Cookies are not enabled on your browser.

Cookies are not enabled on your browser.Cookies are required for our site. Please enable cookies in your browser preferences to continue.

- Barcode / RFID / Vision

- Bulk Wire & Cable

- Cables (Terminated)

- Circuit Protection / Fuses / Disconnects

- Communications

- Drives & Soft Starters

- Enclosure Thermal Management & Lights

- Enclosures & Racks

- Field I/O

- HMI (Human Machine Interface)

- Hydraulic Components

- Motion Control

- Motor Controls

- Motors

- Pneumatic Components

- Power Products (Electrical)

- Power Transmission (Mechanical)

- Process Control & Measurement

- Programmable Controllers

- Pushbuttons / Switches / Indicators

- Relays / Timers

- Safety

- Sensors / Encoders

- Stacklights

- Structural Frames / Rails

- Tools & Test Equipment

- Valves

- Water (Potable) Components

- Wire & Cable Management

- Wire & Cable Termination

- Retired Products

Configuration Utilities

- PLC Family Selector

- P1000 PLC Systems

- P2000 PLC Systems

- P3000 PLC Systems

- ProductivityCODESYS

- CLICK PLC Systems

- Do-more® BRX PLC Systems

- LS-Electric® XGB PLC Systems

- Productivity®Open Systems

- Datalogic® Safety Light Curtains

- LS-Electric® Servo Systems

- Nitra® Pneumatic Grippers

- Object Detection (Sensors)

- PAL Controller Configurator

- Precision Gearbox Selector

- Protos X® Field I/O

- Pyrometers Selector

- Quadritalia® Modular Enclosures

- Stellar® Soft Starters

- Stepper System Selector

- SureFrame T-slot Extrusion

- SureMotion® XYZ Gantry

- SureServo2® System Selector

- SureStep® Linear Actuators

- Timing Belts & Pulleys

- Werma® Stacklights

- ZIPLinks

DURApulse GS4 AC Drives

Full featured, Full size... Durapulse Drives up to 300HP!

Starting at $609.00

Starting at only $609.00, GS4 AC inverters are loaded with features!

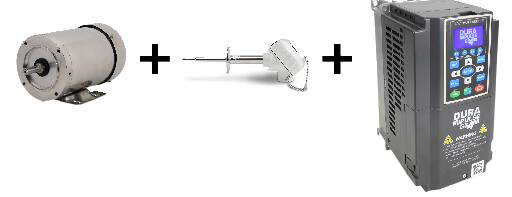

Variable frequency drives (VFD) enable speed control for three-phase AC motors such as those in conveyors, fans, pumps and material handling. DURApulse GS4 series AC inverters in sizes up to 300hp offer V/Hz or sensorless vector control, Safe Torque Off (STO), 100kA Short Circuit Current Rating (SCCR), a built-in logic controller and a host of other advanced features.

- 1-100 hp, 230VAC (single/three-phase input)

- 1-300 hp, 460VAC

Features

- V/Hz control or sensorless vector in all 8 frames sizes

- All 230V drives (up to the 100 hp model) have single-phase input capability.

- Dual Rating Design - CT/VT Ratings (Light & Heavy Duty)

- Flexible Carrier Frequency to 15khz and Output Frequency to 600Hz

- STO - Safe Torque Off (TUV Certified)

- Built-in PLC to support up to 10k steps

- 100kA Short Circuit Current Rating

- Free Downloadable Software for Drive Configuration and for PLC Programming

- Field-upgradable Firmware via USB port (Drive, Keypad, & Communication Option Cards)

- Hot-Pluggable LCD Text-Based Keypad (IP20/NEMA1) can be remotely mounted

- Embedded Quick-Start Menus

- Local/Remote control mode selection from the Keypad or digital/comm input with Hand/Off/Auto Control

- Display Units of Measure of your choice (GPM, FPM, etc.)

- Momentary Power Loss Restarts

- Built-In DC Choke (some models)

- Flange-Mount Capability for frame sizes A to F (1 to 215 hp)

- Conduit Box(s) for NEMA 1 (Frame sizes D0 to G)

- Expanded I/O capability - 110V Inputs, Relay Outputs, combo DC I/O card

- Analog I/O - Configurable 3 Inputs and 2 Outputs

- Auto Speed Search capability

- Multi-Motor Control

- Dynamic Braking - Built in up to Frame C, Optional Dynamic Braking units for Frame D+ and comprehensive offering of resistors

- PID Controller - Including Sleep and Wake Password Protection

- RTD and/or PTC Input Motor Protection

- Parameter Organization similar to GS3 - GS3 Operational (External User PLC) control will work with minimal changes required.

- Calendar function allows a user to program the PLC with ON/OFF control in chronological order, daylight savings time, etc.

