Cookies are not enabled on your browser.

Cookies are not enabled on your browser.Cookies are required for our site. Please enable cookies in your browser preferences to continue.

We will close at 3PM ET on Tuesday, December 23rd. Please note our shipping changes for Tuesday.

Freight shipments, FedEx ground and customer pickup deadline is 11:00AM ET. FedEx Priority (and free 2-day delivery) cutoff will be 1:00 PM ET. No UPS shipping will be available on Tuesday.

Drop ship vendors, Saginaw, Husky and Weigmann will also be closed Friday, Dec 26th.

Merry Christmas to each of you and your families from the employees of AutomationDirect

- Barcode / RFID / Vision

- Bulk Wire & Cable

- Cables (Terminated)

- Circuit Protection / Fuses / Disconnects

- Communications

- Drives & Soft Starters

- Enclosure Thermal Management & Lights

- Enclosures & Racks

- Field I/O

- HMI (Human Machine Interface)

- Hydraulic Components

- Motion Control

- Motor Controls

- Motors

- Pneumatic Components

- Power Products (Electrical)

- Power Transmission (Mechanical)

- Process Control & Measurement

- Programmable Controllers

- Pushbuttons / Switches / Indicators

- Relays / Timers

- Safety

- Sensors / Encoders

- Stacklights

- Structural Frames / Rails

- Tools & Test Equipment

- Valves

- Water (Potable) Components

- Wire & Cable Management

- Wire & Cable Termination

- Retired Products

Configuration Utilities

- PLC Family Selector

- P1000 PLC Systems

- P2000 PLC Systems

- P3000 PLC Systems

- ProductivityCODESYS

- CLICK PLC Systems

- Do-more® BRX PLC Systems

- LS-Electric® XGB PLC Systems

- Productivity®Open Systems

- Datalogic® Safety Light Curtains

- LS-Electric® Servo Systems

- Nitra® Pneumatic Grippers

- Object Detection (Sensors)

- PAL Controller Configurator

- Precision Gearbox Selector

- Protos X® Field I/O

- Pyrometers Selector

- Quadritalia® Modular Enclosures

- Stellar® Soft Starters

- Stepper System Selector

- SureFrame T-slot Extrusion

- SureMotion® XYZ Gantry

- SureServo2® System Selector

- SureStep® Linear Actuators

- Timing Belts & Pulleys

- Werma® Stacklights

- ZIPLinks

Analog Capabilities

Tremendous Processing Power

The P2-550 CPU’s lightning fast processor executes your ladder code quickly and efficiently!

Sub-millisecond Scan Times:

The performance benchmark used for testing the Productivity2000 includes 3K Boolean logic + 240 I/O points (the maximum amount of discrete I/O that will fit in a 15-slot base. The Productivity2000 P2-550 CPU executes this test with a scan time of 470 microseconds.

Powerful and Efficient:

This processing power combined with 50Mb total memory means that there are practically no limits on the number of timers, counters, & PID loops for your application. And the powerful task management tools built-in to the software help you streamline your ladder code for maximum efficiency.

Communications Workhorse:

Supporting five built-in communication ports simultaneously, the P2-550 CPU handles all your communications needs without slowing the I/O throughput since it doesn't have to exchange data with separate communication modules over the backplane.

Incredible I/O Capabilities

The P2-550 has an Ethernet port on-board, and EtherNet/IP support built-in - so there is no need to spend extra $ or waste a slot for Ethernet communications. And the wide variety of I/O modules , the ability to hot-swap I/O modules , and the innovative diagnostic capabilities of the analog modules assure that the Productivity2000 can handle your system's requirements for most any application.

At only $365.00 , the P2-550 is truly a high-value CPU!

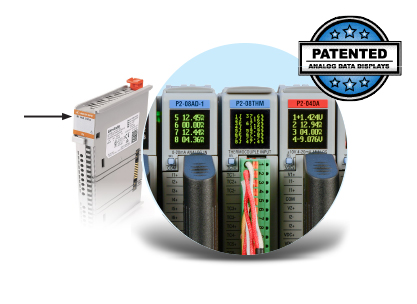

3. Messages displayed vs blinking lights

The analog and temperature modules for the P2000 have a patented built-in OLED display on the front of the module. Get accurate process variable data (current, voltage and temperature) as well as system diagnostics in real time, just by reading the display on the Productivity2000 hardware. No tools required! That's much better than the significantly higher priced Allen Bradley temperature (or analog) module's blinking light.

Support information at your fingertips!

Pull down the QR tab from top of I/O module, and scan with your smart phone or tablet QR app to get the latest updated specifications for that module.

Does this sound familiar: You're in the field and realize you have no documentation, no manual and the inserts and documentation that were included with the PLC when it was purchased were not kept in the panel.

Now you can quickly scan the QR code on any I/O module with a standard QR Code Reader on any smart phone or tablet and instantly you have installation details, module specifications and wiring diagrams at your fingertips!

