Cookies are not enabled on your browser.

Cookies are not enabled on your browser.Cookies are required for our site. Please enable cookies in your browser preferences to continue.

- Barcode / RFID / Vision

- Bulk Wire & Cable

- Cables (Terminated)

- Circuit Protection / Fuses / Disconnects

- Communications

- Drives & Soft Starters

- Enclosure Thermal Management & Lights

- Enclosures & Racks

- Field I/O

- HMI (Human Machine Interface)

- Hydraulic Components

- Motion Control

- Motor Controls

- Motors

- Pneumatic Components

- Power Products (Electrical)

- Power Transmission (Mechanical)

- Process Control & Measurement

- Programmable Controllers

- Pushbuttons / Switches / Indicators

- Relays / Timers

- Safety

- Sensors / Encoders

- Stacklights

- Structural Frames / Rails

- Tools & Test Equipment

- Valves

- Water (Potable) Components

- Wire & Cable Management

- Wire & Cable Termination

- Retired Products

Configuration Utilities

- PLC Family Selector

- P1000 PLC Systems

- P2000 PLC Systems

- P3000 PLC Systems

- ProductivityCODESYS

- CLICK PLC Systems

- Do-more® BRX PLC Systems

- LS-Electric® XGB PLC Systems

- Productivity®Open Systems

- Datalogic® Safety Light Curtains

- LS-Electric® Servo Systems

- Nitra® Pneumatic Grippers

- Object Detection (Sensors)

- PAL Controller Configurator

- Precision Gearbox Selector

- Protos X® Field I/O

- Pyrometers Selector

- Quadritalia® Modular Enclosures

- Stellar® Soft Starters

- Stepper System Selector

- SureFrame T-slot Extrusion

- SureMotion® XYZ Gantry

- SureServo2® System Selector

- SureStep® Linear Actuators

- Timing Belts & Pulleys

- Werma® Stacklights

- ZIPLinks

On the cutting edge

The gap between plant-floor systems and front-office operations is closing at a rapid pace. Data sharing between logistics, accounting, maintenance, production, and other departments provides "big-picture" oversight, which results in better planning, reduced waste, and higher efficiency.