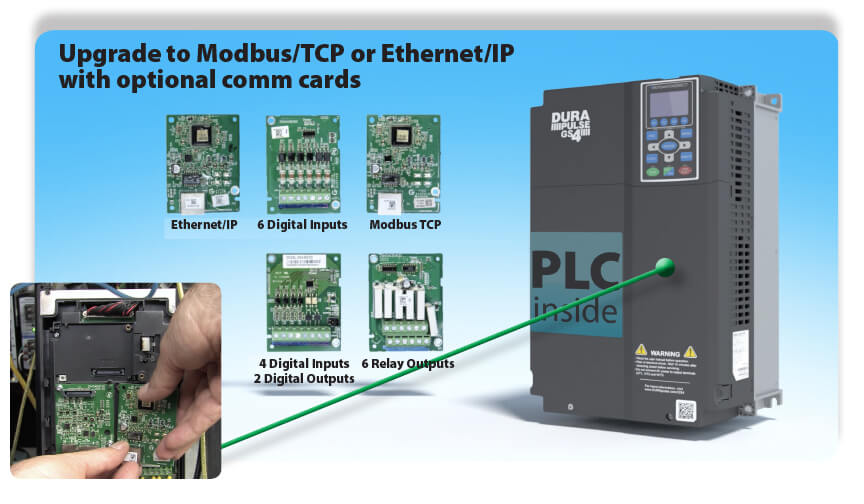

- High speed communication interfaces with MODBUS RTU and BACnet protocols built in, with optional communication cards: MODBUS TCP, EtherNet/IP

- Long-life design and self diagnosis for key components

- Modularized design eases maintenance and expansion, including quick replacement of fans

- Circuit boards have conformal coating for improved environmental tolerance

- Excellent heat-sink design; able to operate at 50°C ambient temperature

- Fire Mode - Run fire mode during emergencies to have uninterrupted smoke removal and system pressure

- Multi-pump control: fixed quantity, fixed displacement, and fixed time-circulating control; able to control up to 8 pumps at the same time (Optional multi-control relay output card is required.)

- Two-year warranty

- CE, TUV, UL, cUL

A built-in PLC and expanded I/O capabilities

PLC inside

A fully functional PLC is built in to the GS4 drive. Capable of up to 10k steps, it's perfect for drive related logic requirements. Control the drive and I/O with standard ladder logic (and our FREE downloadable PLC software: GS-Logic). Advanced PLC features include: 32-bit math, Gray Code, drive frequency control, read/write drive parameters, real-time clock/calendar with support for daylight savings time and full drive PID control. And it's all on-board!

Watch Video - Introducing the GS4 Variable Frequency Drive

You have I/O choices

Perfect for drive related and PLC operations, the built-in I/O includes eight DC digital inputs, two DC digital outputs (up to 48V), 2 form-C relay outputs, as well as five analog channels (3 inputs and 2 outputs) configurable for either voltage, current or potentiometer (input). The expansion I/O slot will accept any one of three I/O option cards: the combo DC discrete card with four 24VDC input (sinking or sourcing) and two 24VDC outputs, the six-point 110VAC input card, or the six-relay output (250VAC/30VDC) card.

Watch Video - How to Install the Optional Comm Cards

Watch Video - How to update the optional Comm Card Firmware

High-speed communication interfaces

GS4 drives support both Modbus RTU/ASCII and BACnet (serial) protocols out-of-the-box. Modbus RTU is ubiquitous on the factory floor - all PLCs and most other equipment are compatible. Similarly, BACnet is the de facto standard for the HVAC and building automation worlds. The GS4 drives also accept an optional Ethernet card; choose from the Modbus TCP option or the EtherNet/IP version. These economically priced option cards put your GS4 drive on a fast network at a low cost. You'll be amazed at how easily you can setup the drive to communicate with any of our PLCs (especially the newer Do-more and Productivity Series models).

Be safe with DURApulse GS4

Safe Torque Off

The Safe Torque Off (STO) function is a basic drive-integrated safety feature. Use this input signal to ensure that no torque-generating energy can flow to the motor. This function is often used in emergency stop situations and/or to prevent unintentional motor starting.

Watch Video - STO (Safe Torque Off) on the GS4

100kA SCCR rating

A 100kA Short Circuit Current Rating (SCCR) is required for personnel safety in many factory environments and to meet a host of regulatory requirements including:

- NEC Article 409

- UL508A

- NFPA70E

SCCR is defined as the maximum short circuit current a component or assembly can safely withstand when protected by a specific overcurrent protective device, or for a specified time interval. The use of high-speed class J or class T fuses on the incoming power is required for these installations.

