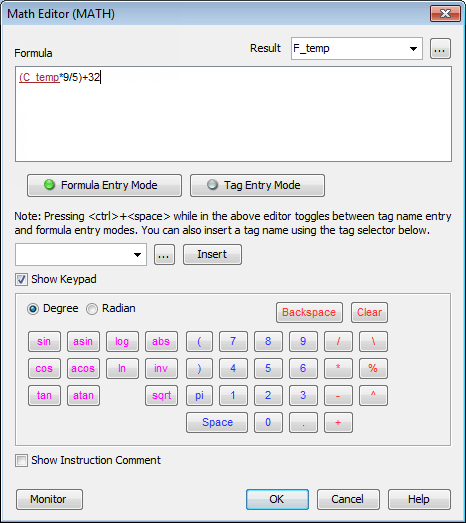

Nimble Math Instructions

The Productivity Suite makes mathematical operations a cinch. Simply type your formula into the formula box area, or use the calculator style keypad to enter equations. Insert tagnames wherever they are needed, and make sure to enter a tagname for the result. You can type the tagnames or use the tagname chooser to look up a specific tag and insert it. How much more productive could this make you?

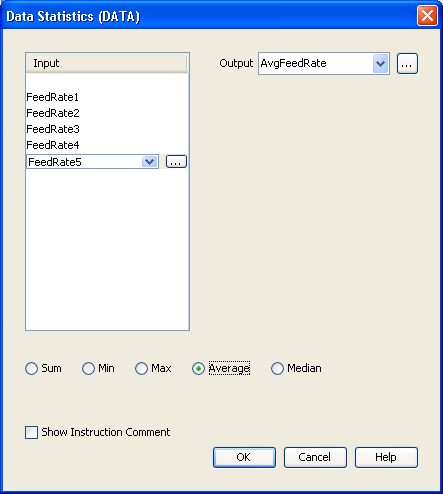

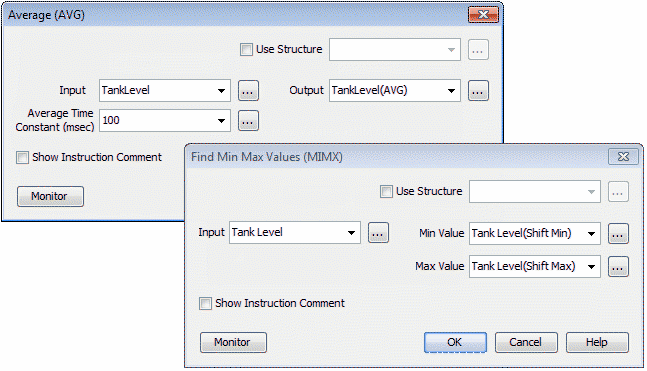

In addition to the Math Instruction, the Productivity Suite offers the Data Statistics instruction shown below for calculating sums, averages, or median values or for determining the Min. or Max. value from a group of tags. Simply type or select your tags from the pulldown list, and enter a tag for the output.

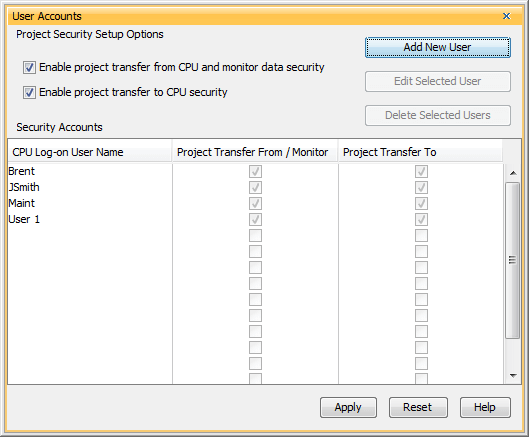

Multi-Level Security Options

Need to secure your Productivity2000? Enable the two security options, and create the desired user accounts. You can allow users to read the project and monitor data only, and/or allow them to transfer projects into the PLC (make changes). Manage the user accounts independently, or quickly turn the security levels on and off globally for all users.

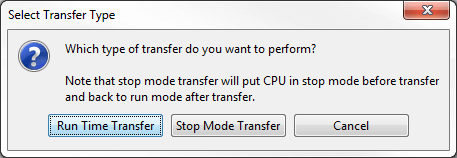

Run-time edits

Commissioning or troubleshooting a system can be less time-consuming if you can make program edits on the fly. Download edits to the CPU without pausing I/O updates or stopping/restarting the program. From melting rubber to making paper, you can keep your process running, avoiding downtime and product waste.

