Cookies are not enabled on your browser.

Cookies are not enabled on your browser.Cookies are required for our site. Please enable cookies in your browser preferences to continue.

- Barcode / RFID / Vision

- Bulk Wire & Cable

- Cables (Terminated)

- Circuit Protection / Fuses / Disconnects

- Communications

- Drives & Soft Starters

- Enclosure Thermal Management & Lights

- Enclosures & Racks

- Field I/O

- HMI (Human Machine Interface)

- Hydraulic Components

- Motion Control

- Motor Controls

- Motors

- Pneumatic Components

- Power Products (Electrical)

- Power Transmission (Mechanical)

- Process Control & Measurement

- Programmable Controllers

- Pushbuttons / Switches / Indicators

- Relays / Timers

- Safety

- Sensors / Encoders

- Stacklights

- Structural Frames / Rails

- Tools & Test Equipment

- Valves

- Water (Potable) Components

- Wire & Cable Management

- Wire & Cable Termination

- Retired Products

Configuration Utilities

- PLC Family Selector

- P1000 PLC Systems

- P2000 PLC Systems

- P3000 PLC Systems

- ProductivityCODESYS

- CLICK PLC Systems

- Do-more® BRX PLC Systems

- LS-Electric® XGB PLC Systems

- Productivity®Open Systems

- Datalogic® Safety Light Curtains

- LS-Electric® Servo Systems

- Nitra® Pneumatic Grippers

- Object Detection (Sensors)

- PAL Controller Configurator

- Precision Gearbox Selector

- Protos X® Field I/O

- Pyrometers Selector

- Quadritalia® Modular Enclosures

- Stellar® Soft Starters

- Stepper System Selector

- SureFrame T-slot Extrusion

- SureMotion® XYZ Gantry

- SureServo2® System Selector

- SureStep® Linear Actuators

- Timing Belts & Pulleys

- Werma® Stacklights

- ZIPLinks

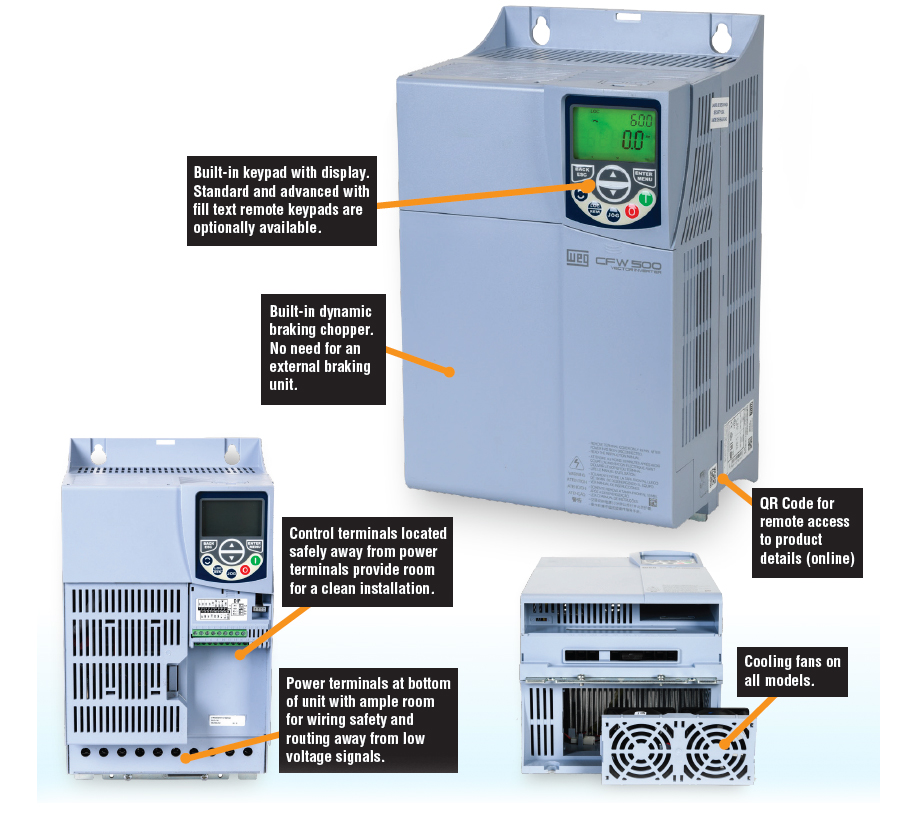

WEG CFW500 High-Performance AC Drives

A closed-loop flux vector VFD you can buy direct

The WEG CFW500 series is a high-performance AC variable frequency drive that supports closed-loop flux vector speed control as well as torque control modes. Until now you had to wait up to several months when ordering drives with high-performance features such as these. Now you can get them shipped straight to you from AutomationDirect.