50°C rating

The excellent heatsink design of the GS4 series provides a 50°C rating, allowing the GS4 to operate in harsh ambient conditions (that's 122°F!). GS1, GS2 and GS3 models are rated for 40°C, but can require additional cooling for the enclosure. Furthermore, all the GS4 drives up to 215 HP can be "flange mounted", a through-mounting method that puts the drive's heatsinks on the outside of the enclosure. This allows the use of a smaller enclosure, or reduces the need to cool the enclosure, or both!

Fire mode

Run Fire mode during emergencies for uninterrupted smoke removal and system pressure. Sometimes called "run until destruction" mode, this feature should be used as a measure of last resort; it can be useful, even life-saving in certain situations (keeping a stairwell clear of smoke, for instance). The drive will ignore all alarm inputs, and reset immediately on any trips. Use with caution, especially during any testing that is required.

DURApulse GS4 AC drives are in control

Circulative control mode - multi-motor control

The GS4 drives offer five different control modes for circulation pump control. The drive can control up to 8 motors in a cyclic or cascading fashion by using a combination of VFD control and across-the-line control. Relay outputs on the drive operate contactors that allow the VFD to control one or more motors, while additional relay outputs provide across-the-line control of other motors via separate contactors. These modes can be used to balance usage of multiple pump motors, or to provide scalability and efficiency (with vastly differing pumping volumes) with an array of smaller motors.

PID Control - including sleep and wake

The GS4 series drives support full PID control to automatically apply accurate and responsive corrections to a control function with external influences. Proportional, Integral, Derivative (PID) control is a mainstay in industrial control, bringing complex processes up to speed with little or no overshoot, or controlling pressure, force, feed rate, flow rate, position, etc. The Sleep Mode function is actuated when the frequency of the output command or the feedback signal falls below the Sleep Reference point for a specified period of time. When asleep, the drive output is off and it simply monitors Wake-up Reference point. A separate Wake-up Delay Time can be used to delay the Wake-Up routine.

Designed for the future (and backward compatible)

Field upgradeable firmware

Now you can take advantage of new features and functional enhancements even long after you've purchased your VFD. All GS4 drives have the built-in "3-in-1 Firmware Upgrade Module" that allows you to upgrade not only the drive, but also the firmware in the intelligent keypad, and even the optional Ethernet/IP or Modbus TCP cards (if present in your system). Just connect your USB cable to the upgrade module and download the latest firmware; we've even got detailed "Tech Tip" videos that walk you through the entire process!

Rugged dependable design

GS4 drives are designed for long life and maintainability, with self diagnosis for key components. Their modular design makes expansion a breeze and helps ease maintenance (quick replacement of fans, for example). The internal circuit boards all have conformal coating to protect against moisture, dust, chemicals, and temperature extremes.

Already familiar with our GS3 drive?

The GS4 parameter organization is very similar to GS3 - If you have worked with a GS3 drive in the past, you will find most of the parameter settings in the same locations in the GS4. Better yet, if you currently have a PLC connected to a GS3, switching to a GS4 will be very easy, with minimal changes required to your PLC program. Of course, you may wish to make some changes to take advantage of all the great new features!

Clock/calendar with support for daylight savings time

The GS4 drives have a real-time clock/calendar that allows the user to program the PLC (and by extension, to control the drive) with ON/OFF control in chronological order, for certain times of day, days of the week, seasonal changes, etc. And it includes full support for daylight savings time.

Momentary power loss restart

After many power loss or brown out situations, the entire machine or process may need to go through a prescribed start-up process, but there are times when having a VFD come back online automatically and ASAP is advantageous. Enable this function and the GS4 drive will automatically restart and use "speed search" to catch the motor on the fly and continue running. The GS4 drive can also be set to automatically restart after a fault (with a limit on the number of fault restarts allowed with a given time frame).

Dual rating design - CT/VT ratings (light & heavy duty)

All the GS4 drives are rated for both Variable Torque (VT) and Constant Torque (CT) applications, making the selection process easier. VT (light duty) ratings allow up to 120% of current, and CT (heavy duty) allow up to 150% of current for brief periods. Be sure to set these limits carefully to avoid motor damage. There are certain situations in which the GS4 drives may need to be de-rated, at altitude or when using single phase line input, to name a few. See the pages on drive selection for all the derating details.

Flexible carrier frequency to 15khz

The GS4 drives have an adjustable carrier frequency, the rate at which output transistors are gated or switched on and off, from 2 to 15 kHz. Higher carrier frequencies provide better efficiency (lower harmonic losses) in the motor and lower audible noise from the motor. Lower carrier frequencies offer better efficiency in the drive, lower EMI (electrical noise), and reduced reflective wave peak voltage (reflected wave peak voltages can damage motor insulation).