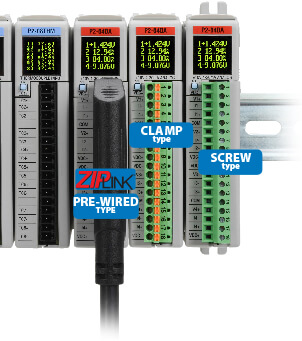

9. Choose the wiring option YOU prefer

Productivity2000 is all about productivity, even down to the wiring. Three wiring options are available to better serve the specific needs of your application. Two terminal blocks; one screw type, and one clamp type are available, as well as our ZIPLink wiring system. Why spend the time wiring each I/O point to a terminal when you can get them prewired? ZIPLink pre-wired cables and terminals not only save you valuable time but also keep your installation clean and efficient, which helps when troubleshooting, and ZIPLinks use half the space at a fraction of the cost of standard terminal blocks. Simply snap the ZIPLink connector to the I/O module, connect your field wiring to the ZIPLink terminal and your wiring job is done.

AutomationDirect strongly recommends the use of ZIPLink cables and wiring modules, which eliminate the need for hand wiring of I/O modules to terminal blocks. In fact, many of the Productivity2000 I/O modules do not include the terminal blocks for direct connection of I/O.

Note: ZIPLinks are available for most, but not all I/O modules.

ZIPLink Module

ZIPLink Pre-Wired

ZIPLink Pigtail Cable

"No Problem" programming is programming without restrictions.

The Productivity2000 is a tag name based controller which allows for more freedom and flexibility than fixed-memory controllers.

- Does your application need 2000 timers but only 15 counters? No problem!

- Or maybe it needs 4000 real numbers and only 30 integers? No problem!

What about connectivity? No problem there either, with most Productivity CPUs you can choose to program via the Ethernet port or use the plug and play USB Port. Need to incorporate an HMI/SCADA interface? Problem solved! Easily import your tag database into HMI/SCADA software such as C-more for trouble-free development. Improved documentation, faster troubleshooting, reduced development time, easy setup and an overall better programming experience all at an unbeatable price!

No Arbitrary Limits Either:

The Productivity2000's fast processor and programming environment free you from many arbitrary and fixed limits that many other PLC/PACs impose. With no practical limit on the number of PID loops, timer or counter commands, programmers are able to take full advantage of the power of your Productivity Series controller.

- No limits on PID loops*

- No limits on Counters*

- No limits on Timers*

*Limited only by the available memory in the PLC.

So you can be productive, not limited by your PLC software.

Wide Variety of I/O Modules

Productivity2000 offers 8-point and 16-point versions of the DC discrete inputs and discrete outputs (in sinking or sourcing), and 8 or 16-point AC modules, relay outputs and Specialty Modules (including High-Speed I/O Modules and motion controllers). Analog Inputs, Outputs, and Combination modules are also available - all with 16-bit resolution. Click a module below to see the full range of each type.

Analog Inputs

4, 8 or 16-point; voltage, current, RTD, and thermocouple. 16-Bit resolution.

Prices start at $217.00

Analog Outputs

4, 8 or 16-point; voltage or current; sinking or sourcing. 16-bit resolution.

Prices start at $212.00

Analog Combos

Combination of analog inputs and outputs on the same module. 16-bit resolution.

Prices start at $456.00

Motion & High Speed

2 Channel High-Speed Input, 2 Channel High-speed Output, 2 Channel High-speed Counter, and 4 Channel Pulse Width Modulation Module.

Prices start at $120.00

Specialty & Communications

4-port Serial Modules

Prices start at $242.00

Motion Controllers up to 4 axes, 1 MHz maxiumum switching frequency, up to 24 high-speed input points, 4 differential encoder inputs, 12 high-speed output points, and 4 differential output.

Prices start at $331.00

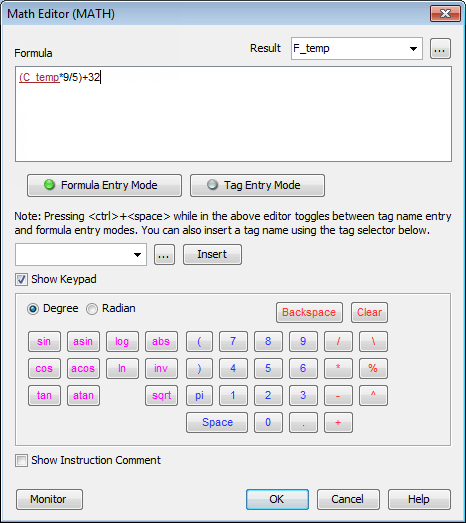

Nimble Math Instructions

The Productivity Suite makes mathematical operations a cinch. Simply type your formula into the formula box area, or use the calculator style keypad to enter equations. Insert tagnames wherever they are needed, and make sure to enter a tagname for the result. You can type the tagnames or use the tagname chooser to look up a specific tag and insert it. How much more productive could this make you?