Applications

- Centrifugal pumps

- Roller tables

- Winders

- Conveyors (excellent for high-speed metering and gapping belts)

- Tensioners

- Fans & blowers

- Mixers

- Extruders

- Granulators

- Cutting & welding machines

- Commercial dryers

- Rotary filters

Additional CFW500 Features

The CFW500 line of VFDs have the following features:

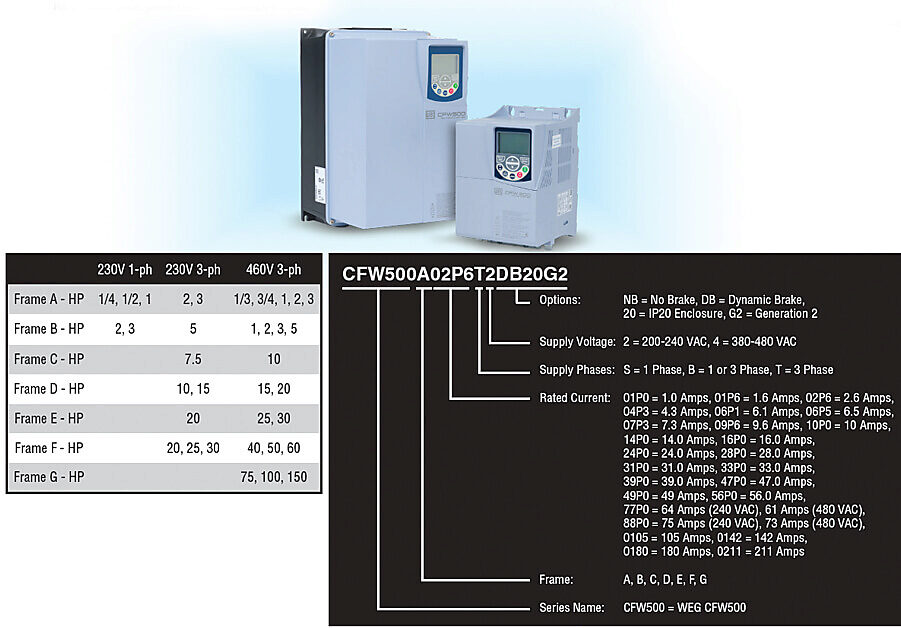

- Broad offering from 1/4 to 150 hp

- 200-240V (single-phase/3-phase and 3-phase only models) and 380-480V input voltage

- 230VAC: three-phase up to 30Hp, single phase input up to 3hp (up to 20hp for IP66/NEMA 4X models)

- 460VAC: three-phase up to 150HP (up to 30hp for IP66/NEMA 4X models)

- IP20 with NEMA 1 conduit box options and models that are IP66/NEMA 4X rated with or without integral disconnect

- Speed and torque control down to 0 (zero) rpm

- Precision of 0.01% for speed control

- DIN rail (35mm), A, B, and C frame, or surface mounting with screws on all frame sizes

- Frame F and G can be flange mounted

- Same programming as other WEG VFDs including CFW300 and CFW100

- Built-in SoftPLC

- Scalar, Vector Control (Senseless and closed-loop with encoder feedback) & VVW PM (suitable for fan, Pump and compressor)

- 0 to 500 Hz output frequency

- 2.5 to 15 kHz adjustable switching frequency (5 kHz standard)

- PID with sleep mode

- Flying start / ride-through

- Built-in 24Vdc Power supply (max. 150 mA)

- Built-in RS-485 (Modbus RTU) communication

- Four isolated programmable digital inputs

- One programmable relay output (1NO, 1NC, 240vac 0.5A)

- One programmable transistor output

- One isolated programmable analog input (0-10V, 0/4-20mA)

- One isolated programmable analog output (0-10V, 0/4-20mA)

- Protective features: Over current (Phase-Phase short circuit in the output or phase-ground short circuit in the output), Under/overvoltage, overtemperature in heatsink, motor overload, IGBT overload and external fault

- Control features: Linear and "S" ramp acceleration and deceleration, local/remote control, DC braking, torque boost, motor slip compensation, electronic pot, preset speeds, adjustable V/Hz profile, maximum and minimum adjustable frequency limits, two skip frequencies, adjustable output current limit, JOG, ride-thru, flying start and PID regulator