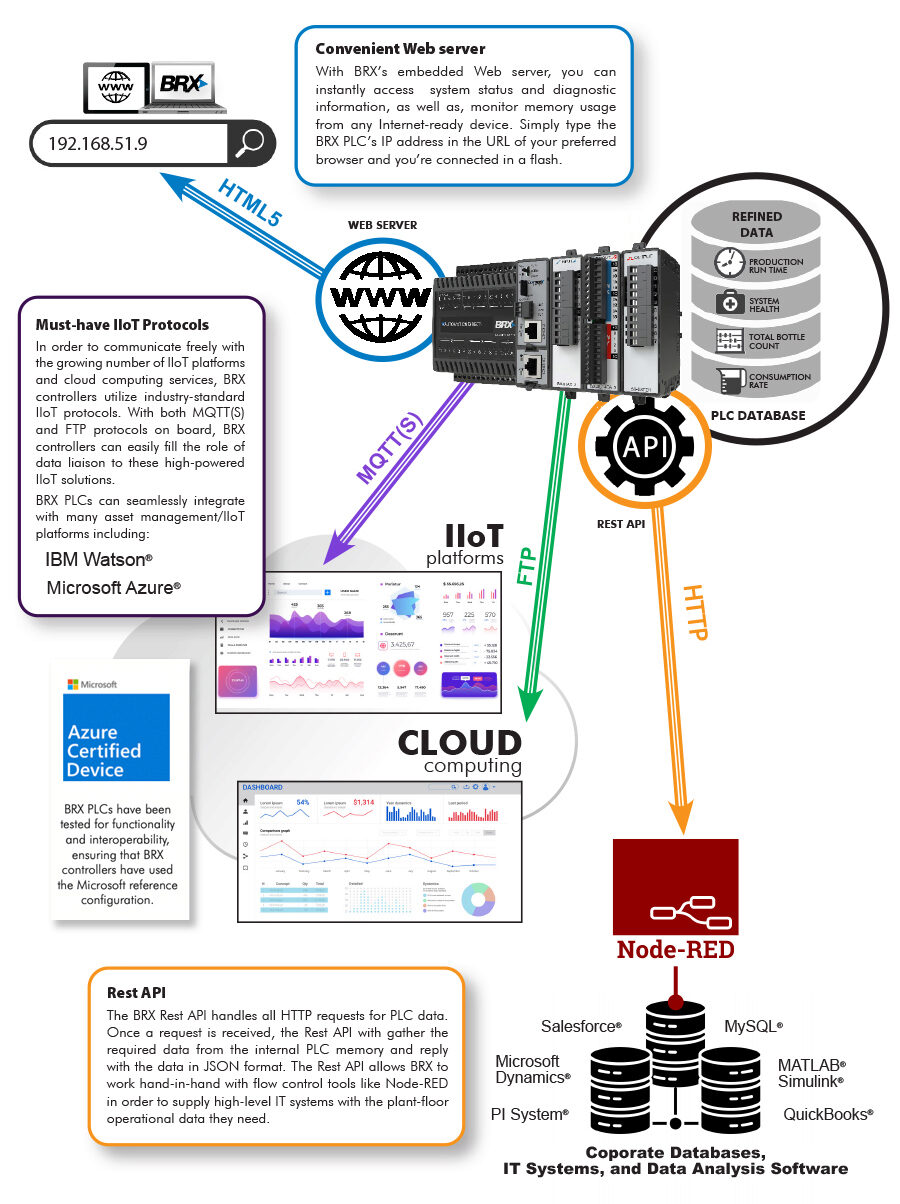

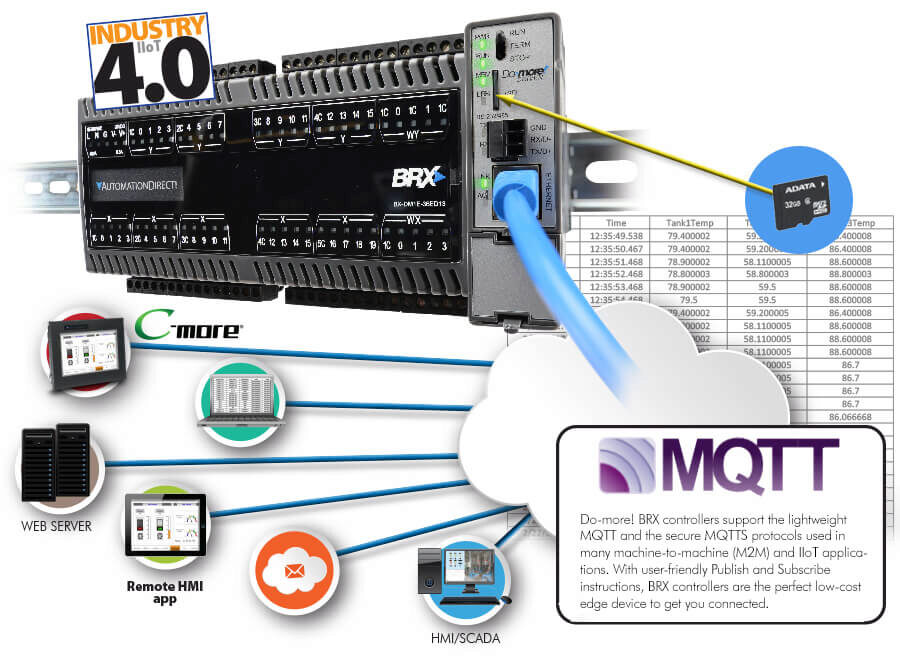

Modern-day PLCs, like the Do-more! BRX, have adapted to the demand for higher-level data exchange. BRX has advanced data logging and communication features, including an embedded Rest API and native MQTT(S) protocols, that allow it to easily take on the role of an edge device - gathering, refining and delivering control data to upstream IT collection and analysis systems.