Application Specific Instructions

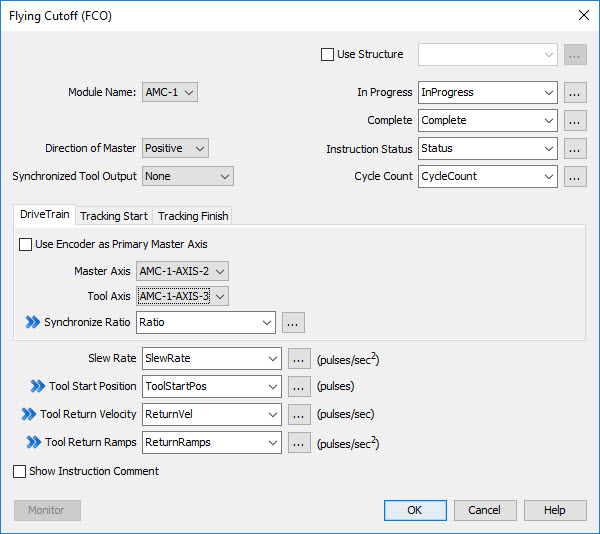

In Productivity Suite there are so many time-saving instructions, even application-specific instructions like Flying Cutoff, and they all have one thing in common - their "fill-in-the-blank" programming method. This method makes it easy to configure tasks that used to require a whole bunch of program code. With Productivity Suite you just fill in the blanks. How productive is that! This style of programming is offered for even the more complex functions - coordinated motion profiles, array functions, communications, PID, the list goes on and on.

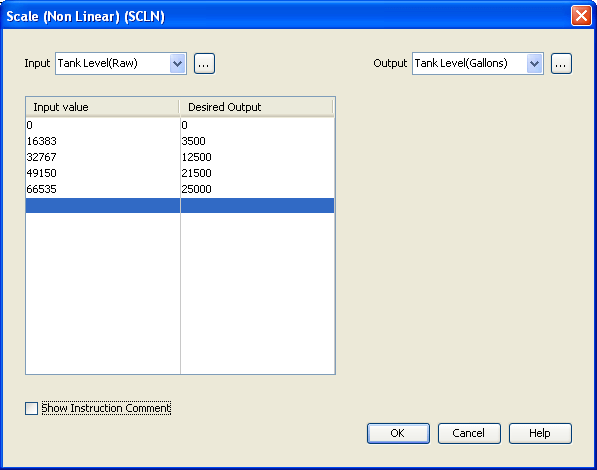

In this non-linear scaling example, the volume of the cylindrical tank needs to be determined based on the measured height of the fluid:

With the SCLN instruction it's a simple matter to enter a few pairs of values, and the Productivity2000 interpolates between the points:

Of course with this particular example additional pairs of values could be used to improve the accuracy of the conversion.