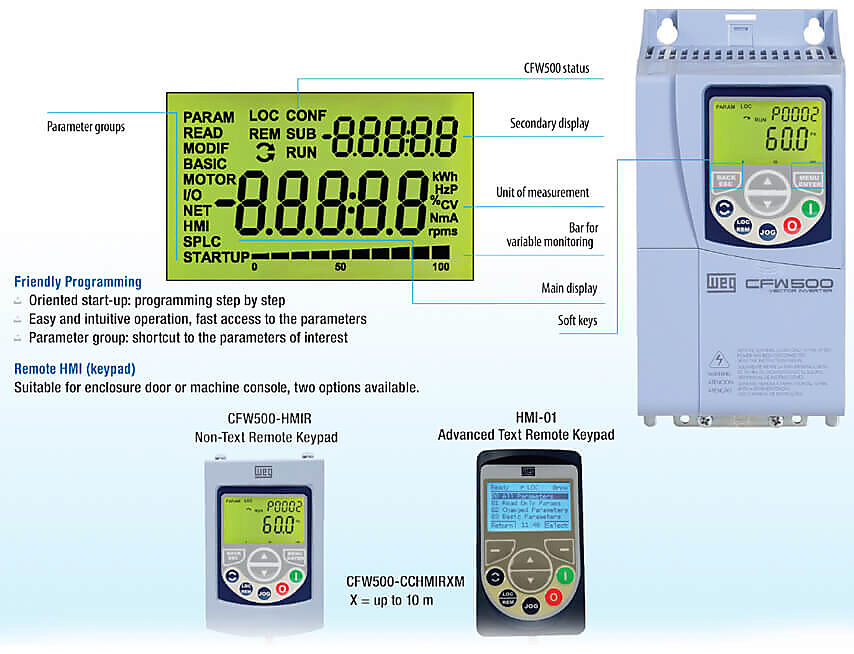

- Same keypad with backlight as of CFW500 product line with Main display line, secondary display line and bar graph display

- Ambient: 14°F (-10°C) to 104°F (40°C), 3300ft (1000m) altitude, 5-95% humidity, non-condensing