Your low-cost link to the Industrial Internet of Things (IIoT)

Discover new opportunities

Data collection has become an important part of any control system. With quality data, system performance can be improved and inefficiencies eliminated. Ethernet communication and the Industrial Internet of Things (IIoT) have opened up industrial data collection to new frontiers with better access and analysis. With the integrated data logging capability and robust communication available with the Do-more! BRX platform, you can not only collect the process/machine data you need and store it locally, but also deliver real-time OT data to upstream IT systems for detailed analysis.

Each BRX CPU includes 1MB of internal RAM data storage with an optional 32GB of external microSD data storage.

Log the values you want, when you want (by event or by time interval) without purchasing anything extra, or use the optional Ethernet communication to send data to external systems for storage and analysis. Now you too can discover new opportunities, which data can deliver, with low-cost BRX PLCs.

Here is just a sample of what data can do for you:

- Process improvements

- Diagnostics and predictive maintenance

- Quality control

- Energy efficiency enhancements

- Production forecasting

- Environmental compliance

- Expense tracking

- Research and development

Built for the Information Age

The World Wide Web is full of valuable information that is instantly available for anyone, anytime. Why not put that information to work for you? With BRX PLCs you can! BRX PLCs allow you to communicate with web servers using HTTP and JSON instructions. The data that BRX can pull from these servers can be easily incorporated into your application's control strategy:

- Use the current forecast from your favorite weather site to control the watering cycle for your crops

-Take the sun's azimuth and altitude from a sun tracker site and use it to determine solar collector positioning

-Build you own custom webpage to interface with your remote PLC

With BRX PLCs, the control possibilities really are endless!

Better Communication Through Innovation

Built-in Communication Ports

The Do-more! BRX platform includes built-in communications options to meet the demands of modern-day industrial networks. With a software-selectable RS-232 or RS-485 serial port on every MPU and the option of a built-in 10/100 Mbps Ethernet port, the BRX family can easily integrate into existing older networks as well as newer modern networks.

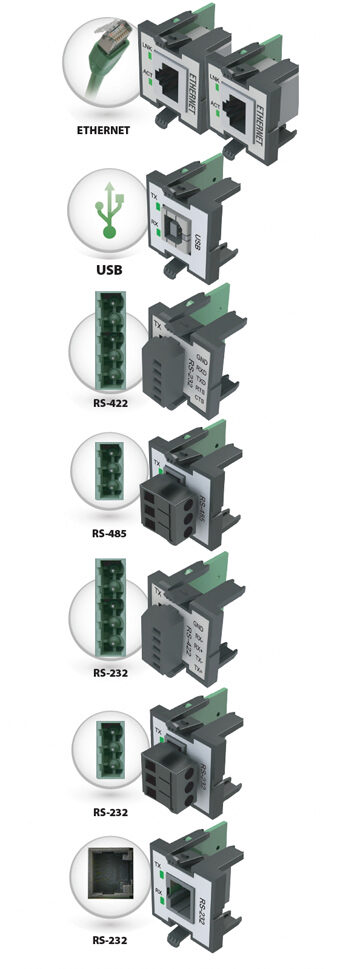

POMs (Pluggable Option Modules)

Communication that adapts to your needs...and your budget

PLC communication is an ever-changing landscape with Ethernet and USB being the latest additions. Modern PLCs need to provide the ports and

protocols required to easily navigate the communication choices available. But how do you accommodate PLC communication that keeps evolving?

The BRX platform has a practical solution, the CPU Pluggable Option Module or POM.

Besides the built-in RS232/485 serial port and the built-in Ethernet port (on all BX-DM1E models), all of the BRX CPUs have an

optional slot for an additional user-selected POM. These hot-swappable POMs are currently available with RS232 (with and without flow

control), RS422, RS485, USB 2.0 and Ethernet options. Add the extra communication port you need now and change it if your needs change.

Serial now but USB later, or USB now and Ethernet later - the choice is yours, now and in the future.

Don't want to pay for

communication ports you won't use? With the Do-more! BRX PLC platform and the innovative POMs, you won't. In addition to the built-in ports,

the POMs allow you to configure your CPU for the exact communications you need when you need it. Need just one extra serial port? How about a

dedicated Ethernet programming or HMI port? Or maybe you need a single USB connection? With BRX PLCs you get more communication options for

better savings and overall satisfaction.