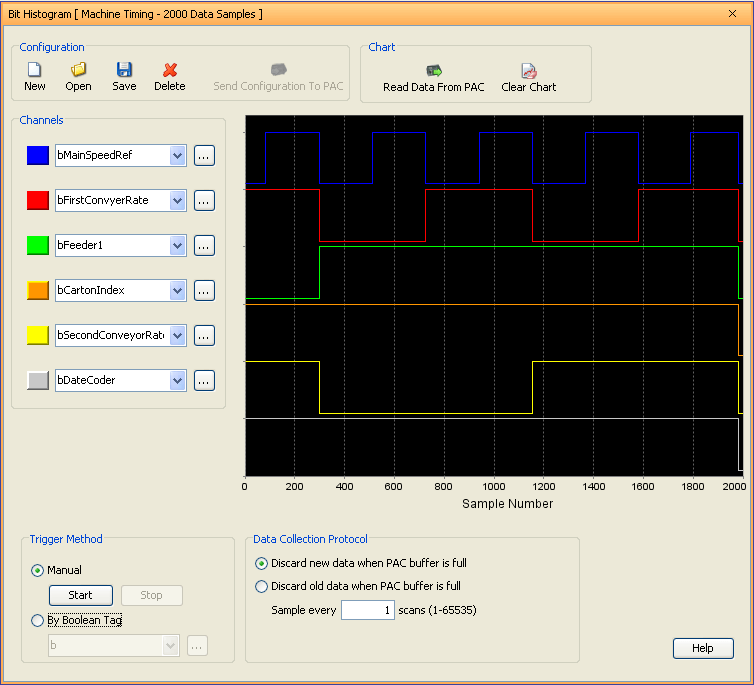

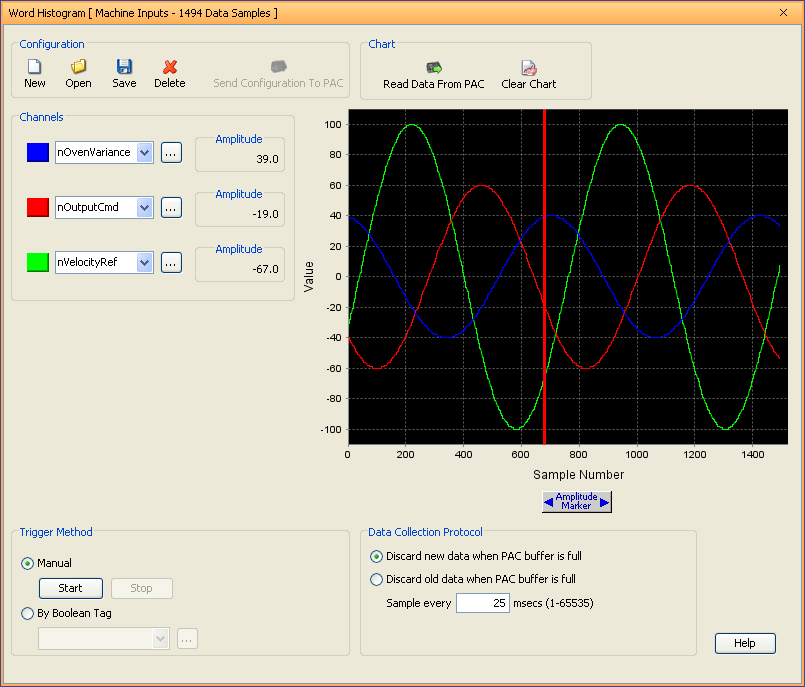

Analyze Tag Data with Bit & Word Histograms

Bit Histograms allow you to clearly see what is happening - and when - at the bit level. Identify race conditions, isolate control issues, and verify proper operation of your machine or process. Trigger the sampling manually, or based on a tag value. Sample as often as once every scan, or at some less frequent period that you select. Save multiple histogram configurations and quickly gather the same data again in the future without going through the setup process.

Word histograms offer similar capabilities for analog tag values.

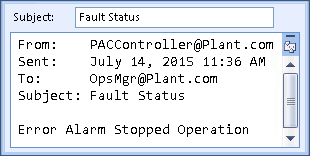

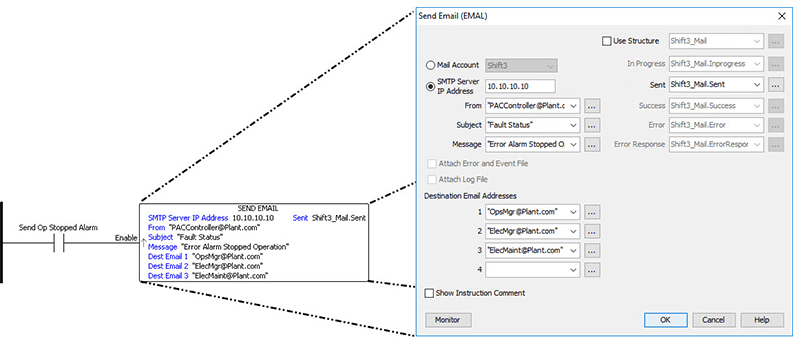

Built-in E-mail Capability

Sending E-mail from the Productivity2000 couldn't be easier. All you need is an SMTP gateway on the same network as your Productivity2000 controller (See notes below.)

Trigger your e-mails based on alarms or other noteworthy events. Enter up to 4 e-mail addresses for each e-mail to be sent. The Subject and Message fields can contain tagname data or descriptive text. Use the Pack String Instruction to combine text and tag data into a single descriptive string tag for the most detailed and informative messages.

Using a TLS Mail Account (configured in the Hardware Configuration) will allow you to send an attachment and/or log files which can be the latest file stored in the USB or Micro SD memory device.

The Send e-mail (EMAL) instruction shown below makes sending e-mail from the Productivity2000 a snap.