- WPS compatible

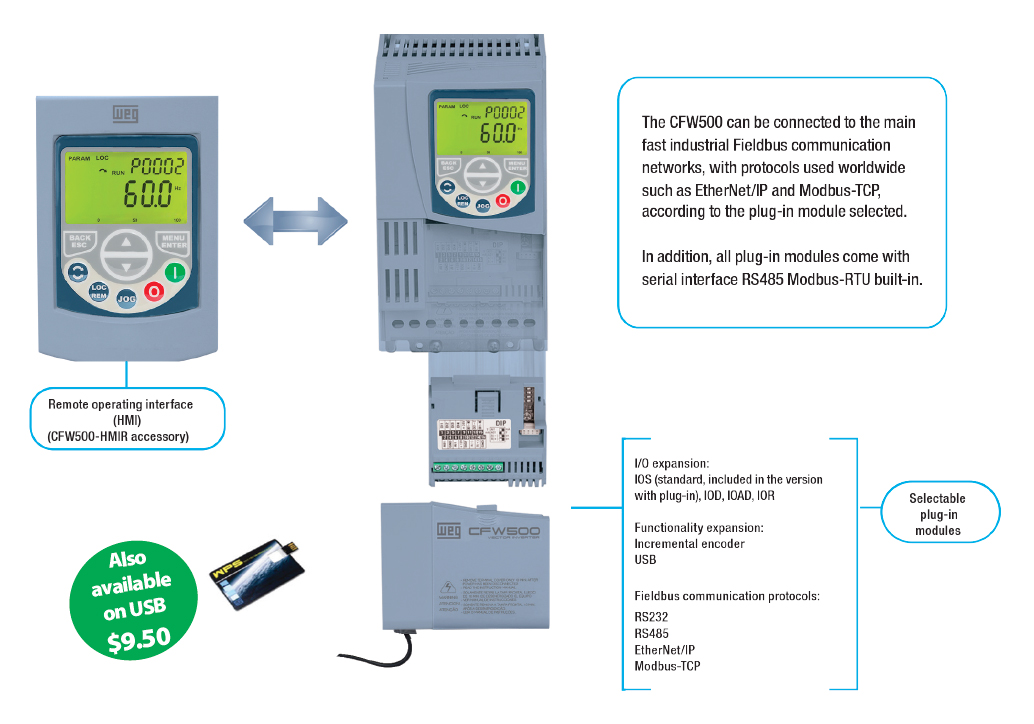

Flexibility and Performance

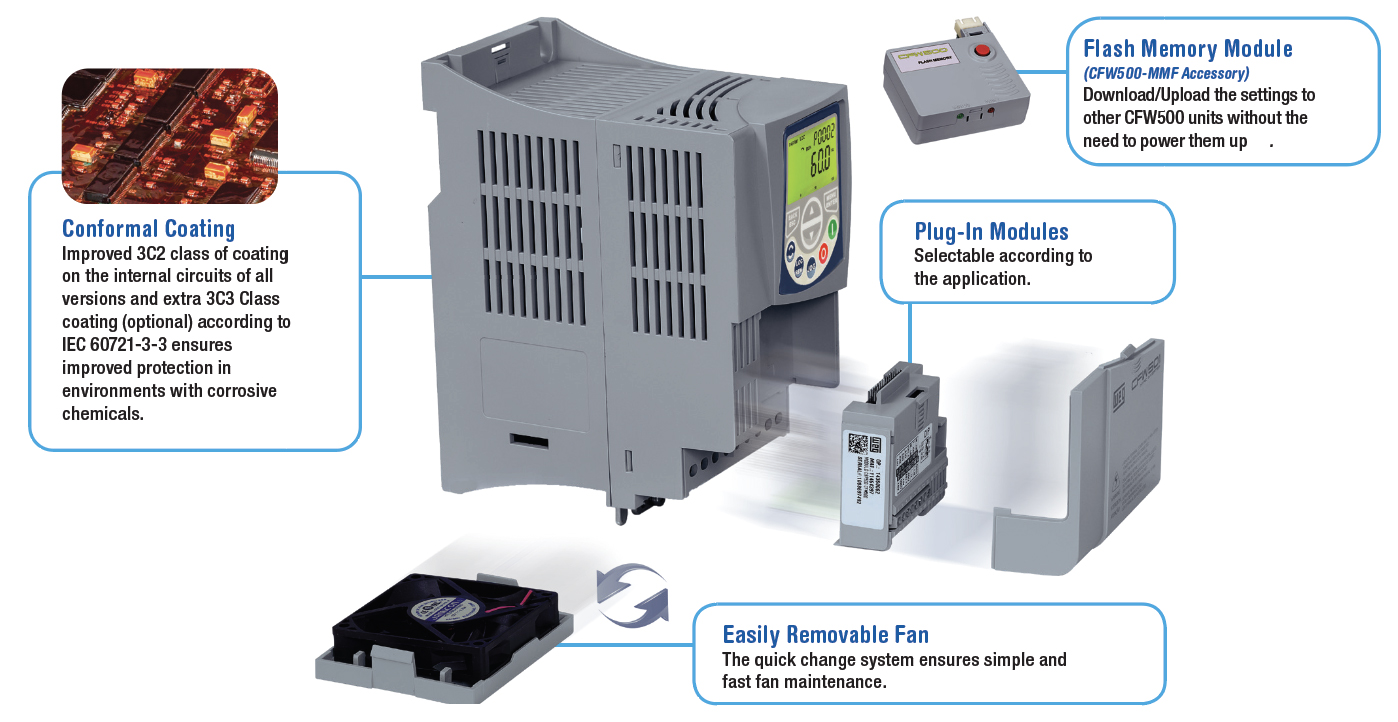

This VFD gives the user the possibility to choose the plug-in module that best fits his application, or to use the standard version, that comes with the CFW500-IOS plug-in module. All plug-in modules comes with one RS485 port as standard.

The installation of the CFW500 is simple and its configuration and operation is intuitive with the navigation menus of the operating interface (HMI) with built-in LCD display. By using the flash memory module, it is possible to download the existing setting from one CFW500 to other units without powering them up.

[Click to enlarge in new tab]

Human-Machine Interface (keypad)

Display up to three variables at the same time, selected by the user.

Safety Advantages

Used to reduce risk and to guarantee the safety of personnel and environment if there is a hazardous event due to a fault in operating machines. The embedded safety functions STO and SS1 provide machine builders a cost-effective solution to design protective measures and reduce the risk from unexpected and hazardous movement in industrial machines and processes.