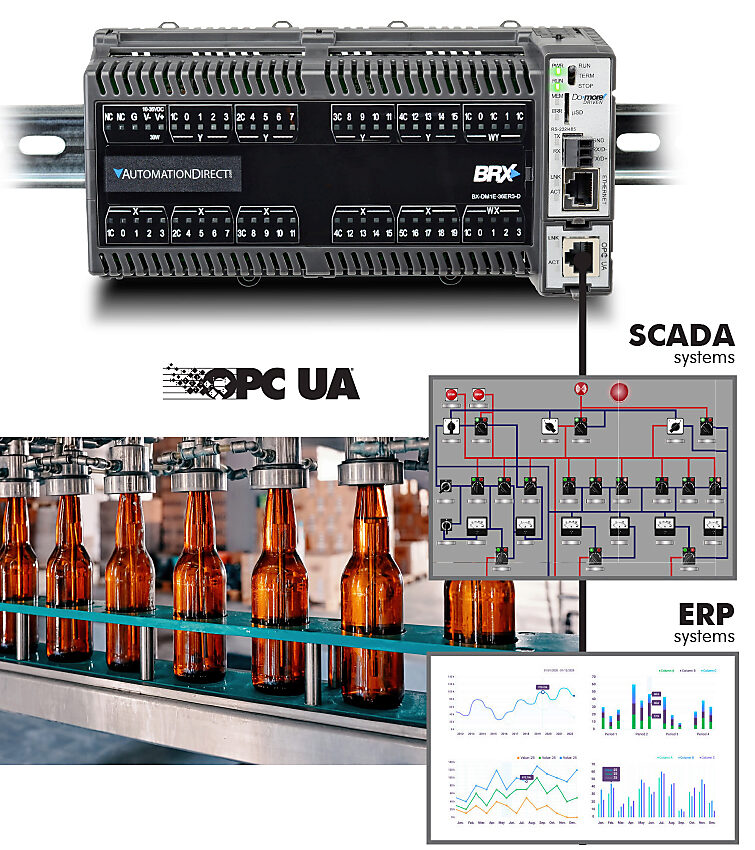

OPC UA (Open Platform Communications Unified Architecture) is a mature, widely adopted industrial communication protocol that enables seamless, secure, and standardized data exchange between systems and devices from multiple manufacturers. Its platform-independent framework supports rich, hierarchical data models and real-time communication, making it ideal for complex industrial automation environments. Key benefits include:

- Scalability: handles large volumes of data across a wide variety of applications with ease

- Robust security: built-in authentication, authorization, and encryption ensure safe data transfer

- Interoperability: simplifies integration of mixed vendor systems for reliable multi-vendor cooperation

- Real-time efficiency: facilitates timely data exchange to optimize processes and improve system responsiveness

The BX-P-OPCUA POM expands the capabilities of the BRX CPU by providing direct integration into OPC UA networks. By removing the need for an external OPC UA server, it reduces system complexity and cost. This compact yet powerful module streamlines connectivity, enhances data exchange, and delivers dependable performance, making it an ideal choice for modern industrial automation. Discover how the BX-P-OPCUA POM can simplify your architecture and boost productivity.