Notes: There are e-mail forwarding/server programs that can run on a PC on the same local area network as the Productivity2000. There are also e-mail relay services that are accessable over the Internet that may help.

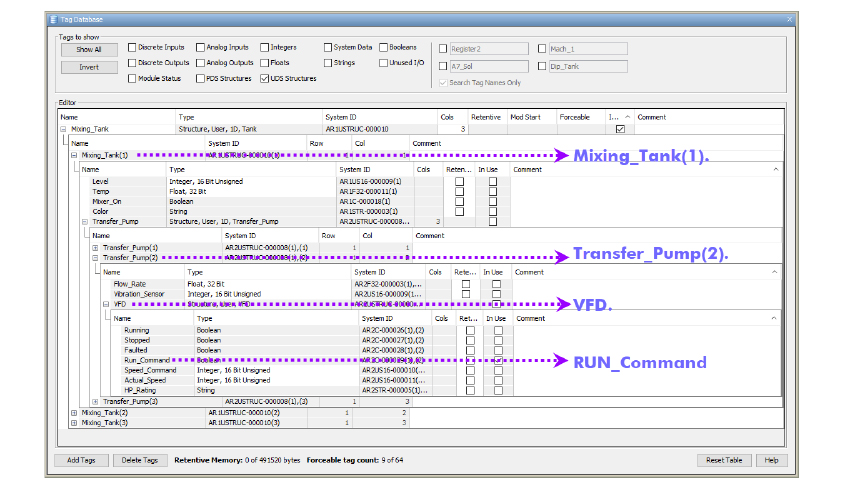

User defined structures

User defined structures (UDS) are a powerful tool that helps speed up program development and improve uniformity of your logic. A UDS is a group of data types (BOOL, FLOAT, INT, pre-defined structures, etc.) which are defined by the user and re-used at will.

Productivity Suite allows you to also create a 1-dimensional array of UDS so that you can programmatically index through your tag variables, such as

Tank1_Mixing_Pump(1).Start or Tank1_Mixing_Pump(2).Flow_Rate.

You can further nest UDS up to four levels deep.

See VFD nested under Transfer Pump (1 level).

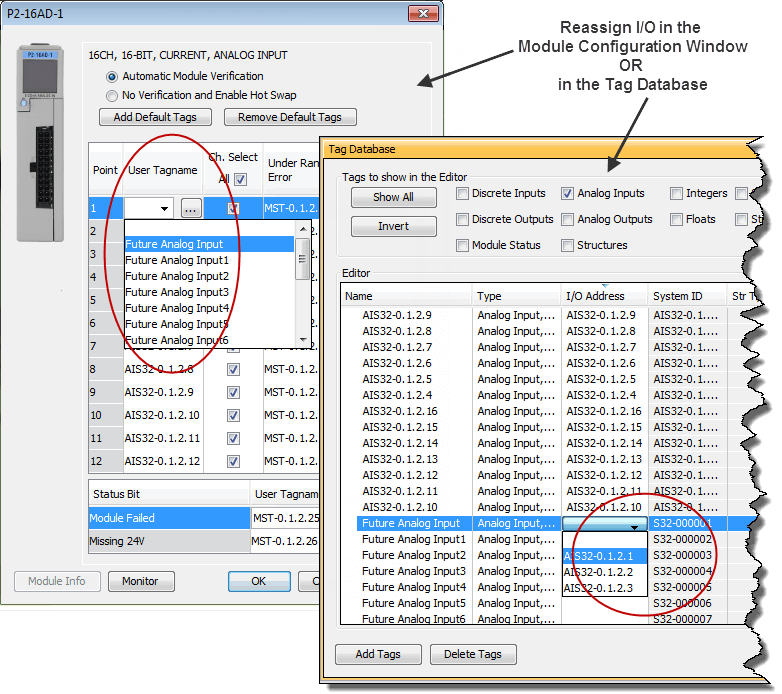

Tag I/O Reassignment

Tag I/O Reassignment allows a user to create tags, at will, without knowing what I/O modules are (or will be) installed in the system. Users can create tags, then later reassign these tags to I/O points at any time (assuming that the modules have been configured in the Hardware Configuration). Tags can be reassigned in the tag database OR in the module configuration window.