- Safety functions integrated in the CFW500 drive, making easier to comply with the machine and application safety requirements

- Less components, no need for additional wiring, saving space and installation costs

- Easier installation, commissioning and maintenance

- No electromechanical components, meaning faster responses and higher degree of productivity

- Due to the high safety performance level SIL3, the CFW500 with Safety module may avoid the use of external safety relays for cables and emergency pushbuttons monitoring

Safety Functions

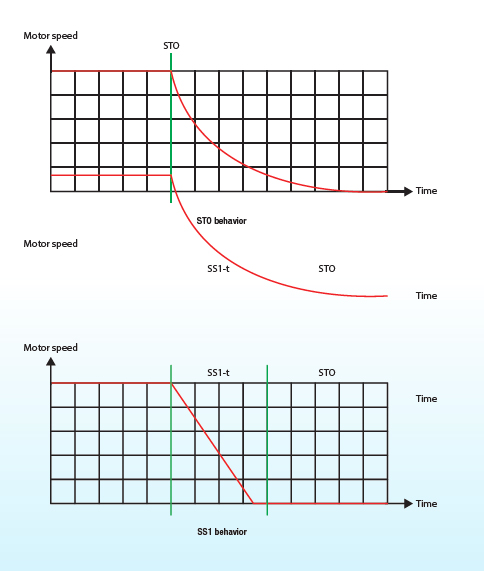

STO (Safe Torque Off)

This function immediately switches off the drive output to the motor, disabling the supply of torque-generating energy. STO is also used to prevent an unexpected startup of machinery or for an emergency stop, fulfilling stop category 0 (IEC 60204-1).It is applicable if the motor can be brought to a standstill in a sufficiently short time by the load torque or friction or where motor coast to a stop is not relevant to safety.

SS1 (Safe Stop 1)

This function enables motor deceleration and then, after a delay time, activates the STO function. SS1 can be used to implement a controlled stop and then removal of power, fulfilling stop category 1 according to IEC 60204-1. This function is used when, in the event of a safety related fault, the drive must stop as quickly as possible and then enter the STO state. The stopping of a drive by means of SS1 function reduces the risk of danger, eliminates the need of external safety timers, increases the productivity of a machine and allows safety clearances in a machine to be reduced. The reason is the active stopping of the drive as compared with the use of the STO function only.

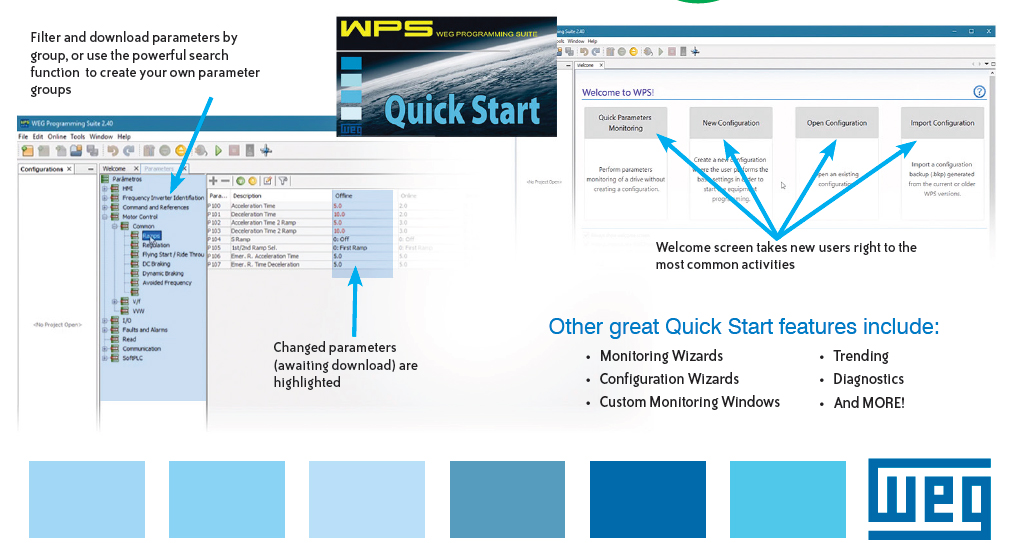

Free WPS Programming Suite Software

That's right! The WPS software is a free download. This is a fully featured software suite for drive configuration, monitoring AND for programming the built-in PLC - it's all in one easy-to-use package.

Check out our job openings

Free Online PLC Training

FREE Video Tutorials

FREE e-Newsletter

Automation Notebook

Product Literature

White Papers

News, Product and Training Bulletins

E-Books

Safe &

Secure

Safe &

Secure

We accept VISA, MasterCard, Discover, American Express, PayPal or company purchase orders.

Voted #1 mid-sized employer in Atlanta

Check out our

job openings

Loading...

Loading...