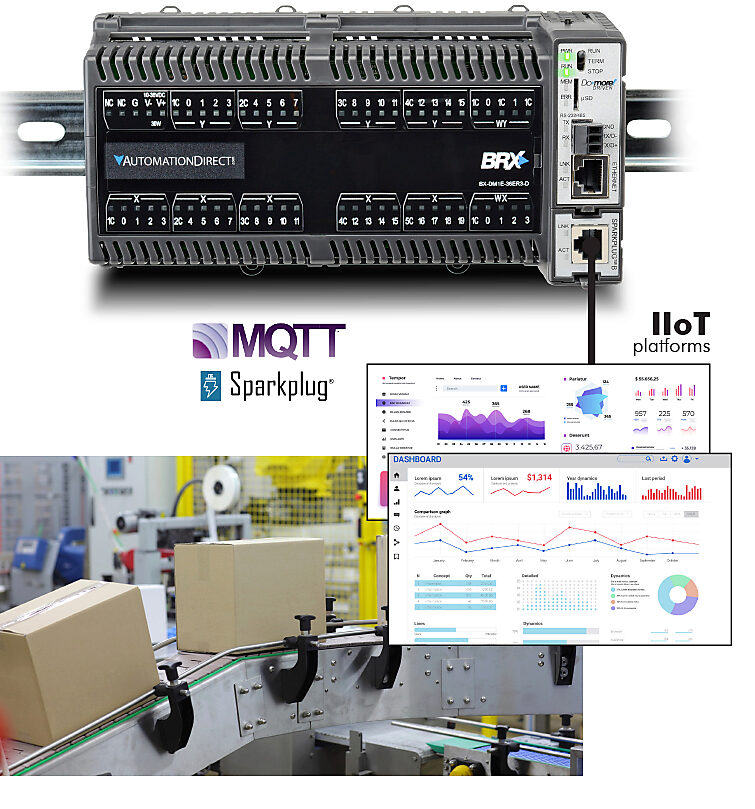

Sparkplug B takes the foundational benefits of MQTT and enhances them with the specific requirements of industrial automation and IIoT, making it a powerful and widely adopted specification for modern industrial communication. Adding the BX-P-SPARK POM to your BRX PLC offers several benefits, including:

- Interoperability: Sparkplug B offers a unified approach for device manufacturers and software providers to share data, enabling seamless integration in diverse industrial IoT (IIoT) ecosystems. This helps avoid data silos and promotes a "plug-and-play" environment.

- Efficiency: Its lightweight payload makes messages compact, reducing bandwidth usage, which is crucial for resource-constrained environments or networks with limited bandwidth.

- State Awareness: It gathers real-time knowledge of device connectivity and status. This is critical for industrial operations where knowing if a sensor or machine is online is paramount for monitoring and control.

- Data Context and Richness: Sparkplug B mandates the inclusion of timestamps, data types, and metadata with each metric. This ensures that the data is not just a raw value but also carries important context, making it more meaningful for analysis and decision-making.

- Scalability: The publish/subscribe model of MQTT, combined with Sparkplug B's structured approach, allows for highly scalable IIoT deployments, as devices and applications are decoupled.

- Simplified Integration: With a standardized topic and payload, integrating new devices or applications into an existing Sparkplug B system becomes much simpler, reducing development and configuration efforts.

- Enhanced Security: Leveraging MQTT's security features (like TLS/SSL for encryption and authentication mechanisms), Sparkplug B ensures data integrity and confidentiality during transmission.