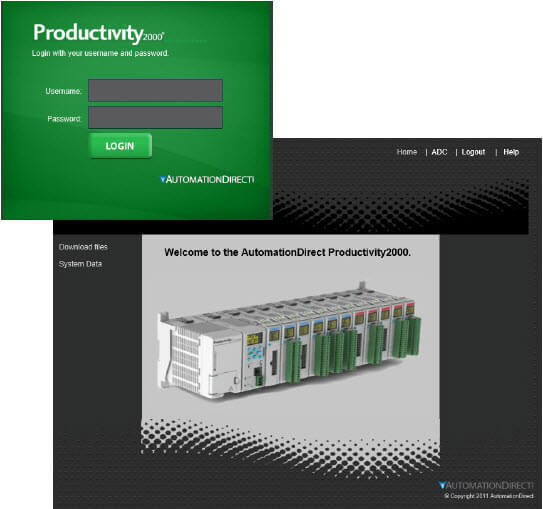

12. Web Server

Access data files and system tags remotely from any web browser, anywhere! The secure password protected login prevents unwanted access and keeps data safe. With the CPU's integrated Web Server you can access Data Logger files stored on an installed flash device (optional) as well as monitor system status via the (read-only) System Tags.

Secure Login:

Set your Username & Password to prevent unwanted access

Main Screen:

Once you have accessed the internal webpages, select the Download files (user-defined data logging files) or the list of System data categories for viewing.

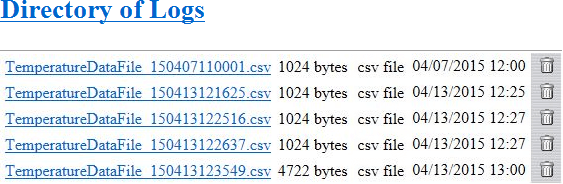

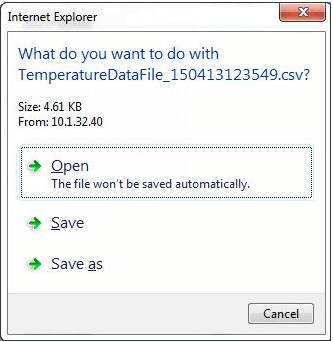

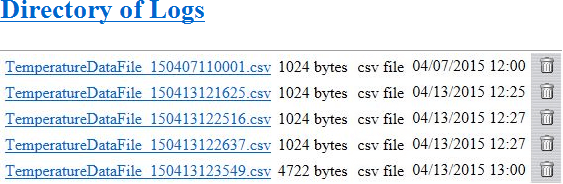

Accessing Data Files:

Data log files are presented in a directory based on the file names and the frequency of archive you select when configuring the Data Logger. From the Web browser you can easily manage these files. You have the options of viewing, saving or deleting the files from the flash device. Also, when you select the "Log System Errors" in the Data Logger, you gain access to the Error log file.

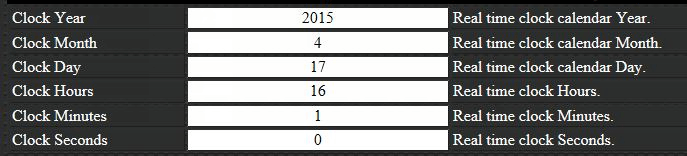

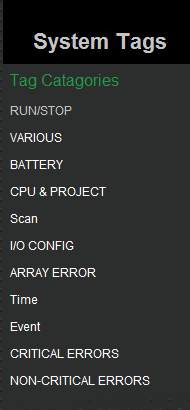

Accessing System Tags:

When you select the System Data option from the Web server main screen you have access to all read only System tags in the CPU. These are divided into the categories shown at right:

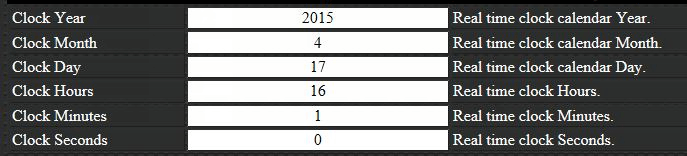

This example below shows the CPU Date & Time tags:

Check out our job openings

Free Online PLC Training

FREE Video Tutorials

FREE e-Newsletter

Automation Notebook

Product Literature

White Papers

News, Product and Training Bulletins

E-Books

Safe &

Secure

Safe &

Secure

We accept VISA, MasterCard, Discover, American Express, PayPal or company purchase orders.

Voted #1 mid-sized employer in Atlanta

Check out our

job openings

Loading...

Loading...