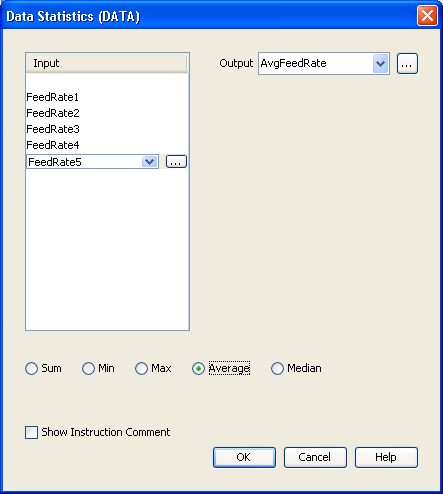

In addition to the Math Instruction, the Productivity Suite offers the Data Statistics instruction shown below for calculating sums, averages, or median values or for determining the Min. or Max. value from a group of tags. Simply type or select your tags from the pulldown list, and enter a tag for the output.

8. Hot-swappable I/O - keeps you up and running!

Avoid costly shutdowns, production losses and long start-up operations with Productivity2000 hot-swappable hardware.

That's right, all the I/O modules for the Productivty2000 are hot-swappable! When used appropriately, this capability can save time and help avoid long start-up operations or other down-time related inconveniences. Now that can make you more productive!

Of course, it's up to the system designer to determine if hot-swapping is appropriate and safe for each application.

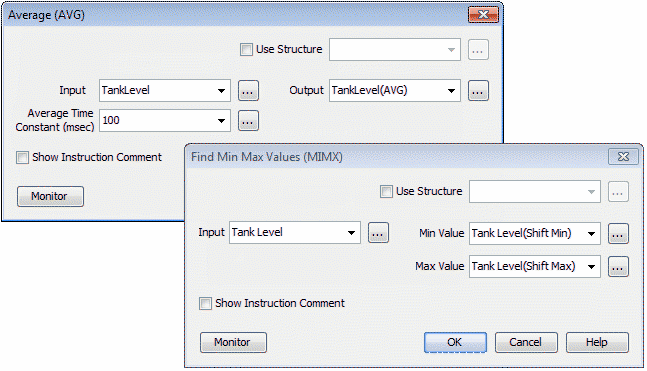

Application Specific Instructions

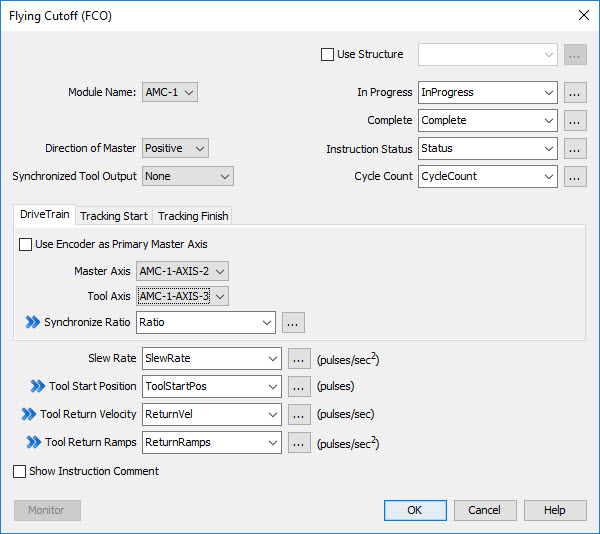

In Productivity Suite there are so many time-saving instructions, even application-specific instructions like Flying Cutoff, and they all have one thing in common - their "fill-in-the-blank" programming method. This method makes it easy to configure tasks that used to require a whole bunch of program code. With Productivity Suite you just fill in the blanks. How productive is that! This style of programming is offered for even the more complex functions - coordinated motion profiles, array functions, communications, PID, the list goes on and on.

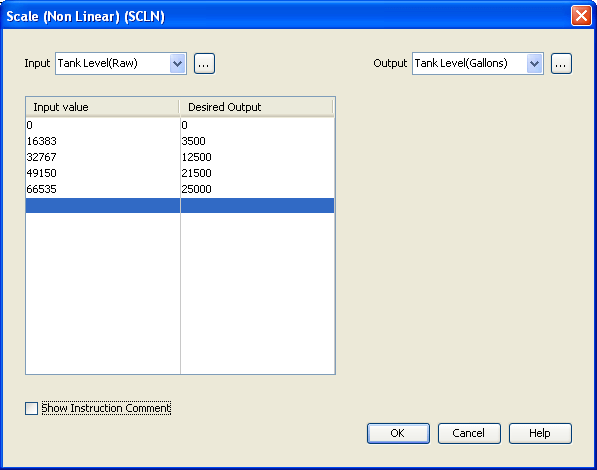

In this non-linear scaling example, the volume of the cylindrical tank needs to be determined based on the measured height of the fluid:

With the SCLN instruction it's a simple matter to enter a few pairs of values, and the Productivity2000 interpolates between the points:

Of course with this particular example additional pairs of values could be used to improve the accuracy of the conversion.

Check out our job openings

Free Online PLC Training

FREE Video Tutorials

FREE e-Newsletter

Automation Notebook

Product Literature

White Papers

News, Product and Training Bulletins

E-Books

Safe &

Secure

Safe &

Secure

We accept VISA, MasterCard, Discover, American Express, PayPal or company purchase orders.

Voted #1 mid-sized employer in Atlanta

Check out our

job openings

Loading...

Loading...