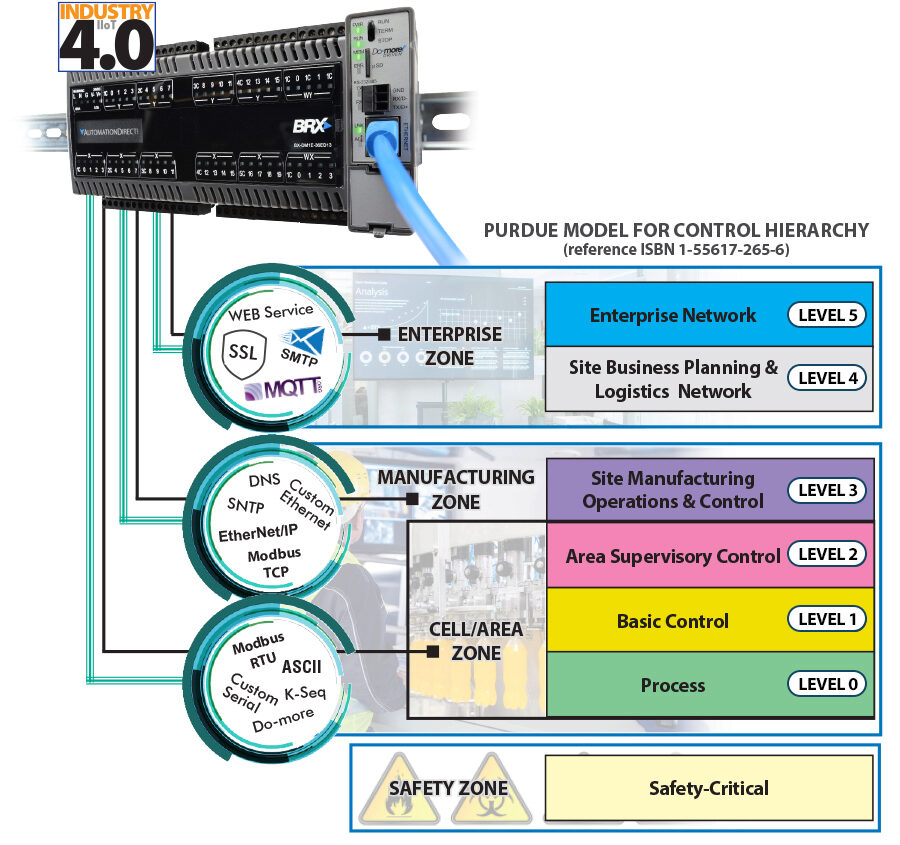

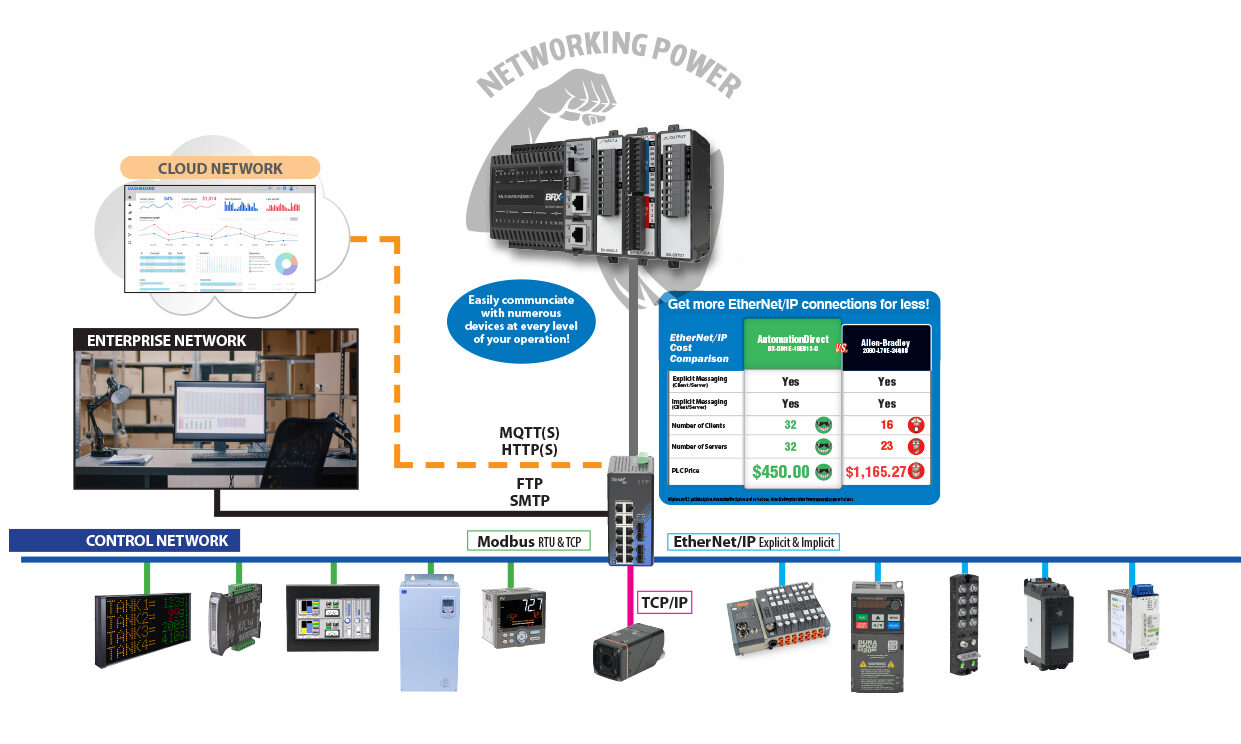

Take the work out of Network

In modern industrial communication there are numerous protocols that dominate the landscape. EtherNet/IP and Modbus are two of the prominent protocols used by many control device manufactures. BRX PLCs support a wide array of industrial protocols including EtherNet/IP, Modbus TCP/RTU, and secure, DMZ-safe protocols such as MQTT, MQTTS, Sparkplug B, OPC UA, HTTP, and HTTPS.

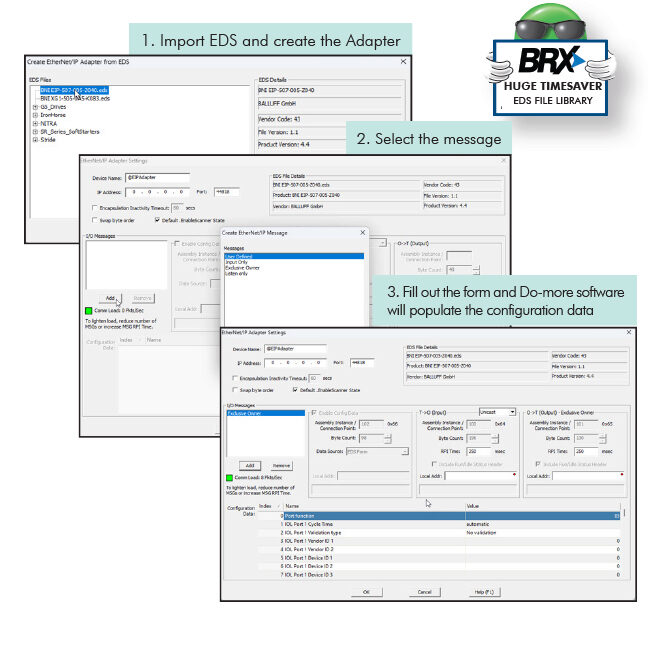

But when it comes to EtherNet/IP, the Do-more Designer software provides built-in features to make device configuration a cinch. First, Do-more BRX PLCs can be configured as scanners or adapters and support both Explicit and Implicit messaging. An embedded EDS file library offers an easy way to upload, store, and manage your EDS files (EDS files are simply ASCII files that describe how a device can be used on an EtherNet/IP network). These files are organized in a simple-to-use drop-down menu with the ability to select multiple connection options from each EDS file. New devices can be easily added to the library and AutomationDirect.com EtherNet/IP EDS files are preloaded in the library for convenience.