As a general rule, the carrier frequency should be set as low as possible without creating unacceptable audible noise in the motor. Smaller systems can have higher carrier frequencies, but larger drives (>20 or 30hp) should not have carrier frequencies set higher than 6kHz. Heavy duty applications typically run around 2 to 4kHz.

GS4 drives even have the optional ability to automatically change the carrier frequency based on the load (if the drive experiences a more demanding load, it will reduce the carrier frequency until the overload is gone).

Built-in dynamic braking (models below 40hp)

When a variable frequency drive decelerates an AC motor, especially one with a large inertial load attached, the process is known as dynamic braking. While all GS4 Drives are capable of dynamic braking, the smaller sized drives (those below 40 hp) have this capability built in, while the larger drives (above 40hp) require an optional dynamic braking unit. A thermal overload and external braking resistors are required to dissipate the energy safely. A comprehensive line of braking units, thermal overloads, and braking resistors is available; check out our video on Dynamic Braking for all the details.

Watch Video - Dynamic Braking on the GS4

Built-in DC choke (models above 40hp)

Also known as "catch on the fly", this control technique allows the GS4 drive to take control of a motor that is already spinning. In some applications, such as fan control where the fan blade is located in a moving air stream, it isn't always practical or desired to stop the motor prior to bringing it under VFD control. The GS4 drives can send small current signals to the motor to detect the motor's speed, and then engage the motor in full V/Hz or sensorless vector mode within a few seconds. Very advantageous in certain circumstances!

Protect your motor from overheating

Wire a standard temperature sensor (such as an RTD) from your motor into the GS4 drive and protect that motor from overheating. It's a UL requirement in some applications, and a darn good idea ALL of the time. PTC or Positive Temperature Coefficient sensors rely on the electrical properties of certain metals whose resistance increases with temperature. The most common are RTDs (Resistance Temperature Detectors), but thermistors may also be used.

Keypad Features

Intelligent keypad (can mount remotely)

The LCD keypad on GS4 drives is text-based with full English parameter names and descriptions (no mnemonic codes to puzzle over). Configure and store up to 4 complete sets of drive param- eters for backup and recovery operations. It can be remotely mounted with a simple bezel kit and a standard Ethernet patch cable, so you can mount the keypad on the outside of the drive enclosure, near the motor, or the driven machinery. Beyond initial drive setup, the keypad can be used for run/stop control of the motor, or as a scalable speed or frequency display. The keypad has a NEMA 1 rating, and provides ingress protection to IP20.

Watch Video - How to Update the GS4 Keypad Firmware

Display units of measure of your choice (GPM, FPM, etc.)

Configure the keypad to scale and display relevant units for your application. Configure Gallons Per Minute (GPM) of flow for a pumping application, or Feet Per Minute (FPM) for conveyor or material speed, or any other units you desire. Just configure the scaling factor and the units you wish to be displayed.

Embedded Quick-Start menus

The Quick Start menu has the most common motor parameters listed together, so you can get your motor running quickly. Just reference your motor nameplate for a few critical values, and enter them into the drive, and get started FAST! See Chapter 3 of the manual for an overview of keypad operation and our comprehensive quick-start guide (that ships with each drive), or check out our quick-start video to see just how easy it can be.

Watch Video - How to quickly configure the GS4

Mounting and Cooling

Flange mounting

All GS4 drives up to 215 HP can be "flange mounted", a through- mounting technique that puts the drive's heatsinks on the outside of the enclosure. This allows the use of a smaller enclosure, or reduces the need to cool the enclosure, or both! The smaller A through C frame drives have optional flange mount kits, while the D through F frame models come with the flanges already attached. The largest G frame drive isn't normally mounted in an enclosure, so it doesn't have provisions for flange mounting.

Watch Video - Flange Mounting on the GS4

Conduit boxes

Conduit boxes allow larger GS4 drives to be mounted without an enclosure in many applications, saving considerable cost and installation time. The three smallest frame sizes (A-C) have conduit boxes built in, with conduit holes in the bottom of the drive. GS4 drives with conduit boxes are rated for IP20, UL Type 1, and NEMA 1, which generally means that they protect against intrusion by objects and personnel. They aren't protected against dust, water, oil, etc. without an enclosure, so take neccesary precautions if a higher degree of protection is required.

Watch Video - Conduit Box Installation on the GS4

Check out our job openings

Free Online PLC Training

FREE Video Tutorials

FREE e-Newsletter

Automation Notebook

Product Literature

White Papers

News, Product and Training Bulletins

E-Books

Safe &

Secure

Safe &

Secure

We accept VISA, MasterCard, Discover, American Express, PayPal or company purchase orders.

Voted #1 mid-sized employer in Atlanta

Check out our

job openings

Loading...

Loading...