EtherNet/IP that's easy as 1, 2, 3

With the "other guys" PLCs, configuring EtherNet/IP devices can be a real pain. Searching device manuals to find the correct configuration data and entering each value in the PLC project line by line is tedious and a waste of time. With Do-more Designer, you can save valuable time and let the software populate the configuration data for you.

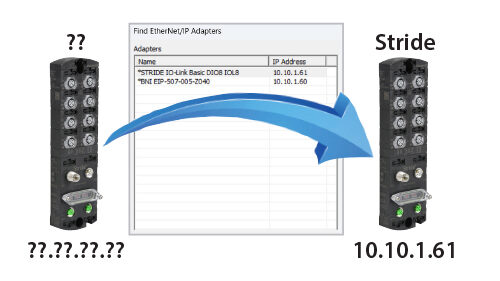

If that's not easy enough, Do-more Designer can also auto-discover existing EtherNet/IP adapters for in-an-instant device additions to your control network.

Check out our job openings

Free Online PLC Training

FREE Video Tutorials

FREE e-Newsletter

Automation Notebook

Product Literature

White Papers

News, Product and Training Bulletins

E-Books

Safe &

Secure

Safe &

Secure

We accept VISA, MasterCard, Discover, American Express, PayPal or company purchase orders.

Voted #1 mid-sized employer in Atlanta

Check out our

job openings

Loading...

Loading...